IMA Teknoweb solutions for high-alcohol processing machinery.

Market demands have confirmed lately the increased request for disinfecting wipes for surface cleaning.

Despite these are produced either with or without IPA (Isopropyl Alcohol), consumers are more and more demanding for wipes with high alcohol content. This trend comes from the common experiences that alcohol is the most effective component to effectively disinfect a surface.

IPA (Isopropyl Alcohol) is the most used disinfectant for the manufacturing of wet wipes, but it brings into operations many challenges related to its toxicity and high flammability. To cope with this issue, IMA Teknoweb introduced some new features on its machines in order to mitigate the risks related to IPA handling.

When producing alcohol-soaked wipes with rates higher than 10-12%, there are some recommendations to follow, such as avoiding potentially explosive atmospheres, retaining the concentration of flammable liquids and avoiding ignition sources becoming effective. ATEX regulation translates these recommendations into actions and standards.

IMA Teknoweb’s explosion-proof converting line fully adhere to ATEX standards thanks to the development of a special equipment on its machines, which includes:

- An appropriate amount of ventilation in the cabinet to remove vapor

- A proper enclosure of the machine, safeguarding the operator

- A machine design able to reduce ignition causes, keeping mechanical parts at a low temperature and avoiding dangerous sparks

Designing and manufacturing converting machines to process IPA is not simple and the supplier must be selected carefully. IMA Teknoweb can offer several explosion-proof converting lines with different production capabilities, answering every manufacturer’s need to produce safely alcohol-soaked disinfecting wipes.

Discover our ATEX machine portfolio

Array

(

[rel_market] => Array

(

)

[clone_list] => Array

(

[0] => 7

)

[embed_iframe] =>

[form_price] =>

[contact] => sales@teknowebconverting.com, eleonora.sarti@ima.it

[no_index] =>

[thread_tag] =>

[tile_description] => FUTURA is a wet wipe folder extremely versatile, a reference for the whole market. It is totally configurable, matching any customer operation need for significant production volumes at reduced costs.

[tile_speed] => Up to 160/600 packs/minute

[cover_macro] => 2650

[cover_name_type] => txt

[cover_name] => FUTURA

[cover_descriptor] => Wet wipe converting line

[cover_focus_on] => 1

[news] =>

[thumbnail] => 2081

[tag_line] => Fast and precise.

[overview] => FUTURA is a wet wipe converting line for length-folded products, characterized by ultimate versatility.

By selecting the right options from its catalogue, FUTURA can match any requirement based on speed, product formula or even operation habits or constraints. It can be configured with a wide range of lanes, from 12 up to 100, and with pinch cutting (up to max 24/25 lanes) or roto orbital saw.

FUTURA can work with precut rolls or semi-jumbo, automatic splice, zero speed splices.

It can have integrated CIP, multiple folds. You can add vision quality systems, multiple wetting stations, specific features to handle delicate materials like flushable paper based nonwovens.

Production speed goes up to 720 cuts/minute (for low lanes number) with any type of substrate, even the most delicate paper-based flushables.

FUTURA can handle wipes width up to 380 mm, and even beyond with specific customization.

The totally configurable wetting system allows:

- one or more sanitary pumps with dedicated flowmeter, for perfect lotion dispensing on each wipe

- adjustable width or fixed width wetting bars, one per lane, to minimize lotion waste

- free choice of pre-fold wetting, post-fold wetting or both together, depending on substrate type

FUTURA can be provided compliant to ATEX (explosion-proof) standards, to safely produce and handle wet wipes soaked in Isopropyl Alcohol (IPA) or any other flammable liquids.

Some specific features (timing belt for die cut feeder belt, easy change folding plows, intermediate pressing belt) allow to reach performances which are the best in the market.

A plurality of packaging options (flow-wrapper) are available, in accordance to speed and volume needs.

