Quick access to IMA Sectors:

Pharma | Food & Dairy | Confectionery | Tea & Beverage | Coffee | Personal & Home Care | Tissue & Nonwoven | Automation | Tobacco | E-Commerce |THE MOST COMPREHENSIVE RANGE OF COUNTING TECHNOLOGIES

COMPLETE SOLUTIONS FOR PHARMACEUTICALS, NUTRACEUTICALS AND VITAMINS

Unrivalled variety of counting equipment that constitutes a complete offering on the market.

Complete, efficient and highly versatile, modular packaging lines can incorporate a selection of unscramblers, desiccant inserters, bottle blowers, cottoners, cappers, tablet elevators and electronic and slat tablet counting machines. Thanks to the combined expertise of IMA Safe, IMA Life and IMA BFB, these make up the range of counting solutions to satisfy all customer needs. Counting technologies for electronic counting machines include the Optical Sensor, a highly reliable and accurate, infrared emitter and receiver able to scan at a very high rate (16 scans per millisecond). A detected product that falls between minimum and maximum Dark Time is considered a good product and counted. Sensors can detect and count two tablets falling closely together but not completely overlapped. The dust-resistant Electrostatic Field Sensor (E.F.S.) is suitable for dusty products, able to discriminate between referenced good product and broken tablets, empty or half empty capsules. The mass of the tablet is given by a reference curve. The system works for both capsules and tablets. Counting machines can also be equipped with a Camera Vision System to detect cross-contamination (products with different colours).

IMA is the only company offering complete lines of counting machines:

unscramblers, desiccant inserters, bottle blowers, cottoners, cappers, tablet elevators and of course electronic and slat tablet counting machines, the heart of our production.

|

||||||

| Unscramber | Dessicant Inserter | Tablet/Capsule Counting | Cotton Iserter | Capper | Induction Sealer | Retorquer |

Counting Technologies for electronic counting machines

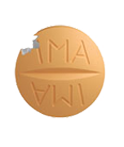

Optical sensor

Very reliable and accurate, infrared emitter and receiver is able to scan at very high rate (16 scans per millisecond). A detected product that falls between minimum and maximum Dark Time is considered a good product and counted. Sensors can detect and count two tablets falling closely together but not completely overlapped.

E.F.S. (Electrostatic field sensor)

Suitable for dusty products, E.F.S. is a unique sensor control able to discriminate between referenced good product and broken tablets, empty or half empty capsules. The mass of the tablet is given by a reference curve. E.F.S. is a dust resistant sensor. The system is suitable to handle both capsules and tablets and it is dust immune.

| The table below indicates the detection capabilities of the optical and E.F.S. sensors for different tablet/capsule damage and scenarios. If they are not detected then they will be counted as a good product, if they are detected then the machine will reject the bottle containing that product. | ||||||||

| Half tablet or capsule | Capped tablet | Tablet chip | Double tablet | Double tablet | Part of tablet | Empty capsule | Half empty capsule | |

|

|

|

|

|

|

|

|

|

| OPTICAL SENSOR | NO | NO | NO | YES (count as double) | NO | NO | NO | NO |

| E.F.S. (ELECTROSTATIC FIELD SENSOR) | YES | YES | YES | YES (Count as double) | YES (Count as double) | NO | YES | YES |

| Tests with active product are needed in order to confirm definitive results. | ||||||||

Additional equipment: Camera Vision System

Counting machines can be equipped with Camera Vision System to detect cross contamination (products with different colours).

Counting Technologies for slat Counting Machines

Trucount scanning System

The revolutionary TruCount® high-speed tablet scanning system scans, evaluates and counts the product before it enters the bottle and ensures 100% count accuracy. Rather than using a vision system, TruCount® provides a fully integrated count verification system that is reliable, easy to set up and eliminates the need for operators. A large array of photo diodes and detectors scan the product nearly 2000 times per second after the tablet leaves the slat. Tablets are fully contained within the manifold to ensure that counted tablets enter the bottle.

Only one supplier for your highly efficient counting lines

IMA can provide complete and efficient packaging lines characterized by a high versatility, modularity according to every type of request. Together with IMA SAFE, IMA LIFE and IMA BFB we can provide a comprehensive counting and packaging solution that covers primary packaging, secondary packaging, and end-of-line solutions.

The strenghts of I-SCAN integrated into the NEW UNILINE

The new I-SCAN tablet counter with product inspection and single tablet rejection capabilities offers higher speeds, flexibility, and advanced options such as integrated torque control on the six capping heads, along with optional cotton insertion, desiccant insertion, Tare/Gross weighing, and induction sealing.

Solutions designed 100% in-house respond to all requests for the containment of solid pharmaceutical shapes in blister packaging. The reliability of our feeding systems minimises the need for operator intervention within the containment cabin, whose accessibility and smooth surfaces simplify cleaning procedures.

|

|