Quick access to IMA Sectors:

Pharma | Food & Dairy | Confectionery | Tea & Beverage | Coffee | Personal & Home Care | Tissue & Nonwoven | Automation | Tobacco | E-Commerce |STICK

High technology applied in a very compact machine. STICK Series has been developed to ensure the highest productivity standards as no one in the market. These machines guarantee also high flexibility in terms of output and dosing sytems to meet any requirement

High technology applied in a very compact machine. STICK Series has been developed to ensure the highest productivity standards as no one in the market. These machines guarantee also high flexibility in terms of output and dosing sytems to meet any requirement

Maximum benefits with minimum space

STICK Series is available on different configurations depending on the product to pack: paste products, fluid products, powders, free and non free flowing products. It is possible to install double dosing systems for alternative productions and, in case of powder packaging, it is available a double auger to dose different powders into the same stick.

The stick sealing system is made up of a vertical sealing unit and a horizontal sealing unit. The vertical sealing unit can be opened in two ways (angular or rotating) allowing quick and easy access to the sealing bars and forming tubes. The horizontal sealing and pulling unit allows a rotating opening to easily access the sealing bar.

STICK machines assure extremely easy cleaning operations and size changeovers both in terms of length and width.

Optional checkweigher system available for 100% weight control and automatic feedback to the dosing system.

Sustainability

STICK machines are designed so that the production process involves minimal environmental impact:

- energy consumption is reduced to a minimum,

- the waste materials are minimized,

- compatibility with the use of recycled materials.

STICK Highlights

VERSIONS

STICK machines are available in different versions and configurations according to the output requested and the product characteristics.

Machine versions:

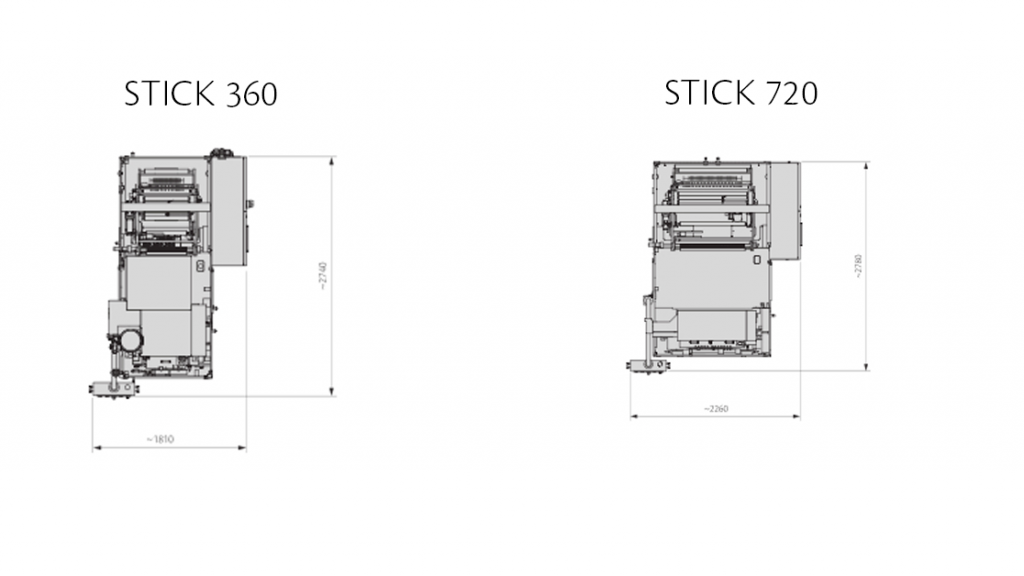

- STICK 360 for small and medium production and frequent changeovers

- STICK 720 for high production

Machine configurations:

- Configuration for dense and semi-dense products

- Configuration for powders, free and not free flowing products

- Configuration for fluid products

- Configuration for tablets and capsules

- Configuration for microtablets

Multiple dosing systems can be installed in the same machine, enabling alternative productions.

- Technical Data

- Machine Layout

| TECHNICAL DATA STICK 360 | |||

| Width (mm) | Length (mm) | N. Lanes | Production output |

| Possible format change | 60-160 | From 2 to 6 | Up to 420 sticks/min. |

| TECHNICAL DATA STICK 720 | |||

| Width (mm) | Length (mm) | N. Lanes | Production output |

| Pre-set fixed | 60 – 160 | From 2 to 12 | Up to 780 sticks/min. |