Designed specifically to manage wrapped or cartoned bar soaps and able to collate and overwrap them in several different bundle configurations, using cellophane, PP and all reel-fed, heat-sealable film types, even very thin.

Designed specifically to manage wrapped or cartoned bar soaps and able to collate and overwrap them in several different bundle configurations, using cellophane, PP and all reel-fed, heat-sealable film types, even very thin.

High speed over wrapping with all types of film.

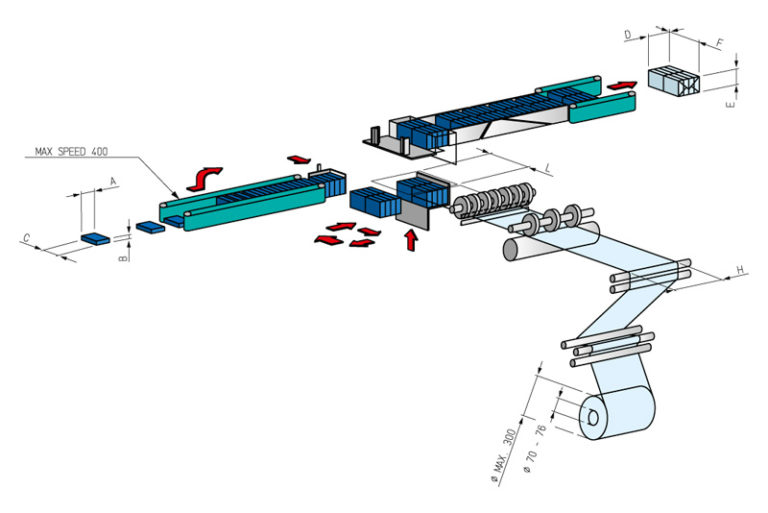

With an output of up to 100 bundles/min., the 3703 can arrange the products wrapping it in one, two or three rows on a single layer.

Bundle collation occurs in line with product exit, but outside the wrapping area.

Product infeed is managed by lateral belts to avoid product sliding due to high feeding speeds and a driven star-wheel in order to turn on edge the incoming products. Final products configuration is achieved by means of a driven collating unit.

Changeover by replacement of pre-assembled and pre-adjusted groups is fast and easy, so as to avoid unwanted downtime.

3703 Highlights

- Technical Data

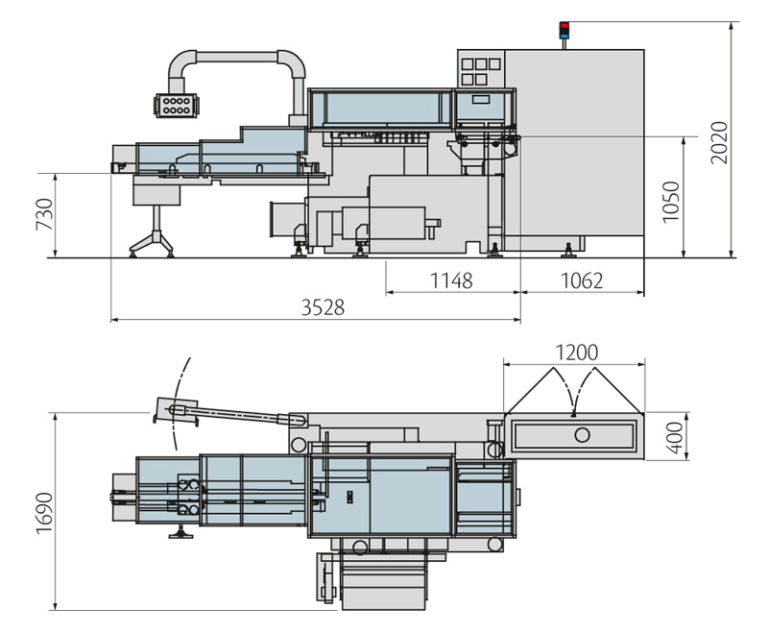

- Machine Layout

| TECHNICAL DATA 3703 | ||||

| Max. Speed | Up to 100 cycles/min. | |||

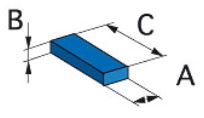

| Product dimensions | A | B | C | |

| 3703BP | Min. | 60 | 23 | 60 |

| Max. | 260 | 100 | 260 | |