Quick access to IMA Sectors:

Pharma | Food & Dairy | Confectionery | Tea & Beverage | Coffee | Personal & Home Care | Tissue & Nonwoven | Automation | Tobacco | E-Commerce |CPV15

A medium-output, top loading case packer for loose or bundled products, the CPV15 has been conceived to assure maximum ergonomics for operating staff and guarantee smooth handling even for unusually shaped products thanks to servo technology.

A medium-output, top loading case packer for loose or bundled products, the CPV15 has been conceived to assure maximum ergonomics for operating staff and guarantee smooth handling even for unusually shaped products thanks to servo technology.

Products case packed to perfection.

Maximum attention to ergonomics is a hallmark of this case packer.

In order to be as operator-friendly as possible, the case erecting mechanism is designed to ensure low positioning of the horizontal case magazine, which also ensures increased autonomy. Machine parts can be reached without operators needing to move from one side of the machine to the other.

The infeed system is equipped with worm screws (for loose products) for the correct orientation of the containers and a comb which moves sideways to collate the products.

Equipped as standard, the CPV15 features a 2-axis robot to insert the collation into the case.

CPV15 Highlights

Case Packer - Palletizer integrated versions

The CPV15 is available as a stand alone machine or in different palletizer-integrated versions, according to the output required:

CPV15-RP2

With automatic replacement of the full pallet and case buffering during pallet replacement or with two pallet stations; once one pallet is complete, the robot starts loading the second pallet

CPV15-RP4

With 4 pallet stations for greater autonomy. When the pallet is complete, the automatic transport moves the pallet to the exit area and replaces it with an empty one.

- Technical Data

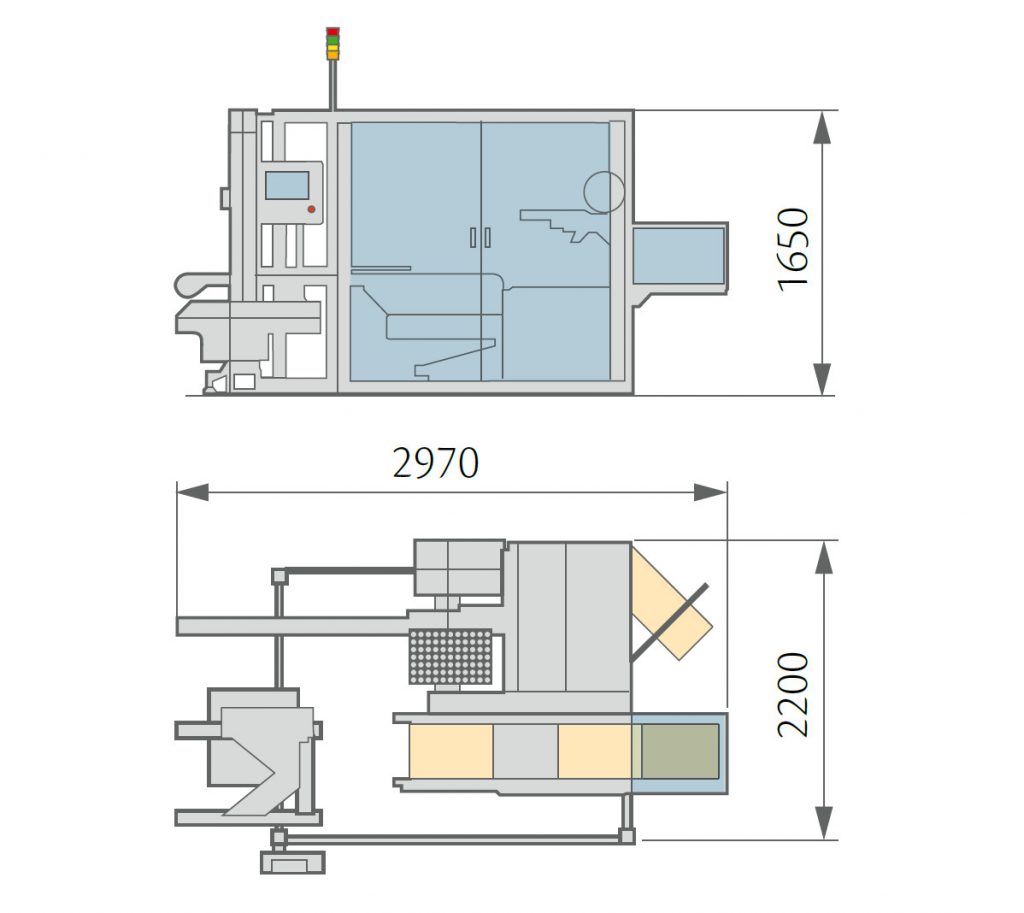

- Machine Layout

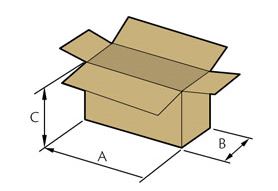

| TECHNICAL DATA CPV15 | ||||||||

| Product dimensions | A | B | C | |||||

| CPV15 | Min. | 190 | 80 | 100 | ||||

| Max | 600 | 400 | 350 | |||||

| Max. speed | 15 | |||||||