This converting line is equipped with an extensive use of automation, in order to retrieve machine setting by HMI (Human Machine Interface)

Futura can process raw materials with low (or even zero) environmental impact, compared to the standard wipes composed of PP, PE or viscose. The sustainable material handled by Futura is composed of cellulosic fibers derived from wood pulp.

[highlights_on] => 1 [focus_on] => 1 [versions_on] => [addon_on] => [output_on] => 1 [technical_data] =>| FUTURA

WITH PINCH |

FUTURA

WITH ROTO ORBITAL CUT |

|

| Design speed (wipes/min) | up to 19.200 | up to 48.000 |

| Operating speed (wipes/min) | up to 18.000 | up to 48.000 |

| Cutting speed (clips/min) | up to 720 | up to 600 |

| Stacking speed (stacks/min) | up to 160 | up to 300 |

| Linear speed (m/min) | 120 | 160 |

| Number of lines | up to 25 | over 24, up to 100 |

| Motor | Full servo | Full servo |

| Roll diameter (mm) std | opt | 1200 | 1500 | 1200 | 1500 |

| Roll width (mm) precut min | max | opt | 130 | 320 | 380 | 130 | 320 | 380 |

| Roll width semi-jumbo (mm) min | max | 800 | 1200 | 800 | 1200 |

| Stack length (mm) min | max | 100 | 300 | 100 | 300 |

| Folded wipe width (mm) min | max | 80 | 150 | 80 | 150 |

| Interfolding | Yes | No | Yes | No |

| Fold type | Z, C, W, modified V | Z, C, W, modified V |

| Reels splice std | opt | Manual | Automatic | Manual | Automatic |

| Clip height (mm) min | max | 5 | 25 | 25 | 80 |

| Stack height (mm) min | max | 5 | 80 | 25 | 80 |

| Count min | max | 5 | 120 | 25 | 120 |

| Quantity of lotion (%) min | max | 200 | 400 | 200 | 400 |

| Efficiency (%) precut rolls | semi-jumbo | > 90 | > 95 | > 90 | > 95 |

| Waste (%) | < 3 | < 3 |

FUTURA is a wet wipe folder extremely versatile, a reference for the whole market. It is totally configurable, matching any customer operation need for significant production volumes at reduced costs.

[buttons_on] => [cover_focus_buttons] => Array ( [buttons_on] => [view_default] => [buttons_items] => ) [focus] => Array ( [image] => 2651 [content] => FUTURA features from 12 up to 100 lanes ensuring a production speed up to 720 cuts/minute with any type of substrate, even the most delicate paper-based flushables or no-plastic nonwovens [buttons] => Array ( [buttons_on] => [view_default] => [buttons_items] => ) ) [body_class] => [no_follow] => [seo_image] => [seo_title] => [seo_description] => [versions_title] => IMA FACE 400D: Converting and packing solution for FFP2/3/N95 foldable respirators. [versions] => [versions_thumbnail] => 2374 [versions_tag_line] => IMA FACE 400D: Converting and packing solution for FFP2/3/N95 foldable respirators. [versions_overview] => [versions_overview_buttons] => Array ( [buttons_on] => [view_default] => [buttons_items] => ) [output_items_stripes] => )

Array

(

[rel_market] => Array

(

)

[clone_list] => Array

(

[0] => 7

)

