Quick access to IMA Sectors:

Pharma | Food & Dairy | Confectionery | Tea & Beverage | Coffee | Personal & Home Care | Tissue & Nonwoven | Automation | Tobacco | E-Commerce |EF600-825

EF600 and EF825 are FFS machines with an exceedingly high output, a benchmark in terms of durability. An ample variety of packaging shapes and materials is possible, and - thanks to a wider bottom web - scrap rate is significantly less.

EF600 and EF825 are FFS machines with an exceedingly high output, a benchmark in terms of durability. An ample variety of packaging shapes and materials is possible, and - thanks to a wider bottom web - scrap rate is significantly less.

The reliable, heavy duty FFS machine

These are machines to opt for when high outputs are required along with worry-free operation and impressive reliability. EF600 and EF825 handle a wide range of dairy products and can process innovative thermoformed shapes and designs.

Product changeover is quick and easy, and labelling techniques include straight or conical IML as well as in-mould sticker labels.

Cups can be designed cost-effectively with many labelling solutions and freedom of cup geometry. Not only a marketing tool, the label also strengthens the cup’s sidewall stability, enabling a thinner bottom web resulting in higher sustainability.

EF600-825 Highlights

Products to be filled

Filling Solutions

Labelling Solutions

Cup Shapes

- Technical Data

- Machine Layout

| TECHNICAL DATA EF 600-825 | ||

| Model | EF600 | EF825 |

| Cup material width | 618 mm* | 858 mm* |

| Usable width | 658 mm* | 838 mm* |

| Draw off length | 300 mm | 300 mm |

| Forming depth | 100 mm | 130 mm |

| * +60 mm with spike chains | ||

| Materials | ||

| PS, PET, PP and multilayers such as PS/PE, PS/PETG, PS/EVOH/PE, PP/EVOH/PP | ||

| TYPICAL OUTPUTS | ||

| EF600 | ||

| Yoghurt cups 63 x 63 mm, with w.a. label, 4×8 – 30 cycles/min. | 57,600 cups/h | |

| Fresh cheese cups with w.a. label 49 x 49 mm, 4×12 – 30 cycles/min. | 80,400 cups/h | |

| EF 825 | ||

| Yoghurt cups 63 x 63 mm, with w.a. label, 4×12 – 30 cycles/min. | 86,400 cups/h | |

| Standard Equipment | ||

| Components | Controller and servo motors ELAU, Pneum. FESTO, HMI 15″ | |

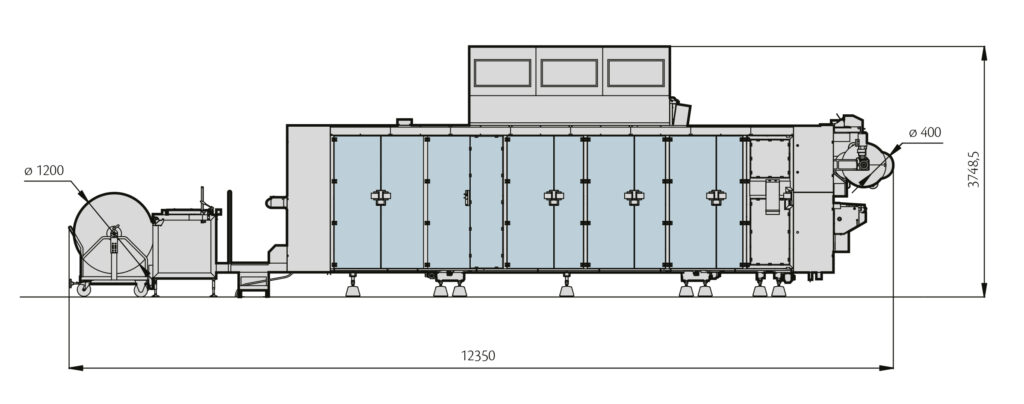

| Standard configuration | EF600 Bottwom web reel Ø 1200 mm Lid reel Ø 400 mm Label reel Ø 600 mm ERCA Chains with grippers and magnetic drive, labelling with tilting mold, pneumatic heating section on 6 pitches, exit conveyor with Intralox chains. EF825 Bottom web reel Ø 1600 mm Lid reel Ø 400 mm Label reel Ø 600 mm ERCA Chains with grippers and magnetic drive, labelling with barel 4 molds or tilting mold, pneumatic heating section on 6 pitches, exit conveyor with Intralox chains. |

|

| Hygiene class | Clean | |

| Options | ||

| Hygiene class | Ultra-clean*, Aseptic* | |

| Labelling | Any kind of labelling, labelling for conical cups, 2 label heights, automatic splicing | |

| Chains | ERCA spiked chains | |

| Fillers | Up to 3 fillers | |

| * Depending on customer specification | ||