Designed specifically to handle loose or bundled bottles, even with unusual shapes, this servo driven, top loading case packer benefits from excellent ergonomics, ensures top-level output and can manage two cases simultaneously.

Designed specifically to handle loose or bundled bottles, even with unusual shapes, this servo driven, top loading case packer benefits from excellent ergonomics, ensures top-level output and can manage two cases simultaneously.

Top loading, high speed case packing.

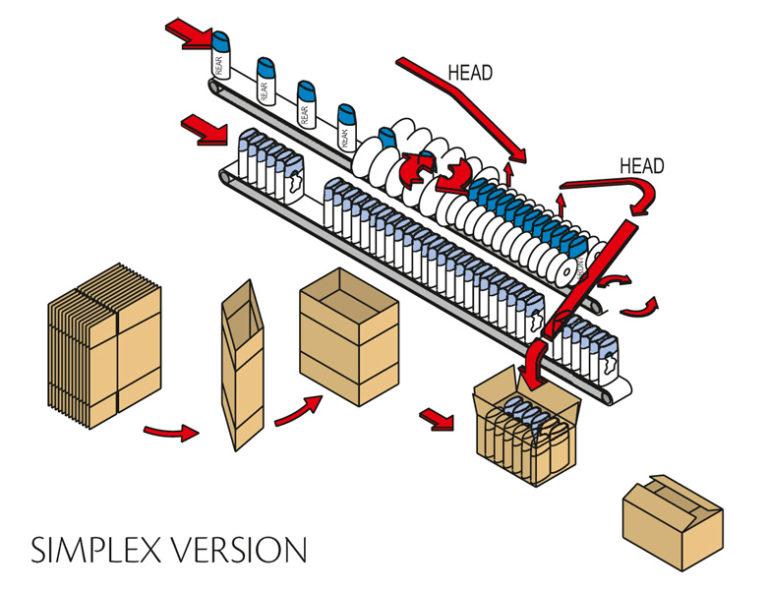

With a remarkably compact footprint, the monobloc 3754 case-packer has been designed to provide operating ergonomics, smooth handling and high-speed processing. Erecting, loading and sealing up to 50 cases/min, the 3754 (in its duplex version) is equipped with 2 infeed hoppers and a case magazine handling 2 rows of cases.

The forced opening and closing groups process 2 cases simultaneously, further boosting machine output.

To assure perfect handling of difficult shaped bottles, the infeed system is equipped with non-stop worm-screws to correctly orientate the containers.

3754 Highlights

- Technical Data

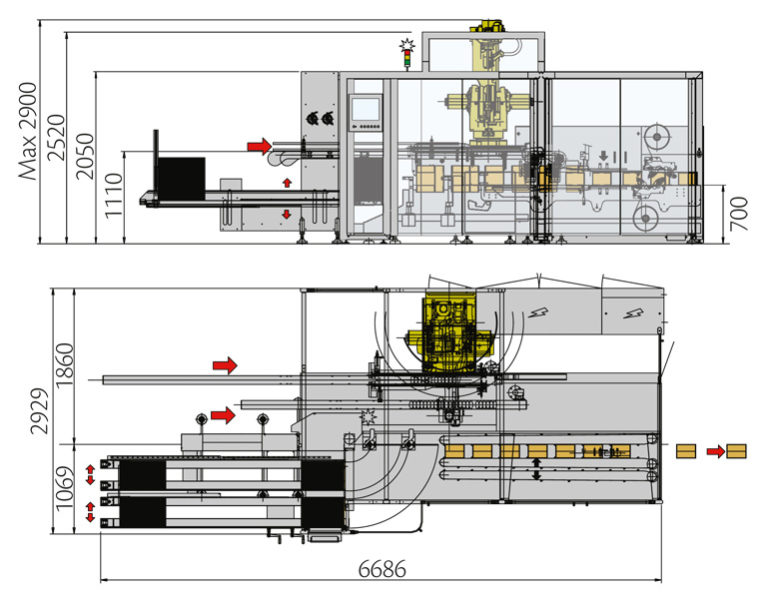

- Machine Layout

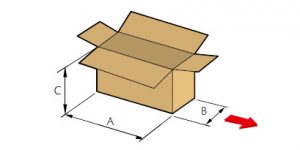

| TECHNICAL DATA 3754 | ||||

| Max speed | up to 50 cases/min. | |||

| Product dimensions | A | B | C | |

| Simplex | Min. | 165 | 80 | 165 |

| Max. | 600 | 300 | 300 | |

| Duplex | Min. | 165 | 80 | 165 |

| Max. | 325 | 180 | 300 | |