Quick access to IMA Sectors:

Pharma | Food & Dairy | Confectionery | Tea & Beverage | Coffee | Personal & Home Care | Tissue & Nonwoven | Automation | Tobacco | E-Commerce |INJECTA 36

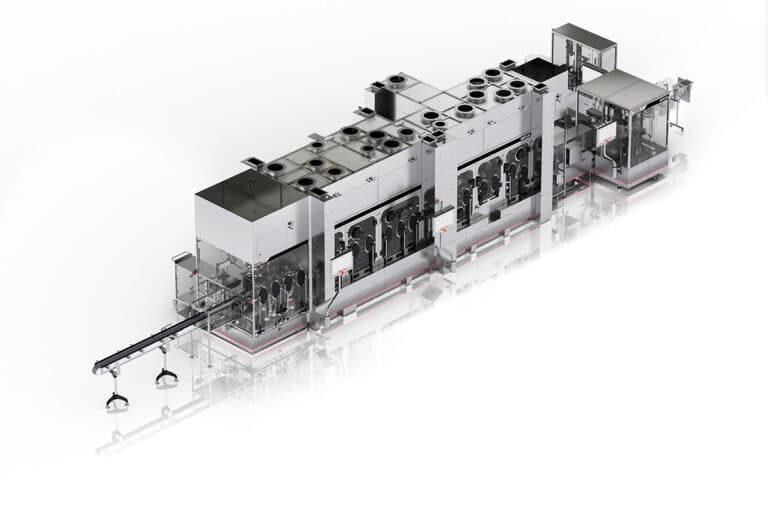

INJECTA 36 is a fine-tuned solution to enhance aseptic fill-finish capabilities and maximise processing line performance. Handling up to 36,000 RTU components per hour, in particular syringes, the system adopts innovative robotic and automation technologies.

INJECTA 36 is a fine-tuned solution to enhance aseptic fill-finish capabilities and maximise processing line performance. Handling up to 36,000 RTU components per hour, in particular syringes, the system adopts innovative robotic and automation technologies.

INJECTA 36. Single detection, single rejection.

The use of advanced robotic-driven manipulations versus conventional handling systems actually improves product quality and manufacturing efficiency.

INJECTA 36 handles pre-sterilised Ready-To-Use containers (syringes, vials or pre-capped cartridges) pre-arranged in tubs, allowing high process flexibility and adaptability.

Specialised robots perform all handling activities with no glass-to glass contact and without operator intervention. The result is “less time” spent validating aseptic conditions and superior agility for multi-product manufacturing.

The highest accuracy and safety in plunger presence detection and single non-conformity rejection are ensured by DETECTA, IMA Life’s ultimate high-speed inspection unit, which can be integrated downstream of INJECTA 36.

INJECTA 36 Highlights

- Technical Data

- Machine Layout

| FEATURES | INJECTA FAMILY | ||

| INJECTA 36 | INJECTA 10 | INJECTA 6 | |

| Automation | Fully robotic automated | Fully robotic automated | Fully robotic automated |

| Footprint (mm) | 3,400 x 2,050 x 2,080 [L x W x H] | 7,200 x 4,500 x 2,080 [L x W x H] | 6,100 x 3,600 x 2,080 [L x W x H] |

| In-Process Control | 100% | 100% at full speed | 100% at full speed |

| RTU vial dimensions | Ø 16 – 42.4 mm | Ø 16 – 42.4 mm | Ø 16 – 42.4 mm |

| Vial output | up to 18,000 pcs/h | up to 12,000 pcs/h | up to 4,800 pcs/h |

| RTU syringe dimensions | 0.5 – 20 ml | 0.5 – 50 ml | 0.5 – 50 ml |

| Syringe output | up to 36,000 pcs/h | up to 12,000 pcs/h | up to 4,000 pcs/h |

| RTU cartridge dimensions | 1 – 20 ml | 1 – 20 ml | 1 – 20 ml |

| Cartridge output | up to 18,000 pcs/h | up to 10,800 pcs/h | up to 3,600 pcs/h |

| Suitable for high-potent | Yes | Yes | Yes |

| Loading from depyrogenation tunnel | No | Yes | Yes |