Quick access to IMA Sectors:

Pharma | Food & Dairy | Confectionery | Tea & Beverage | Coffee | Personal & Home Care | Tissue & Nonwoven | Automation | Tobacco | E-Commerce |SL Series

The use of single-dose containers to package pharmaceutical or cosmetic products is becoming increasingly popular thanks to the numerous advantages that this type of container offers in terms of product safety, administration accuracy and ease of use.

The use of single-dose containers to package pharmaceutical or cosmetic products is becoming increasingly popular thanks to the numerous advantages that this type of container offers in terms of product safety, administration accuracy and ease of use.

Multiple opportunities for single-dose containers.

IMA Life filling and sealing machines for single-dose containers ensure overall flexibility so as to meet a wide range of needs, for industrial-scale production or small production batches. The SL is designed and built to fill and seal single-dose plastic containers in 5-unit dose strips with maximum dosing up to 15 ml and equipped with different filling systems according to product viscosity. Thanks to the wide range of models available, IMA Life product portfolio can meet any production specification and layout configuration.

SL SERIES Highlights

- Technical Data

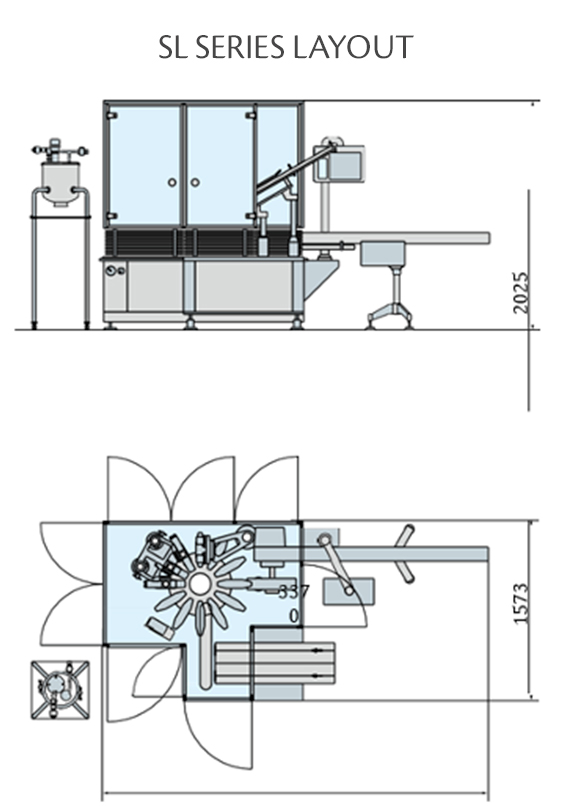

- Machine Layout

| SL SERIES TECHNICAL DATA | |||

| SL 25 | SL 50 | SL 75 | |

| Max. | Max. | Max. | |

| H (mm) | 90 | 90 | 90 |

| L (mm) | 210 | 135 | 95 |

| Dosage (ml) | 10 | 5 | 1 |

| Dosing heads | Up to 5 | Up to 10 | Up to 15 |

| Production speed | Up to 25 strip/min | Up to 50 strip/min | Up to 75 strip/min |

| Installed power | 6 kw | 6 kw | 6 kw |

| Standard power supply | 400 V – 50 Hz | 400 V – 50 Hz | 400 V – 50 Hz |

| Weight (kg) | 2200 | 2600 | 2800 |