menu

This is Pharma Website

Quick access to IMA Sectors:

Pharma | Food & Dairy | Confectionery | Tea & Beverage | Coffee | Personal & Home Care | Tissue & Nonwoven | Automation | Tobacco | E-Commerce |

Pharma Website

Choose the market

blur_on

C945

Automatic tubefiller

The modular concept design allows this Comadis model to grow up together with customer needs: a lighter early configuration can be completed –in the future– with automatic tube loader, print registration device and many other ancillary equipments.

The modular concept design allows this Comadis model to grow up together with customer needs: a lighter early configuration can be completed –in the future– with automatic tube loader, print registration device and many other ancillary equipments.

The only automatic tubefiller on the market with offline filling capability

Great in performances – despite of its compact dimensions – Co.Ma.Di.S. C945 can be run in totally automatic mode, as well as a pedal-controlled filler for jars and small containers, thanks to dosing pump that can be rotated outwards.

settings_applications

Production Plant

Co.Ma.Di.S. S.P.A.

C945 Highlights

1.

Manual or automatic tube feeding.

2.

Dosing pump easy to reposition outside machine footprint, pedal controlled.

3.

Customized “designer seals” on request.

4.

Quick interchangeability of closing heads.

5.

Simplified and easy change of size parts, without tools.

6.

Compact operator panel (HMI), suitable to memorize working parameters.

7.

Special executions available.

The smallest tubefiller on the market, marked by outstanding flexibility. Dosing pump is easy to reposition outside footprint for manual filling; interchangeable closing heads perform any type of metal tube folding and a variety of plastic tube sealing shapes.

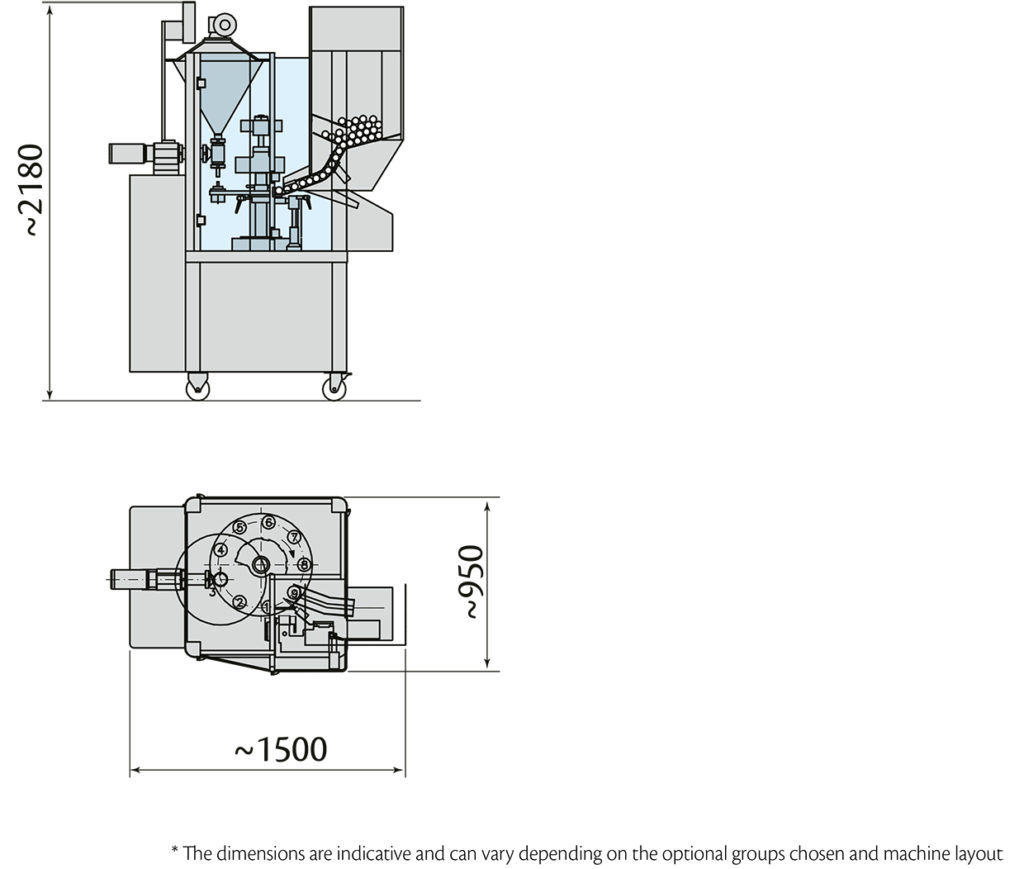

- Technical Data

- Machine Layout

| TECHNICAL DATA C945 | |

| Mechanical speed | Up to 45 tubes/min. |

| Filling volume | 2-300 mL (on request up to 500 mL) |

| Tube diameter | 10-50 mm (on request polythene and aluminium tubes up to 60 mm) |

| Tube length | 60-250 mm |

| Working stations | 9 |

markunread

Contact us