ROTO MIX is the latest generation high shear granulator. Inspired by the consolidated Roto technology existing in the pharmaceutical industry since the 1980s, ROTO MIX ensures the optimum shear for granulation at all speeds.

ROTO MIX is the latest generation high shear granulator. Inspired by the consolidated Roto technology existing in the pharmaceutical industry since the 1980s, ROTO MIX ensures the optimum shear for granulation at all speeds.

Granulation at its best.

ROTO MIX is a high shear mixer granulator designed for the dry mixing of powders and wet granulation. Mixing and agglomeration of powder particles is achieved by the combined action of impeller, chopper and liquid binder distributor. Available in a through-the-wall version, ROTO MIX optimises the room layout…

ROTO MIX Highlights

- Technical Data

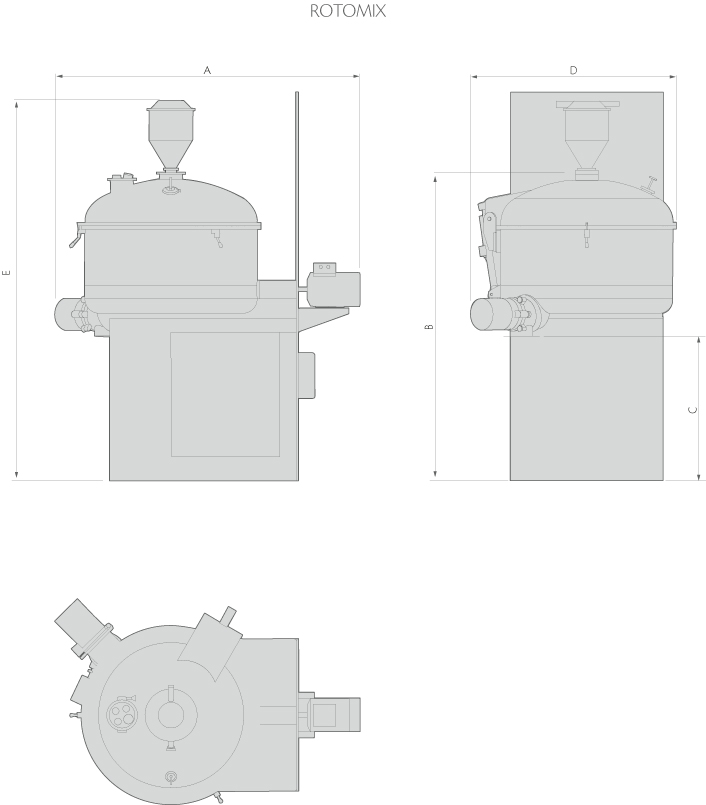

- Machine Layout

| TECHNICAL DATA ROTO MIX | ||||||||

| Model | 60 | 120 | 300 | 600 | 900 | 1200 | 1500 | 2500 |

| A (mm) | 1,380 | 1,720 | 2,180 | 2,430 | 2,620 | 2,750 | 2,850 | 3,500 |

| B (mm) | 1,520 | 1,620 | 2,000 | 2,400 | 2,650 | 2,700 | 2,830 | 3,020 |

| C (mm) | 870 | 1,060 | 1,240 | 1,300 | 1,340 | |||

| D (mm) | 850 | 1,050 | 1,315 | 1,500 | 1,700 | 1,800 | 1,900 | 2,240 |

| E (mm) | 2,120 | 2,220 | 2,600 | 3,070 | 3,320 | 3,370 | 3,490 | 3,890 |

| Bowl capacity (l) | 60 | 120 | 300 | 600 | 900 | 1,200 | 1,500 | 2,500 |

| Working capacity (l) | Minimum 25% – Maximum 70% | |||||||

| Impeller power (kW) | 4 | 11 | 18.5 | 30 | 45 | 55 | 75 | 115 |

| Impeller speed (rpm) | 15-275 | 15-220 | 10-165 | 10-130 | 10-115 | 10-100 | 10-97 | 6-82 |

| Chopper speed (rpm) | 700-1,450 (up to 2,000 with frequency converter) | |||||||

| Weight (kg) | 500 | 1,200 | 2,000 | 2,750 | 3,200 | 3,500 | 4,000 | 7,000 |