Quick access to IMA Sectors:

Pharma | Food & Dairy | Confectionery | Tea & Beverage | Coffee | Personal & Home Care | Tissue & Nonwoven | Automation | Tobacco | E-Commerce |OPEN RABS

Open RABS represent the first solution available in the barrier technology scenario, introducing the concept of product protection in a GMP grade facility for sterile products.

Open RABS represent the first solution available in the barrier technology scenario, introducing the concept of product protection in a GMP grade facility for sterile products.

Ensuring safe operating conditions, by design.

Open Restricted Access Barrier Systems (Open-RABS or O-RABS) are a simple and widely adopted solution in the pharmaceutical sector to separate the production area from operators and the cleanroom environment. They maintain Grade A (ISO 5) conditions within the critical zone, supported by unidirectional airflow, while operating in a surrounding Grade B environment, in line with EU GMP Annex 1.

Although considered the “minimum barrier” for aseptic processing, Open RABS are compliant with regulatory expectations when properly designed, validated, and integrated with robust procedures. Cleaning and decontamination can be effectively managed through controlled access, manual interventions with appropriate disinfectants, and routine decontamination achievable with cleanroom VPHP cycle integration (if available), ensuring both surface cleanliness and microbial control.

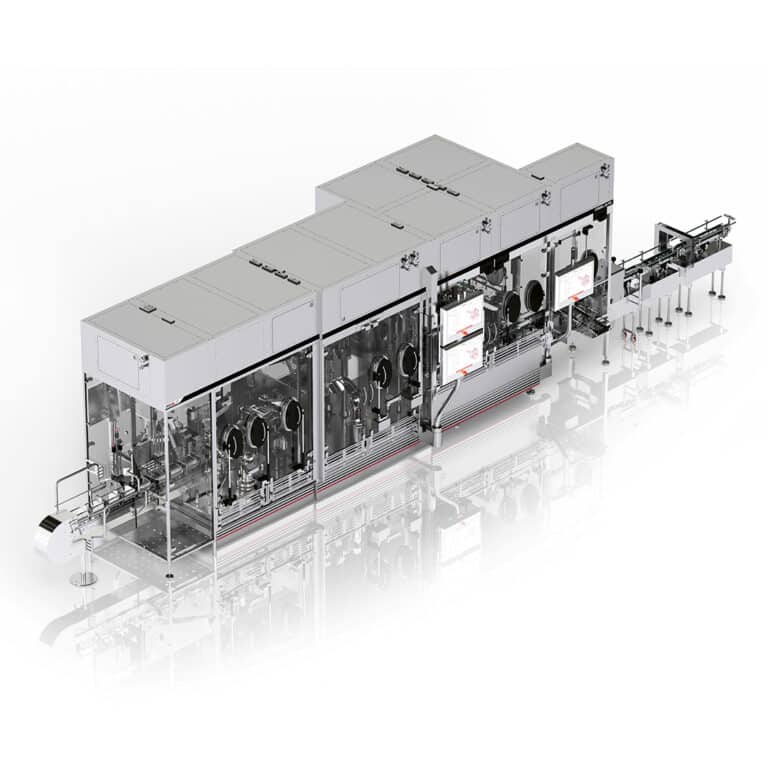

Their modular and simple design makes them easy to install on aseptic filling lines, offering a cost-efficient upgrade without major facility modifications. However, since the barrier is not fully closed, their use is less suitable for potent substances or biohazardous products, where Closed RABS or isolators provide higher levels of protection.

Sustainability

IMA has always been committed to reducing the environmental impact of its equipment, addressing the issue of consumption through design choices, high-efficiency components and optimising the control dynamics on processing machines such as barrier technologies (open RABS and closed RABS).

OPEN RABS Highlights

- Machine Layout