menu

This is Pharma Website

Quick access to IMA Sectors:

Pharma | Food & Dairy | Confectionery | Tea & Beverage | Coffee | Personal & Home Care | Tissue & Nonwoven | Automation | Tobacco | E-Commerce |

Pharma Website

Choose the market

blur_on

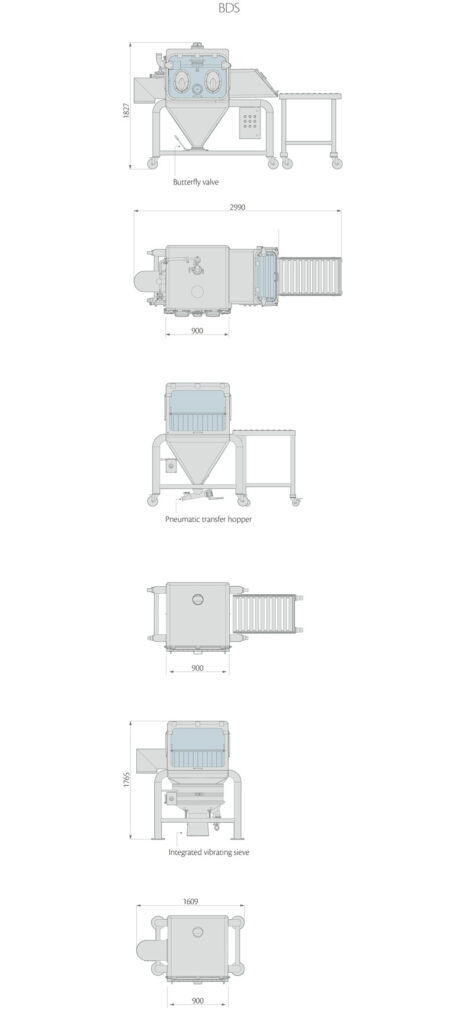

BDS

Bag dumping station

Simple design, reduced dimensions, accurate finishing. These key features make BDS a versatile accessory for the optimisation of powder and granules handling in the pharmaceutical industry.

Simple design, reduced dimensions, accurate finishing. These key features make BDS a versatile accessory for the optimisation of powder and granules handling in the pharmaceutical industry.

Safety in containment.

The BDS Bag Dumping Station for powders or granules is designed for discharging bags and small containers in contained conditions, reducing the contamination level of the working environment.

Thanks to its front port and bottom outlet in dust-tight conditions, BDS can be easily integrated with the loading and unloading devices of the Pharma Handling Systems.

settings_applications

Production Plant

IMA Active

BDS Highlights

1.

Internal parts manufactured in AISI 316 stainless steel, mirror polished.

2.

Easy cleaning thanks to smooth finishing without dead corners.

3.

Large front opening to enable perfect accessibility during loading operations.

4.

Clamped connection provided to the bottom outlet for installation of a butterfly valve or a pneumatic transfer hopper.

- Technical Data

- Machine Layout

| TECHNICAL DATA BDS | |

| Vacuum | 50 m³/h – 20 mbar |

| Maximum installed power (kW) | 1 |

| Standard voltage | 400 V – 50 Hz |

| Water consumption | 26 litres/minute – 3 bar |

| Tools compressed air | 600 Nl/min – 5 barg |

markunread

Contact us