Quick access to IMA Sectors:

Pharma | Food & Dairy | Confectionery | Tea & Beverage | Coffee | Personal & Home Care | Tissue & Nonwoven | Automation | Tobacco | E-Commerce |HAMBA BK II

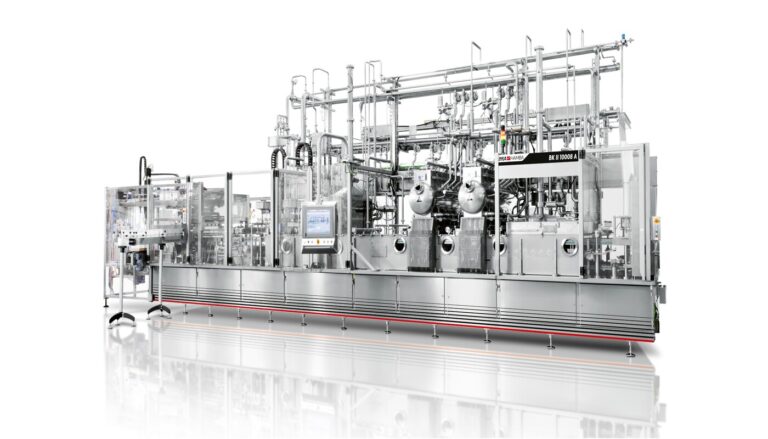

Blending the solid construction and consolidated design of the BK II with most advanced technologies, this flexible cup filling solution will adapt simply to suit countless customer requirements.

Blending the solid construction and consolidated design of the BK II with most advanced technologies, this flexible cup filling solution will adapt simply to suit countless customer requirements.

The strength of experience.

Based on the design of the proven HAMBA BK concept, this filling and sealing machine for pre-made cups stands for more efficiency, availability and flexibility. The BK II is controlled via a vertical shaft and curves. The machine can be designed with up to 12 lanes and is available as a single cycle, double cycle or even with two (2) preinstalled formats. The HAMBA BK II is also suitable for aseptic filling. Robustness and a compact design characterize this type of machine.

The HAMBA BK II handles all types of yoghurt, curd, aerated products, desserts, jelly-products and cereals.

When fitted with a special filling system, the HAMBA BK II also fills fat based products including margarine and spreads, while further food or non-food pasty products can be dealt with on demand.

HAMBA BK II Highlights

Products to be filled

Filling Solutions

Cup formats

- Technical Data

| TECHNICAL DATA HAMBA BK II |

||||

| Model | Cups per cycle | Round (max. Ø) | Height (max.) | Nominal output |

| 4M* | 4 | 127 mm | 130 mm | up to 9.600 cups/h |

| 6M* | 6 | 127 mm | 130 mm | up to 14.400 cups/h |

| 8 | 8 | 95 mm | 130 mm | up to 19.200 cups/h |

| 10 | 10 | 95 mm | 130 mm | up to 24.000 cups/h |

| 12 | 12 | 75 mm | 130 mm | up to 28.800 cups/h |

| 6/6 | 12 | 130 mm | 130 mm | up to 28.800 cups/h |

| 8/8 | 16 | 95 mm | 130 mm | up to 38.400 cups/h |

| 10/10 | 20 | 95 mm | 130 mm | up to 48.000 cups/h |

| 12/12 | 24 | 75 mm | 130 mm | up to 57.600 cups/h |

| * square and rectangular cups can also be handled | ||||

| TYPICAL MATERIALS | ||||

| Cups | Pre-made cups made of paper, PET, PP, PS, K3 or compound materials* | |||

| Lids | Pre-cut lids made of aluminium foil, PET or PP* | |||

| Snap-on lids | Pre-made snap-on lids made of PET, PP, PS* or filled snap-on-lids |

|||

| * other material combinations on request | ||||

| STANDARD EQUIPMENT | ||||

| Cup feed and decontamination | Cup destacker and insertion, cup control, cup decontamination by means of H2O2, cup lifting and ejecting onto discharge conveyor (alternatively an integrated packer can be installed) | |||

| Filler | Free space for pre-filler, main filler (CIP, SIP, nozzles, level controls) | |||

| Lid | Lid applicator with H2O2 decontamination and sealing station | |||

| Others | Cup tightness control, free space for coding (laser or linear unit for inkjet) | |||

| Hygiene class | Ultra-clean (VDMA III+IV) | |||

| OPTIONS | ||||

| Hygiene class | Aseptic (VDMA V) | |||

| Filler | Pre-filler, pre- and post filler, side-by-side filling, twisted filling, spot filling | |||

| Control system | Rockwell Automation | |||

| Others | Cup pole feed in various designs and positions, particle extraction, sealing/punching of lidding material from the reel (roll stock), coding, snap-on lid station and infeed, end-of-line packaging equipment | |||