[embed_iframe] =>

[form_price] =>

[contact] => eleonora.sarti@ima.it, sales@teknowebconverting.com

[no_index] =>

[thread_tag] =>

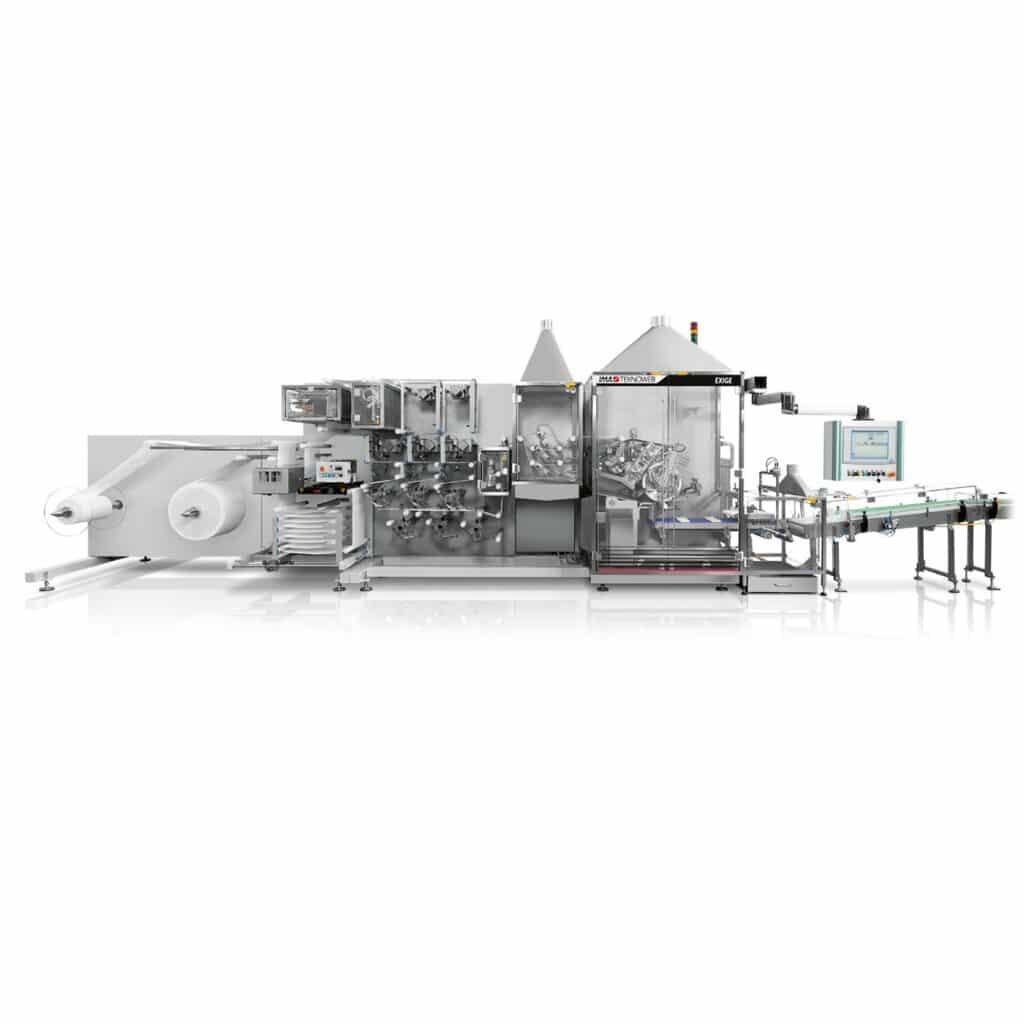

[tile_description] => EXIGE is a versatile production platform for cross-fold wipes; equipped with an accurate vacuum-less folding, EXIGE performs at high efficacy and low scrap in order to reduce TCO on any type of substrate.

[tile_speed] => Up to 200 packs/minute

[cover_macro] => 2193

[cover_name_type] => txt

[cover_name] => EXIGE

[cover_descriptor] => Wet wipe converting line

[cover_focus_on] => 1

[news] =>

[thumbnail] => 4686

[tag_line] => Fully automatic.

Fully performing.

[overview] => EXIGE is a versatile, reliable and high-speed production system for cross fold wipes that can reach up to 800 cuts per minute.

Available in 2, 3 or 4 lanes in single or double frame, it is fully automatic: from unwinder to wrapper feeding, needing just a few operators for correct functioning, also with no need from them to touch the product.

