IMA TEKNOWEB

With more than 20 years fully dedicated as main contractor for the nonwovens industry, we provide state of the art solutions to manufacture wet wipes, absorbent hygiene products, and personal protection equipment.

No one is too far or too small to access to our solutions.

![]()

Your perfect match for wet wipes plants.

Based in Palazzo Pignano, Italy, IMA Teknoweb is world leader of complete full production lines for wipes. Its longstanding expertise belongs to designing and manufacturing automatic machines dedicated to disposable nonwovens, specifically wet and dry wipes for which the Company distinguished worldwide for its cutting-edge machines.

As main contractor of complete solutions, IMA Teknoweb covers the entire transformation cycle, from converting through to palletizing. Minimum Total Cost of Ownership, maximum integration, and high performance for each industrial customer are always a priority in the design of its machines.

IMA Teknoweb has introduced new technologies to expand its nonwoven solutions portfolio, aligning into three main segments:

- Wipes

- Absorbent Hygiene Products (AHP)

- Personal Protection Equipment (PPE)

IMA Teknoweb integrates competencies from specialists in each specific fabrication step and delivers full solutions with a “one-stop” approach.

OUR MAIN REFERENCE MARKETS

- WIPES

- AHP | Absorbent Hygiene Products

- PPE | Personal Protection Equipment

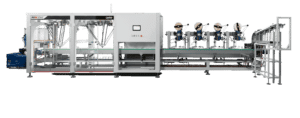

WIPES | Converting and packaging solutions

IMA Teknoweb is fully committed to the manufacture of wet and dry converting and packaging machines, serving as the sole contractor for complete production lines. With the capability to achieve market-leading speeds of up to 600 packs/minute with proper stacking and offering a wide range of folding options, IMA Teknoweb caters to various wipe types, including: personal care items (baby wipes, cosmetic wipes for makeup removal and masks, bathing gloves) medical items (disinfectant wipes for surfaces), household items (colour catchers and floor mops), and industrial wipes.

IMA Teknoweb converters can manufacture a wide spectrum of wipe shapes, including:

- Flat

- Cross

- Rolled

- Individual

Additionally, our disinfectant wipes machines, compliant with ATEX standards, enable the production of alcohol-soaked wipes.

Thanks to the integration of the wide packaging expertise belonging to the IMA Group, all IMA Teknoweb converting equipment can be completed with primary and secondary packaging solutions, including flow packs, trays, cans, and bundles. The full array dedicated to the end-of-line include cartoners, case packers, tray packers and wrap-around machines.

AHP | Absorbent Hygiene Products Solutions

The absorbent mats market has seen a rise in the latest years; such products are dedicated to a personal care use, known as underpads, catching leaks that may occur in beds, especially taking in consideration elderly people. But they can be employed for pet care as well. To produce the finest quality of absorbent mats, IMA Teknoweb introduced Ocean. It runs a 4 and 5-layer pad with an innovative and patent pending core formation process. It allows even and homogeneous distribution of fluff all over the core area, ensuring minor costs to the producer due to the optimization of the absorbent material. Moreover, safe core embossing provides the ultra performing pad at the highest level of the market.

PPE | Personal Protection Equipment Solutions

After quickly responding to the widespread need of protective masks by designing and supplying in three months the IMA FACE 400, a fully automatic high-speed line for the manufacture of surgical masks, IMA Teknoweb developed a well-balanced solution for PPE production, such as respirators for professional use with or without exhalation valve.

IMA Teknoweb’s line FACE 400D is designed for the production of fish-shape head loop FFP2/3 – N95 respirators up to 5 layers of material.

This extremely reliable technology works up to 300 ppm. The same line, with an optional module, can also manufacture respirators with exhalation valve in line placed in the front panel for heavy duty use in foundry, glass & wood industries, painting shops, construction, pharma, and all sectors where high effective air filtration is needed.

COMPLETE THE LINE WITH OUR PACKAGING SOLUTIONS

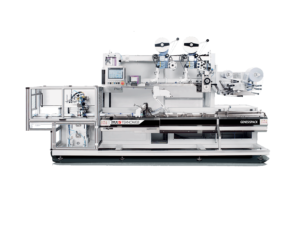

FLOW WRAPPERS

IMA Teknoweb, jointly with IMA Ilapak, continuously innovate their flow wrapping solutions to meet the evolving demands of various industries, focusing on product safety, hygiene, and appealing packaging.

