menu

This is Pharma Website

Quick access to IMA Sectors:

Pharma | Food & Dairy | Confectionery | Tea & Beverage | Coffee | Personal & Home Care | Tissue & Nonwoven | Automation | Tobacco | E-Commerce |

Pharma Website

Choose the market

blur_on

GS EVOLUTION

Coating pan

Designed for highly automated installations, GS EVOLUTION represents the ideal base for a contained plant. The machine reduces operator exposure in case of the processing of high potent products.

Designed for highly automated installations, GS EVOLUTION represents the ideal base for a contained plant. The machine reduces operator exposure in case of the processing of high potent products.

Coating (r)evolution.

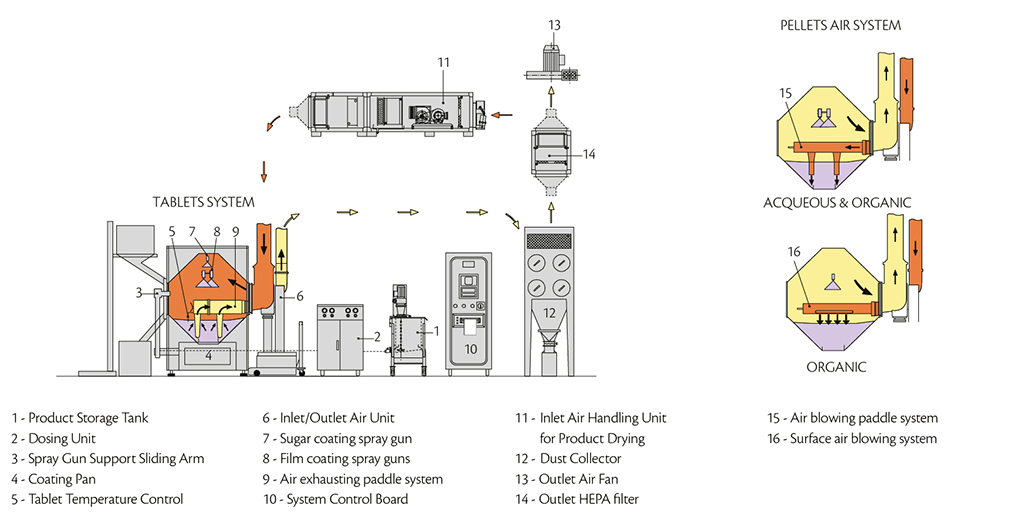

GS EVOLUTION is a highly automated solid wall pan for tablet film and sugar coating, which also produces pellets and microgranules via powder layering. The machine can be supplied with different levels of automation depending on the customer’s requirements.

settings_applications

Production Plant

IMA Active

GS EVOLUTION Highlights

1.

Perfect mixing and uniform distribution of coating material thanks to the shape of the pan and surface smoothness.

2.

Patented drying system.

3.

Different paddle sizes for higher flexibility in terms of pan working capacities.

4.

Two pan types available: standard or spiralled for automatic product and water discharge.

5.

Complete isolation of the processing area by means of inflatable seals on front and rear doors.

The automatic and easy-to-validate cleaning cycle can start immediately after production without the installation of any additional device. Water can be discharged through the hole placed in the pan bottom or through the high efficiency discharging spiral.

- Technical Data

- Machine Layout

| TECHNICAL DATA GS EVOLUTION | |||||||

| Model | GS 30*** | GS 70 | GS 150 | GS 300 | GS 450 | GS 600 | GS 800 |

| Minimum/maximum working capacity (l)* | 0.5÷30 | 40÷70 | 70÷150 | 150÷300 | 200÷450 | 350÷650 | 450÷850 |

| Pan diameter (mm) | 820 | 1,050 | 1,280 | 1,580 | 1,630 | 2,000 | 2,200 |

| Pan mouth diameter (mm) | 300 | 400 | 450 | 520 | 730 | ||

| Pan motor power (kW) | 0.55 | 1.1 | 1.5 | 3 | 4 | 5.5 | 7.5 |

| Process air delivery (m³/h) | 350 | 1,000 | 1,400 | 2,500 | 3,000 | 4,000 | 5,000 |

| Power consumption for standard equipment (kW)** | 14 | 10 | 12 | 20 | 25 | 30 | 35 |

| * Approximate data (depending on core shape and specific weight) | |||||||

| ** Approximate data (depending on equipment configuration) | |||||||

| *** Interchangeable drum | |||||||

markunread

Contact us