Equipped with an accurate vacuum-less folding, EXIGE performs at high efficacy and low scrap in order to reduce TCO on any type of substrate, even the most delicate paper-based flushable. Each machine process is adjustable with multiple parameters under the operator’s full control.

The totally configurable wetting system allows:

- one or more sanitary pumps with dedicated flowmeter, for perfect lotion dispensing on each wipe

- adjustable width or fixed width wetting bars, one per lane, to minimize lotion waste

- free choice of pre-fold wetting, post-fold wetting or both together, depending on substrate type

EXIGE can be provided compliant to ATEX (explosion proof) standards, to safely produce and handle wet wipes soaked in Isopropyl Alcohol (IPA) or any other flammable liquids.

It features an integrated quality control (Vision System), for non-conformities and to warn operators when cutting or tucking is not oprimal; this allows to reduce unplanned stops.

Pharma GMP (Good Manufacturing Practice) Standards compliant for materials, components and design, in order to minimize product contamination risks.

Process direction is straight without any 90° turns: this gives the machine a superior ergonomy and accessibility.

|

|

| The vacuum-less technology of Exige, allows a minimized lotion and liquids waste. | Exige can process raw materials with low (or even zero) environmental impact, compared to the standard wipes composed of PP, PE or viscose. The sustainable material handled by Exige is composed of cellulosic fibers derived from wood pulp. |

| EXIGE 2S | EXIGE 2 | EXIGE 3 | EXIGE 4 | |

| Design speed (wipes/min) | 1500 | 1800 | 2700 | 3600 |

| Operating speed (wipes/min) | 1200 | 1600 | 2400 | 3200 |

| Stacking speed (stacks/min) | 100 | 100 | 150 | 200 |

| Linear speed (m/min) | up to 120 | up to 160 | up to 160 | up to 160 |

| Number of lines | 2 | 2 | 3 | 4 |

| Drive | Full servo | Full servo | Full servo | Full servo |

| Stacker | Pneumatic cylinders | Linear motor | Linear motor | Linear motor |

| Roll diameter (mm) std | opt | 1200 | 1500 | 1200 | 1350 | 1200 | 1350 | 1200 | 1350 |

| Open wipe width (mm) min | max | 110 | 300 | 110 | 300 | 110 | 300 | 110 | 300 |

| Open wipe length (mm) min | max | opt | 150 | 200 | 150 | 200 | 150 | 200 | 300 | 150 | 200 |

| Folded wipe length (mm) min | max | opt | 75 | 100 | 75 | 100 | 75 | 100 | 200 | 75 | 100 |

| Interfolded | no | no | no | no |

| Fold type | Z, double Z | Z, double Z | Z, double Z | Z, double Z |

| Stack height (mm) min | max | 5 | 60 | 5 | 60 | 5 | 60 | 5 | 60 |

| Count min | max | 5 | 40 | 5 | 40 | 5 | 40 | 5 | 40 |

| Quantity of lotion(%) min | max | 200 | 300 | 200 | 300 | 200 | 300 | 200 | 300 |

| Efficiency (%) | > 95 | > 95 | > 95 | > 95 |

| Waste (%) | < 2 | < 2 | < 2 | < 2 |

Exige is a versatile production platform for cross-fold wipes, at a very high-speed, in compliance with the best sanitary standards and at a reduced Total Cost of Ownership (TCO).

[buttons_on] => [cover_focus_buttons] => Array ( [buttons_on] => [view_default] => [buttons_items] => ) [body_class] => [no_follow] => [seo_image] => [seo_title] => [seo_description] => [output_items_stripes] => )

Fully performing.

Array

(

[rel_market] => Array

(

)

[clone_list] => Array

(

)

[embed_iframe] =>

[form_price] =>

[contact] => eleonora.sarti@ima.it, sales@teknowebconverting.com

[no_index] =>

[thread_tag] =>

[tile_description] => GENESIS is a wet wipe converting line extremely reliable and effective, suitable for start-ups in the field, limited budget projects or for small lots productions but still demanding a high-quality finished product.

