Quick access to IMA Sectors:

Pharma | Food & Dairy | Confectionery | Tea & Beverage | Coffee | Personal & Home Care | Tissue & Nonwoven | Automation | Tobacco | E-Commerce |C1290/C12110

Available in different levels of automation along with the widest range of additional devices, to grant the “state of the art” of single nozzle technology. Performance is combined to simplicity in change-over sequences and quick dismantling of contact parts.

Available in different levels of automation along with the widest range of additional devices, to grant the “state of the art” of single nozzle technology. Performance is combined to simplicity in change-over sequences and quick dismantling of contact parts.

Complete, fast, easy to use: Comadis C1290 is the ultimate proposal coming from many years experience in tube filling industry

Co.Ma.Di.S. C1290 is a major update of the successful “C1090”, the benchmark model sold worldwide in many different applications, which has proved to offer enough flexibility to be used in various configurations.

Improved in a number of details, it is now performing tube cleaning by dedicated station, batch data collection via USB port and continuous monitoring – on request – of tube folding and tube crimping areas.

Sustainability

|

| This system is able to handle sustainable plastic materials. |

C1290/C12110 Highlights

C1270S FOR HIGH VISCOSITY PRODUCTS

SPECIAL APPLICATIONS

- Technical Data

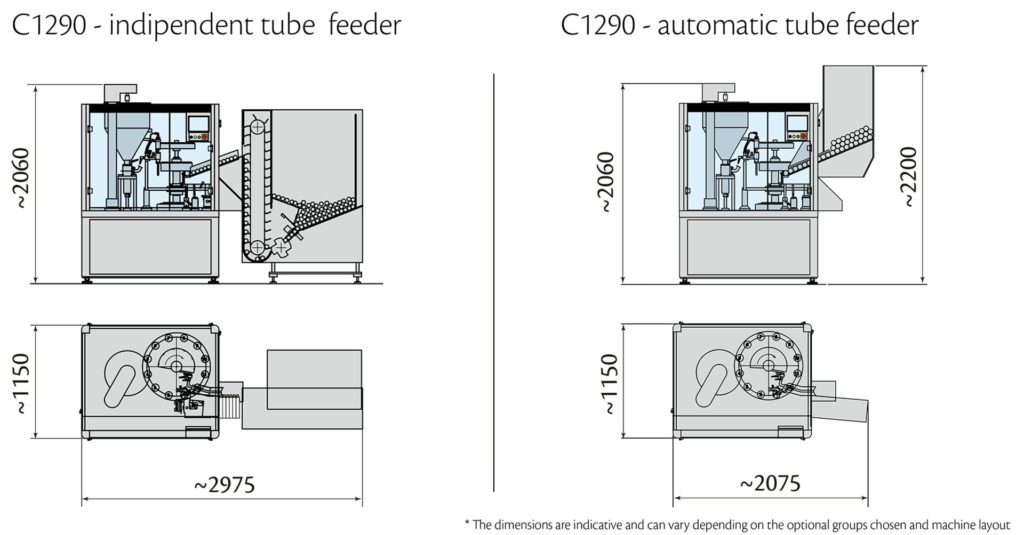

- Machine Layout

| TECHNICAL DATA C1290/C12110 | |

| Mechanical speed | Up to 90 tubes/min. (C1290) |

| Up to 110 tubes/min. (C12110) | |

| Filling volume | 2-250 mL (on request up to 350 mL) |

| Tube diameter | 10-50 mm (on request polythene and aluminium tubes up to 60 mm) |

| Tube length | 60-250 mm |

| Working stations | 12 |