menu

Request for quotation

This is Pharma Website

Quick access to IMA Sectors:

Pharma | Food & Dairy | Confectionery | Tea & Beverage | Coffee | Personal & Home Care | Tissue & Nonwoven | Automation | Tobacco | E-Commerce |

Pharma Website

Choose the market

blur_on

MYLAB

Granulation and coating equipment

MYLAB is an essential tool to select the most appropriate technology for your products. Must-have equipment also for formulation and scale-up studies to easily achieve production requirements.

MYLAB is an essential tool to select the most appropriate technology for your products. Must-have equipment also for formulation and scale-up studies to easily achieve production requirements.

Made easy for you.

MYLAB is a compact and modular R&D unit for the granulation and coating process. It consists of a Main Technical Unit with a fully integrated air-handling unit, spray system and control panel. Designed to process small batches, accurate scale-up is assured from this easy-to-use laboratory suite.

settings_applications

Production Plant

IMA Active

MYLAB Highlights

1.

Control panel integrated in the MTU and prearranged to work with both production modules.

2.

MAX new corporate HMI plays a strategic role in improving operator efficiency, while ensuring prompt responsiveness, enhanced predictability and easy learning.

3.

Fluid bed module with interchangeable product containers for top and bottom spray processes: batches from 3 to 6 litres.

4.

Fuid bed module with high shear mixer available for dry mixing and wet granulation processes.

5.

Coating pan equipped with an interchangeable drums in: fully perforated and/or Wedge and/or Solid wall executions suitable for batches from 0.5 to 10 litres.

6.

Coating pan equipped with welded wave-shaped baffles for optimal mixing of the cores.

Compliant to the most restrictive GMP rules and highly ergonomic, MYLAB allows quick and easy product change. A unique combination in terms of flexibility, accuracy and configuration.

- Technical Data

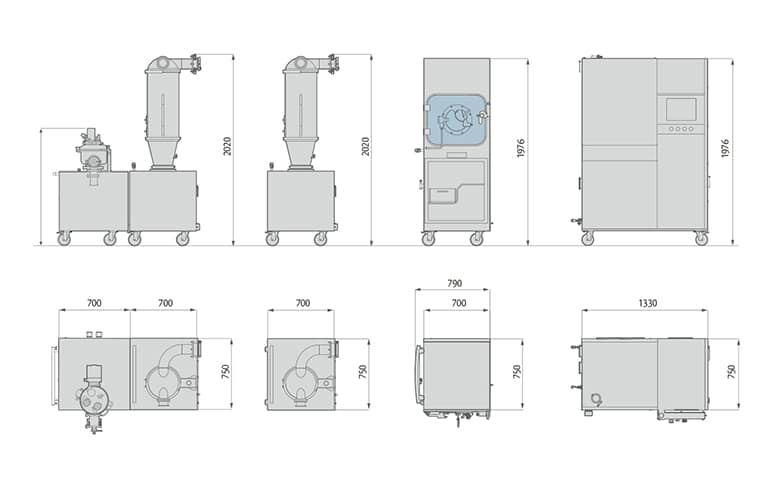

- Machine Layout

| TECHNICAL DATA MYLAB | ||

| MODULAR TECHNICAL UNIT (MTU) | ||

| Air flow (Nm³/h) | 50 – 300 | |

| Air temperature (°C) | 20 – 90 | |

| FLUID BED MODULE INTERCHANGEABLE BOWLS | ||

| Min/max capacity (litres) | ||

| Top Spray bowl (8 litres) | 3 – 6 | |

| Top Spray bowl (4 litres) | 1-3 | |

| Bottom Spray bowl (8 litres) | 3 – 6 | |

| FLUID BED MODULE WITH HIGH SHEAR GRANULATOR INTERCHANGEABLE BOWLS | ||

| Min/max capacity (litres) | ||

| HSG bowl (7 litres) | 2-5 | |

| HSG bowl (3 litres) | 0.75-2 | |

| COATING PAN MODULE INTERCHANGEABLE DRUMS | ||

| Min/Max capacity (litres) | Pan diameter (mm) | |

| Perforated drum (6 litres) | 1.5-6 | 460 |

| Perforated drum (2 litres) |

0.5-2 |

420 |

| Perforated drum (10 litres) | 2.5-10 | 490 |

| Solid wall drum | 1-3 | 455 |

| Edge wired drum | 0.6-6 | 460 |

markunread

Contact us