Quick access to IMA Sectors:

Pharma | Food & Dairy | Confectionery | Tea & Beverage | Coffee | Personal & Home Care | Tissue & Nonwoven | Automation | Tobacco | E-Commerce |PERFIMA

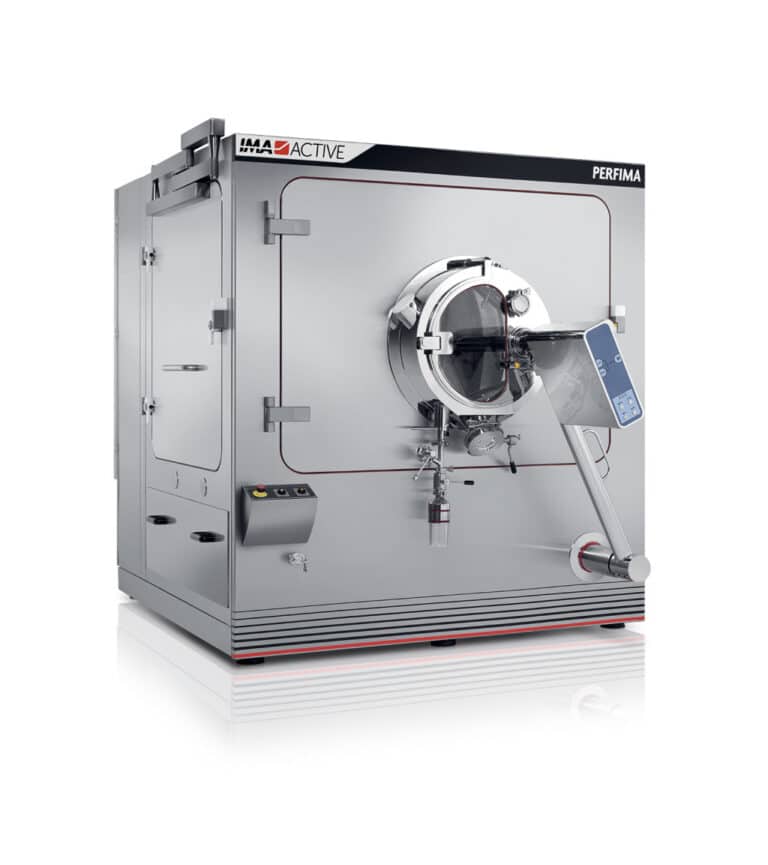

Conceived to provide the highest efficiency in the field of automatic coating equipment, PERFIMA guarantees remarkable performance with all processes. Also suitable for containment installations, the machine reduces operator exposure while working with HAPI.

Conceived to provide the highest efficiency in the field of automatic coating equipment, PERFIMA guarantees remarkable performance with all processes. Also suitable for containment installations, the machine reduces operator exposure while working with HAPI.

Advanced coating.

PERFIMA is a perforated coating pan for tablet film and sugar coating. The shape of the pan combined with the mixing baffles positioned in the central sector of the drum ensure perfect mixing of the cores allowing a wide range of batches to be processed in the same drum: from 25% to 100% of pan capacity.

Sustainability

A large number of pharma companies are looking into energy consumption optimisation by using reduction and recovery strategies, while the innovations in washing technology can improve water consumption throughout the various steps of the cleaning cycle.

PERFIMA water recirculation system allows consumption saving and reduces the disposal of dirty water at the end of the washing cycle, while granting optimal equipment performance. The AHU allows energy efficiency thanks to the recovery of treated air which is used to cool/heat the incoming air thus maintaining optimal system performance.

PERFIMA Highlights

Lab Versions

Equipped with welded mixing baffles for tablet film and sugar coating.

PERFIMA ECHO ensures a perfect and uniform mixing of the cores thanks to the shape of the pan combined with the mixing baffles positioning on the central sector of the drum. The mixing capability is maintained in case of minimum or maximum quantity of product, allowing a wide range of batches to be processed in the same machine (from 25% to 100% of the pan capacity).

Equipped with removable mixing baffles for tablet film and sugar coating.

PERFIMA EXTRA has been specifically designed to increase the machine flexibility in terms of workable products and range of batches to be processed. The shape of the drum guarantees the uniform mixing of the product, while the removable mixing baffles allow different machines configurations ensuring a wider range of batches that can be processed in the same pan (from 10% to 100% of the pan capacity).

Equipped with wedge wire screen for pellet, minitablet and tablet processing.

The unique design of PERFIMA EDGE wedge wire screen drum provides a suitable surface, guaranteeing gentle treatment of the cores during coating. On the external surface of the drum, the wedge wires provide a semi-conical shape guaranteeing easy removal of the suspension coating residual and an efficient cleaning.

- Technical Data

| TECHNICAL DATA PERFIMA | ||||||

| Model | LAB* | 200 (120) | 200 | 500 (360) | 500 |

800 |

| Minimum/maximum capacity (litres) |

6 (1.5 – 6) |

30-120 |

60-250 |

90-360 |

140-550 |

240-950 |

| Pan diameter (mm) |

715 (for 6 L drum) |

1,200 | 1,360 | 1,516 | 1,716 | 1,985 |

| Pan mouth diameter (mm) | 474 | 540 | 540 | 580 | 580 | 732 |

| Pan motor power (kW) | 1.5 | 4 | 4 | 5.5 | 5.5 | 7.5 |

| Process air delivery (m³/h) | 1,100 | 2,500 | 4,000 | 5,000 | 6,000 | 8,000 |

| * Interchangeable drum | ||||||

| ** Available with removable baffles in Extra drum | ||||||