LID APPLICATORS

A good wet wipes pack needs a sturdy “click” lid to seal in freshness and extend shelf life. To meet this need and offer a balanced solution, we developed a lidder capable of reaching speeds up to 150 packs per minute.

BUNDLERS

With a focus on sustainability, the wet wipes market is embracing 100% biodegradable nonwoven materials and exploring recyclable packaging options. Addressing this trend, IMA Teknoweb has introduced the MULTI50 handle applicator, reducing plastic usage in multi-bag packaging for complete recyclability.

FLOW WRAPPERS

In the nonwoven sector, popular packaging formats include pillow flowpacks and Quattro seal bags, catering to applications such as cosmetic cleansers, facial towelettes, and specialty wipes. These packages, ranging from 5 to over 30 wipes, are often displayed on shelves in trays. They feature various opening mechanisms, including peel and seal, rigid “click,” and flip-top molded fitment openers. To ensure freshness and moisture retention, precise technologies are applied in packaging machines by IMA Ilapak and IMA Teknoweb.

MACHINE PORTFOLIO

LID APPLICATORS

Our CM Series includes three machine versions: CM100 and CM120 and CM 150.

CM100 and CM120 are based on ABB flexpicker. Thanks to 2 or 3 picking points they can handle 2 or 3 plastic lids at the same time and reach up to 100 and 120 ppm, respectively. CM150 is equipped with two pick and place units and is capable to reach 150 packs per minute. Different types of lid magazines are available to cover all needs of autonomy, changeover time, automation. The CM150 offers precise placement with a single gripping head, outperforming multiple gripping heads. The precision is ensured by robots with joints free of mechanical play.

MACHINE PORTFOLIO

BUNDLERS

Our MULTI50 bundler minimizes material usage by holding wet wipe packets together with a single strip of material instead of full wrapping. Additionally, it enables the use of the same plastic material for both the adhesive tape and handle, facilitating easy recycling. Advanced technology, including a specialized photocell, eliminates the need for notches in film cutting, enhancing product presentation. Furthermore, a new vane belt with paddles ensures stable grouping of products during handle application, improving finished product quality. Processing packages on the side also increases stacking capacity from 4 to 5 or 6 as needed.

