Quick access to IMA Sectors:

Pharma | Food & Dairy | Confectionery | Tea & Beverage | Coffee | Personal & Home Care | Tissue & Nonwoven | Automation | Tobacco | E-Commerce |RED250

The new integrated RED250 deep draw thermoforming and cartoning line is a compact solution for medium-speed production of small batches requiring frequent format changes.

The new integrated RED250 deep draw thermoforming and cartoning line is a compact solution for medium-speed production of small batches requiring frequent format changes.

Thanks to the robotic handling system, RED250 allows careful and precise manipulation of any type of product, introducing it into the tray with a wide range of possible configurations.

The new integrated A46 cartoning module can perform a complete automatic size changeover in just 10 minutes, allowing the operator to carry out the other operations necessary for the preparation of the next batch.

In the face of increasingly demanding production needs, the new line represents an agile solution ensuring precision and performance.

Sustainability

Bio-degradable tray Project

IMA offers a complete range of deep thermoforming machines from low to high speed.

All of them are designed with the environment in mind. Our well established technologies have been thought once again for the best handling of new generation materials such as the bio-degradable PLA. We keep the same performance, the same quality, with a new purposes: our Planet.

Applicable to No one is forgotten: new applications are suitable for retrofitting on existing C260, C360 and C102 with just small adjustments in the forming area.

RED250 Highlights

- Technical Data

- Machine Layout

| MAX PRODUCTION OUTPUT | |||||

| TRAYS | CARTONS | FORMING DEPTH | LIDDING MATERIALS | LIDDING MATERIALS | CARTON DIMENSION |

|

800 1-2 ml DIN 400 1 ml DIN syringe/min |

250 ctn/min | 3 mm – 40 mm | ALU, PP, PVC, PVC/PVDC, PVC/ACLAR®, PET, PETG, PS and others | ALU-HARD, ALU-SOFT, ALU/PAPER, ALU/ POLYESTER, PP, TYVEK® and others |

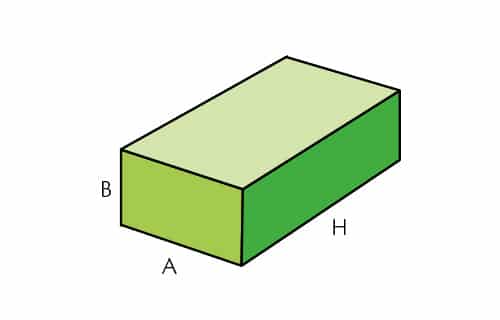

A: 35-95 |