Quick access to IMA Sectors:

Pharma | Food & Dairy | Confectionery | Tea & Beverage | Coffee | Personal & Home Care | Tissue & Nonwoven | Automation | Tobacco | E-Commerce |CPH2

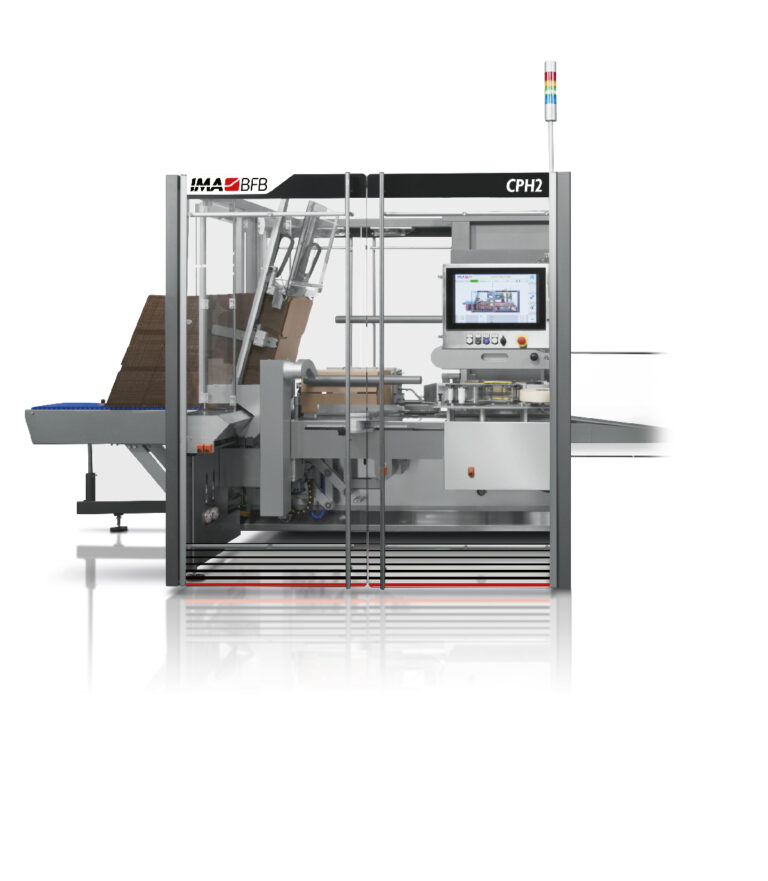

Medium speed case packer designed to handle the widest range of products and materials used in pharmaceutical, with maximum ease of use and total control of the packaging process

Medium speed case packer designed to handle the widest range of products and materials used in pharmaceutical, with maximum ease of use and total control of the packaging process

Fit for the future

Fully automatic side loading case packer designed to satisfy all of your current and future case packing requirements.

The machine has been built to maximize efficiency and ease of use in an ever increasingly demanding work place, to guarantee complete line clearance and to ensure total access to all modules.

The CPH2 is designed to ensure total control throughout all stages of the serialization process.

Flexibility, maximum efficiency, total access and total control make the CPH2 a casepacker of new generation.

CPH2 Highlights

Case Packer - Palletizer integrated versions

CPH2 is available in different palletizer-integrated versions, according to the output required:

CPH2-RP2

With automatic replacement of the full pallet and case buffering during pallet replacement or with two pallet stations; once one pallet is complete, the robot starts loading the second pallet

CPH2-RP4

With 4 pallet stations for greater autonomy. When the pallet is complete, the automatic transport moves the pallet to the exit area and replaces it with an empty one.

- Technical Data

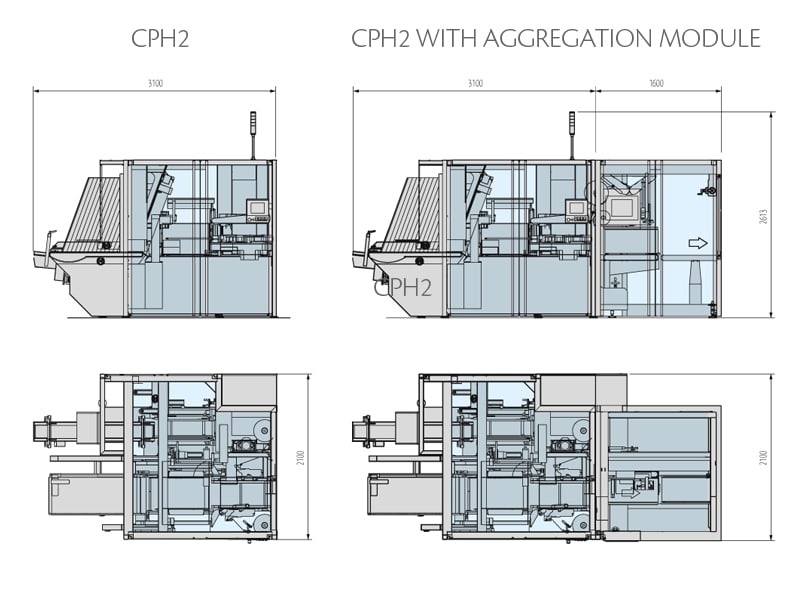

- Machine Layout

| CPH2 TECHNICAL DATA | |||

| Case dimensions | A | B | C |

| Min. | 220 | 100 | 90 |

| Max. | 600 | 400 | 400 |

| Product dimensions | a | b | c |

| Min. | 25 | 22 | 60 |

| Max. | 590 | 70/150 | 220 |

| Speed | 10 cases/min. | ||