PACK FOR TOMORROW • OPEN HOUSE

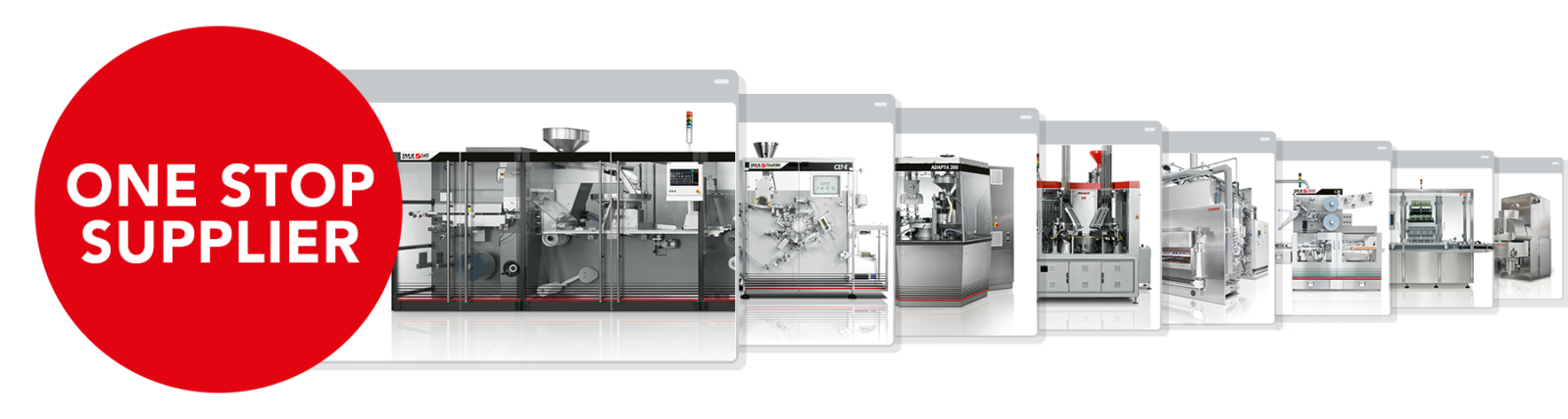

The greatest dairy & food packaging expertise in one place

A high technological profile, the ability to offer tailor-made solutions to satisfy the most sophisticated requests and special attention to service are the pillars that support IMA DAIRY & FOOD’s lasting partnership with the industry’s leading brands.

Consisting of specialised companies, all capable of rapidly meeting customer demands, IMA DAIRY & FOOD offers comprehensive, integrated and marketing-oriented solutions.

IMA DAIRY & FOOD provides state-of-the-art thermoform, fill and seal machines (FFS) for cups, portion packs and stick packs, fill and seal machines (FS) for pre-formed cups and tubs, machines for stand-up pouches, tablet presses for soup cubes or instant drinks, wrapping machines for butter, fresh cheese, processed cheese and soup cubes as well as the downstream equipment for cartoning or tray-packing requirements.

MACHINES ON SHOW

GYRO CUP

Rotary filling and sealing machine

- Interchangeable Filling Stations (Hopper and Direct Feed)

- Innovative central drive solution

- Multi-digit turntable (2, 3 or 4 cups per segment)

- Compact footprint

- Recipe functionality, servo technology.

- Fast format changeover.

ERMETIKA

Pouch filling machine

- Leaking test available: it’s the only machine on the market able to control the sealing of the pouch

- “Filling through the spout” system: the spout is sealed on the pouch before filling

- Continuous motion machine

- Flexible system to handle film and spout/cap from different suppliers

- Shape and size format changeover in 15 minutes

P100

Forming, filling and sealing machine for portion packs

- Entry level/cost effective machine: excellent dosing accuracy

- Very flexible machine in terms of product handled. Customers can change their production during a working week

- Very compact footprint

- Maximum accuracy, precise product cut-off and gentle product handling

MMP400

Modular multipacker

- Modular design

- Suitable to pack all kinds of products such as cartons, bags, flowpacks, bottles, pillows, butter, cheese and cups into wraparound cases, RSC cases, tray or tray with hood

- Product handling by 2 axes Gantry system or 6 axes Fanuc robot

- Hygienic and food grade design (stainless steel upon request)

- Total accessibility and ergonomic design

- Reduced changeover time (minimum number of adjustments)

- Mechanical speed up to 30 cases/min.

PREXIMA

Tablet presses

High efficiency motorization for low temperature tableting, complete separation between processing and mechanical areas, a wide range of systems for consistent die feeding and user friendly HMI: these are the hallmark of PREXIMA tablet presses for all powdery substances, tablet dimensions and production volumes. The machines can be linked to downstream packaging equipment for an integrated line.

Two models will be demonstrated:

- PREXIMA 300 single-sided tablet press for medium production output.

- PREXIMA 800 for high output and double-sided or double layer production.

Discover IMA DIGITAL: a project for PROCESSING and PACKAGING 4.0

Meet IMA Digital @Open House

IMA DIGITAL is the company’s new comprehensive project to tackle the digitization challenge that is transforming the manufacturing world. Businesses face unprecedented disruption.

IMA’s leadership in terms of innovation and technology imposes a highly competitive position also in the challenges of Industry 4.0.

By giving additional value to the packaging industry with empowered machines and services created to deliver predictive and personalized customer’s experiences across all over the value chain.

You will ride through a technological tour in the streamline of digital innovation where technology serves our processes and our products.

Explore the widest range of machines on Videowalls.