Simple, reliable and effective, PRACTICA is the unbeatable answer to a wide variety of straightforward capsule filling requirements. A competitive solution in terms of speed, precision and ease of use.

Simple, reliable and effective, PRACTICA is the unbeatable answer to a wide variety of straightforward capsule filling requirements. A competitive solution in terms of speed, precision and ease of use.

Engineered simplicity is hard to beat.

A combination of IMA Active’s technological expertise and understanding of industry requirements, PRACTICA guarantees high reliability in processing granules, powder or pellets.

PRACTICA Highlights

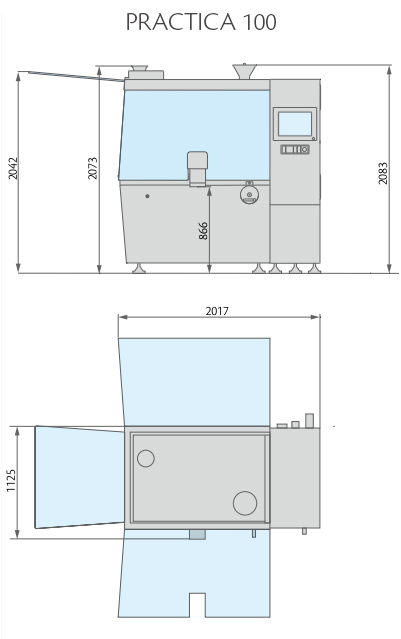

PRACTICA 100

The PRACTICA 100 capsule filler can reach a speed of 100,00 capsules/hour and performs single product dosing (powder/granulate or pellets) with very high accuracy.

The machine is prearranged to be equipped with a statistic weight checking unit for production monitoring, that combined with self-adjustment allows to automatically keep the production within the parameters set by the operator.

PRACTICA 200

The PRACTICA 200 capsule filler can reach a speed of 200,00 capsules/hour and performs single product dosing (powder/granulate or pellets) with very high accuracy.

The machine is prearranged to be equipped with a statistic weight checking unit for production monitoring, that combined with self-adjustment allows to automatically keep the production within the parameters set by the operator.

- Technical Data

- Machine Layout

| TECHNICAL DATA PRACTICA | ||

| MODEL | PRACTICA 100 | PRACTICA 200 |

| Maximum output (capsules/hour) | 100,000 | 200,000 |

| Number of capsules per cycle | 12 | 24 |

| Capsule size | 5-00EL, 000, DB | 5-00EL, 000, DB |

| Maximum installed power (kW) | 15 | 16 |

| Aspiration | 5,100 litres/minute – 3,200 mm H2O | 9,500 litres/minute – 3,200 mm H2O |

| Compressed air | 115 litres/minute – 6 bar | 115 litres/minute – 6 bar |

| Vacuum | 100 m³/h – 3 mbar (abs.) | 100 m³/h – 6 mbar (abs.) |

| Standard voltage | 400 V – 50 Hz | 400 V – 50 Hz |

| Weight (kg) | 1,900 | 2,300 |