Quick access to IMA Sectors:

Pharma | Food & Dairy | Confectionery | Tea & Beverage | Coffee | Personal & Home Care | Tissue & Nonwoven | Automation | Tobacco | E-Commerce |VEGA 400

The pharmaceutical industry and safety regulators are placing more importance on external washers to remove product particles from the outside of containers after filling. Vega 400 complies with the present requirement and ensures complete decontamination.

The pharmaceutical industry and safety regulators are placing more importance on external washers to remove product particles from the outside of containers after filling. Vega 400 complies with the present requirement and ensures complete decontamination.

Pure performance, clean containers

Vega 400 is a rotary external washer designed to decontaminate the external surface

of ampoules and small glass vials after the filling and closing process.

The decontamination process can be carried out using water or by adding to the

water a dedicated washing media in case of toxic products, in order to avoid any

risk of contamination.

Vega 400 is the ideal solution for high-speed requirements and can be supplied in line

with filling and closing machines.

VEGA 400 Highlights

- Technical Data

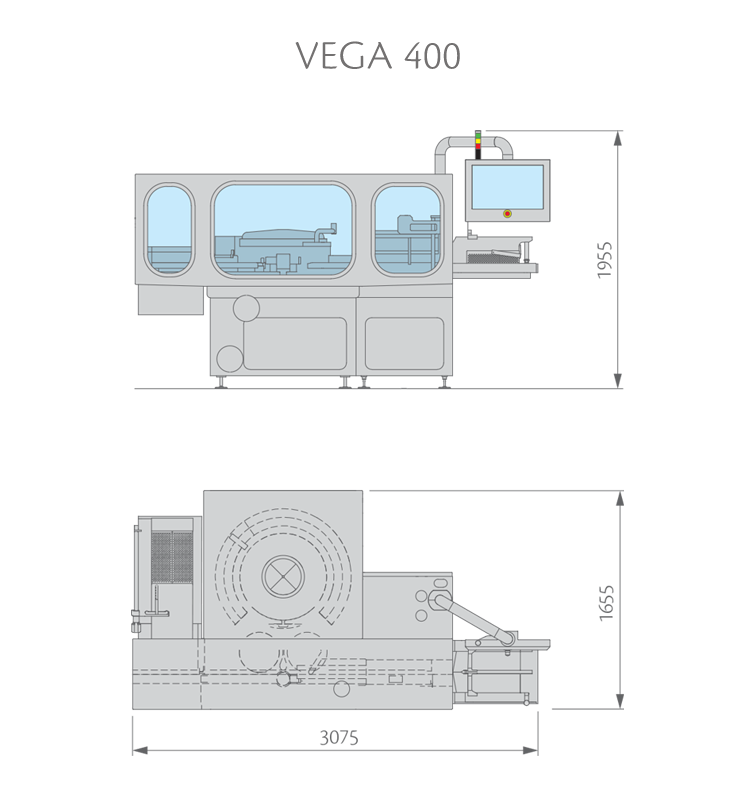

- Machine Layout

| TECHNICAL DATA – VEGA 400 | |

| Washing stations (Up to) | 7 |

| Maximum vial Ø (mm) | 52 |

| Maximum vial eight (mm) | 110 |

| Ampoule range Ø (mm) | 10-22.5 |

| Ampoule height (mm) | 35-110 |

| Output containers | 400 |

| Water consumptions (litres/hour) | 600-900 |

| Water pressure (bar) | 25-4 |

| Compressed air consumption (litres/minute) | 3100 |

| Compressed air pressure (bar) | 6 |

| Standard voltage | 400 V – 50 Hz |

| Installed power (kW) | 5 |

| Weight (kg) | 2700 |