[tile_speed] => Up to 100 packs/minute

[cover_macro] => 2662

[cover_name_type] => txt

[cover_name] => GENESIS

[cover_descriptor] => Wet Wipe Converting Line

[cover_focus_on] => 1

[cover_focus_content] => GENESIS is a wet & dry wipe converting line extremely reliable and effective, suitable for start-ups in the field, limited budget projects or for small lots productions but still demanding a high-quality finished product.

[buttons_on] =>

[cover_focus_buttons] => Array

(

[buttons_on] =>

[view_default] =>

[buttons_items] =>

)

[news] =>

[thumbnail] => 4693

[tag_line] => The wipe converter for your needs.

[overview] => GENESIS is a length-fold wet & dry wipes converting line that can handle from 6 to 12 pre-cut rolls with manual or automatic splice for maximum flexibility and easiness of use.

In its “dry” version, it can produce wipes with standard fabrics, allowing the customer to produce a wide range of products on the very same line. For more specific fabrics the converter can be set up with dedicated features, to cope with raw material low basis weight and lack of adhesion between layers. These products include color catcher sheets or softeners sheets among the others.

Regarding the “wet” version, it comes complete of everything for a piece-of-mind project: sanitary lobe pump, electronic flowmeter, service tank with level sensors, CIP ready, equalizer pressing belt. Machine is also provided with high-speed and long lasting rotary die-cutter, with reliable blades in stainless steel that can cut up to 300mm length wipes.

GENESIS can be provided compliant to ATEX (explosion-proof) standards, to safely produce and handle wet wipes soaked in Isopropyl Alcohol (IPA) or any other flammable liquids.

It complies with the sanitary standards accepted worldwide, reducing risks of product contamination. All the equipment allow easy and effective CIP (Clean In Place) so that formula-change can be done quickly. This is the reason why Genesis is the preferred choice to produce small lots and with multiple changeover in a day.

It can include an integrated flow wrapper, tailored to perfectly match maker features and performance.

[overview_buttons] => Array

(

[buttons_on] =>

[view_default] =>

[buttons_items] =>

)

[sustainability] =>

[highlights_on] => 1

[focus_on] => 1

[versions_on] =>

[addon_on] =>

[output_on] => 1

[technical_data] => | GENESIS 10 | GENESIS 12 | |

| Design speed (wipes/min) | up to 6000 | up to 7200 |

| Operating speed (wipes/min) | up to 5000 | up to 6000 |

| Cutting speed (clips/min) | 500 | 500 |

| Stacking speed (stacks/min) | 120 | 120 |

| Linear speed (m/min) | 100 | 100 |

| Packing machine speed (packs/min) | 100 | 80 with gusset | 100 | 80 with gusset |

| Rolls – Precut | 10 | 12 |

| Drive System | Full Servo | Full Servo |

| Roll diameter (mm) std | opt | 1200 | 1500 | 1200 | 1500 |

| Roll width (mm) min | max | opt | 150 | 250 | 290 | 150 | 250 | 290 |

| Stack length (mm) min | max | 100 | 320 | 100 | 320 |

| Folded wipe width (mm) min | max | 75 | 120 | 75 | 120 |

| Interfolded | Yes | No | Yes | No |

| Fold type | Z, C, W, modified V | Z, C, W, modified V |

| Reels splice std | opt | Manual | Automatic | Manual | Automatic |

| Clip height (mm) min | max | 5 | 20 | 5 | 20 |

| Stack height (mm) min | max | 5 | 80 | 5 | 80 |

| Quantity of lotion (%) min | max | 200 | 350 | 200 | 350 |

| Labelling machines std | opt | 2 | 3 | 2 | 3 |

| Sealing of wrapping machine film | Automatic | Automatic |

| Sealing head | Long Dwell Technology | Long Dwell Technology |

| Waste (%) | < 3 | < 3 |