Quick access to IMA Sectors:

Pharma | Food & Dairy | Confectionery | Tea & Beverage | Coffee | Personal & Home Care | Tissue & Nonwoven | Automation | Tobacco | E-Commerce |ADAPTA 7-21-50

ADAPTA synthesizes all the best of IMA Active competences in capsule filling. Available in multiple configurations, the machine is unique on the market and further underscores the hallmarks of the acknowledged ADAPTA capsule fillers.

ADAPTA synthesizes all the best of IMA Active competences in capsule filling. Available in multiple configurations, the machine is unique on the market and further underscores the hallmarks of the acknowledged ADAPTA capsule fillers.

More than a machine.

ADAPTA 50 features innovative technical solutions to manage complex solid dosage forms such as product combination in hard gelatine capsules or powder micro-dosing for Dry Powder Inhalers. The machine is available in multiple configurations, including the ADAPTA 7 and ADAPTA 21 versions, reaching speeds of 7,000 and 21,000 capsules per hour, respectively.

Sustainability

The use of advanced sensors together with evaluation algorithms of produced data, allow full control of production, setting the premises for Advanced Control Strategies. Advanced machine learning functions are used for more efficient self-adjustment of process parameters: less waste, better product quality. All this maximises machine functionality, keeping the machine performance on target and allowing the single rejection of products out of specification. ADAPTA no-fill bypass prevents product waste if the capsule body is not present.

ADAPTA 7-21-50 Highlights

- Technical Data

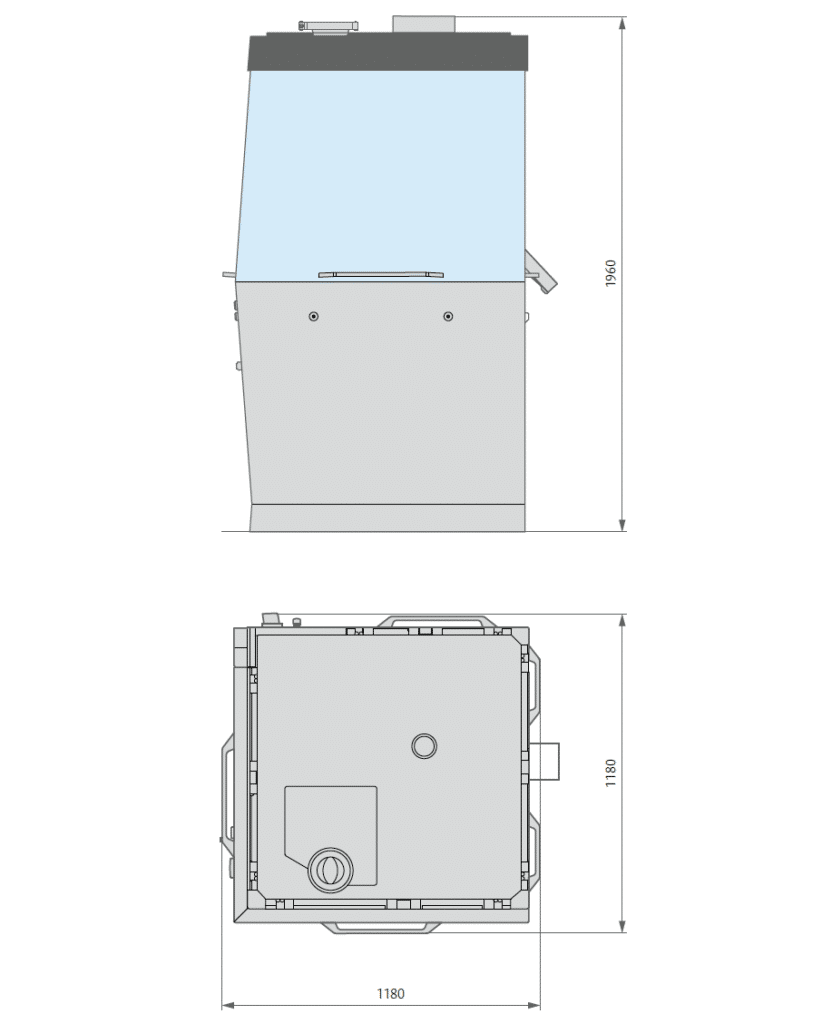

- Machine Layout

| ADAPTA 7 | ADAPTA 21 | ADAPTA 50 | |

| Maximum output (capsules/hour) | 7,000 | 21,000 | 50,000 |

| Number of capsules per cycle | 1 | 3 | 7 |

| Capsule size | 5-000, DB E-AA | 5-000, DB E-AA | 5-000, DB E-AA |

| Maximum installed power (KW) | 11 | 11 | 12.5 |

| Aspiration | 3,200 l/m – 2,400 mmH2O | 3,200 l/m – 2,400 mmH2O | 4,800 litres/minute – 3,100 mm H2O |

| Compressed air | 100 l/m – 6 bar | 100 l/m – 6 bar | 100 l/min – 6 bar |

| Vacuum | 100 m3/h – 3 mbar (abs.) | 100 m3/h – 3 mbar (abs.) | 100 m3/h- 3 mbar (abs.) |

| Standard voltage | 400 V – 50 Hz | 400 V – 50 Hz | 400 V 50 Hz |

| Weight (kg) | 1,200 | 1,250 | 1,300 |