MORE INFO

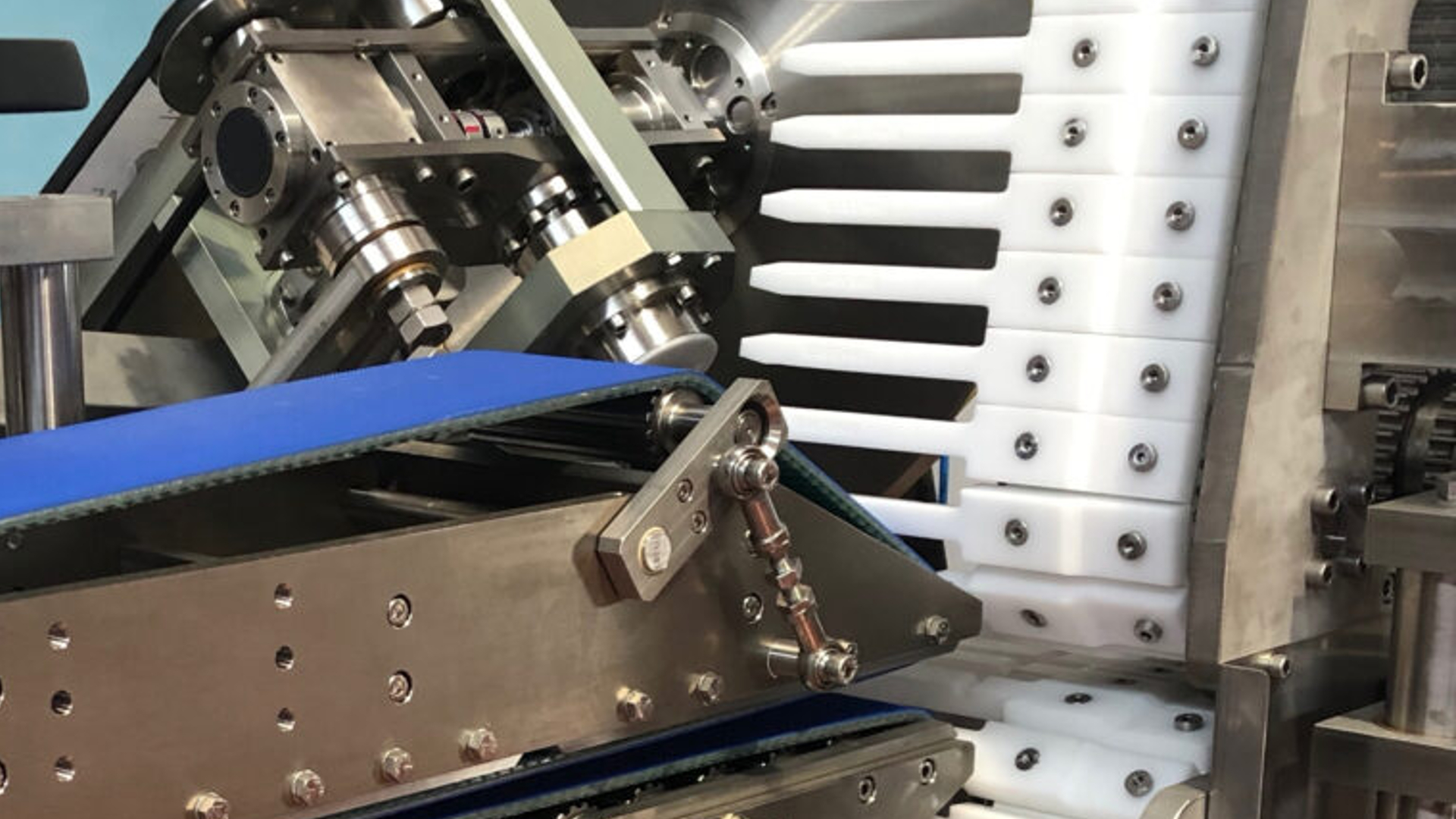

ROTO-ORBITAL CUTTING TECHNOLOGY

Wet wipes converting machines are usually equipped with 2 types of cutting units:

- a simple, low maintenance, less expensive pinch or scissor cutter

- a more mechanically complex roto-orbital disc saw

The first type is used when the ribbon to be cut is thin, usually less than 25 mm thickness. This is typical for lines shorter than 25 lanes and substrates thinner than 50 gsm. The second type is used in all the other cases, machines longer than 25 lanes, when the ribbon is thick and scissor cutter cannot guarantee a neat cut. In this case, a roto-orbital saw can cut easily and neatly 50 or also 80 lanes ribbon.

IMA Teknoweb improved its roto-orbital saw adding features which makes this unit faster (up to 600 cuts/min), more flexible (wider range of cutting length) and more reliable (less maintenance required). It consists of 2 rotating disc blades which match ribbon speed during cutting action and therefore guarantee a straight, neat, and squared cut.

It is based on patented system that includes a counter blade made of staves, placed in a straight belt. The counter-blade belt ensures high precision and reliability more than standard anvil drum.

Roto-orbital saw is currently proposed for all our long flat-fold lines (longer than 25 lanes) and is available for retrofitting existing machines.

IMA Teknoweb applies this techinolgy successfully also to dry wipes converting lines successfully. Main difference compared to wet wipes solutions is a lubrication device, which is necessary to limit temperature raise.

TEKNOWEB CONVERTING – NEXT • Wet wipe converting line

Delivers complete production plants for wet wipes, covering the entire transformation cycle from lotion fabrication, wipes converting and up to primary, secondary and tertiary packaging. We integrate competencies from specialists in each specific fabrication step and deliver full solutions with a “one-stop” approach.

Production facility:

Teknoweb Converting s.r.l.

Via dei Salici, 7

26020 Palazzo Pignano – Cremona (Italy)

Phone: +39 0373 951311

Email: info@teknowebconverting.com