Quick access to IMA Sectors:

Pharma | Food & Dairy | Confectionery | Tea & Beverage | Coffee | Personal & Home Care | Tissue & Nonwoven | Automation | Tobacco | E-Commerce |SMART DB2

Sterile bags have many applications in the pharma market and IMA LIFE can provide high-speed turnkey solutions starting from the automatic loading and decontamination of the sterile empty bags up to their final collection.

Sterile bags have many applications in the pharma market and IMA LIFE can provide high-speed turnkey solutions starting from the automatic loading and decontamination of the sterile empty bags up to their final collection.

Multipurpose bag-filling made smart.

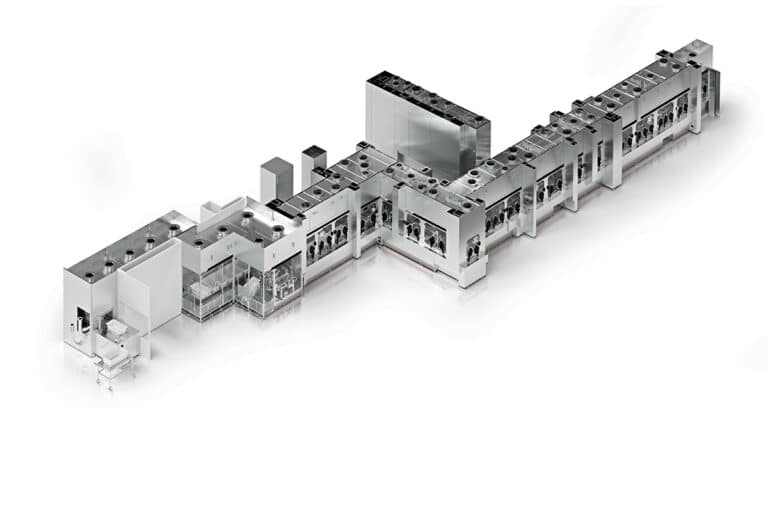

Working with flexible materials used in sterile bags does not contribute to making an aseptic filling process perfectly repeatable. Along the DB2 processing line, groups feature special technical solutions to overcome the non-repeatability issue, and Smart DB2 accomplishes the liquid and powder filling operations of the multi-chamber, Ready-To-Use sterile bags. The first filling process is made with powder drugs by means of dosing disks. The second filling process is made with liquid products, by means of mass-flow technology.

The integrated CIP SIP system allows cleaning and sterilisation-in-place procedures of both liquid and powder products, according to authority’s guidelines, minimising the need to remove and autoclave parts, and granting the SAL (Sterilisation Assurance Level).

SMART DB2 Highlights

- Technical Data

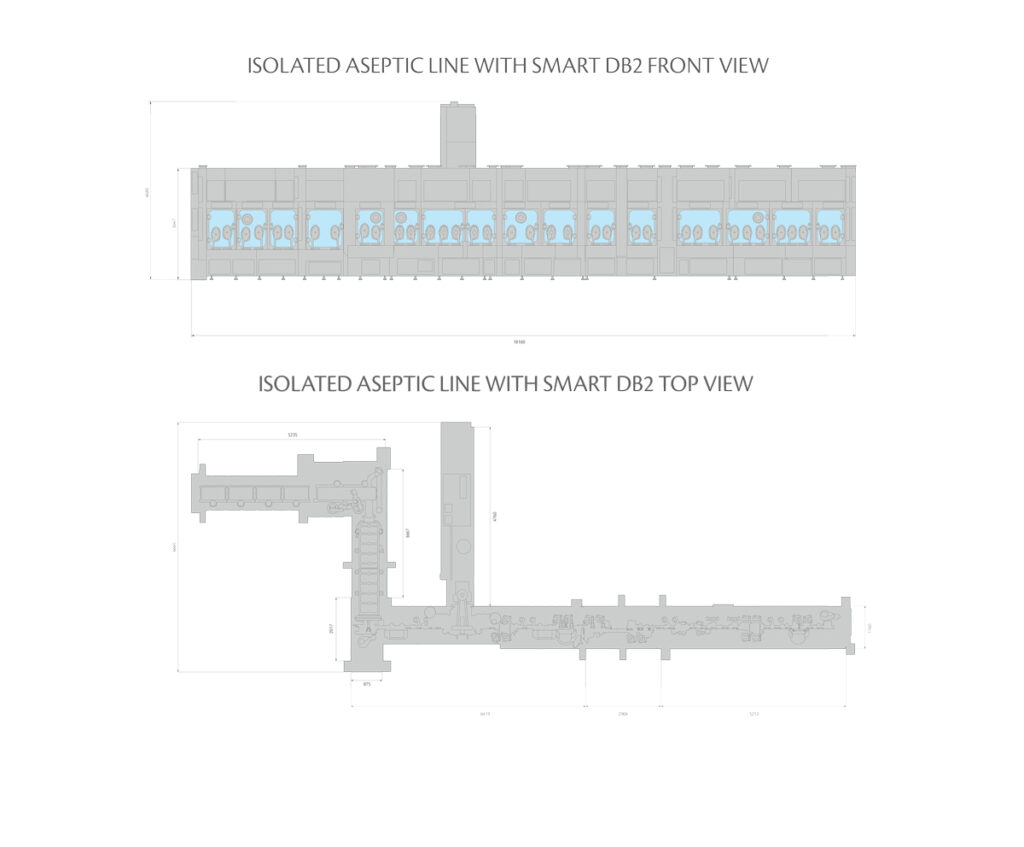

- Machine Layout

tbd