PDP Series are specifically engineered to press stock cubes, at speeds ranging from 600 up to 3000 products/minute, in different shapes and sizes, from small 4 gr cubes to the larger 13 gr tablets.

PDP Series are specifically engineered to press stock cubes, at speeds ranging from 600 up to 3000 products/minute, in different shapes and sizes, from small 4 gr cubes to the larger 13 gr tablets.

Reliability, consistent quality, and easy maintenance; the PDP Series, single punch technology

Our PDP series are specifically engineered to press stock cubes, at speeds ranging from 600 up to 3,000 ppm, in different shapes and sizes, from small 4 gr cubes to the larger 13 gr tablets, ensuring consistent quality and weight. Single punch PDP Series has an extremely operator friendly design and concept, providing easy access for maintenance, considerably reducing production downtimes.

The PDP presses can be equipped with automatic product weight adjustments in the loading cells as well as with data collection systems to monitor production performances and analyse root causes of eventual downtimes. Designed with a space-efficient concept to minimise the footprint, excellent hygiene standards are guaranteed, keeping the production area segregated from the mechanical housing.

Through a more effective design, maintenance operations and related costs are drastically reduced, punches and dies can be easily replaced for fast changeovers.

Single punch presses by IMA Corazza can handle different powders, allowing the customer to easily switch from one recipe to another, ensuring high efficiency also with low flowability powders. Combining our state-of-art PDP24 with I10 Side Fold wrapping machine, the whole line can handle a complete size change, allowing the customer to produce easily cubes and tables with the same equipment.

Sustainability

The motorization is handled with the aim to avoid power waste. Kinetic energy generated during braking is shared and absorbed by other modules.

PDP Series Highlights

Product output options preview

- Technical Data

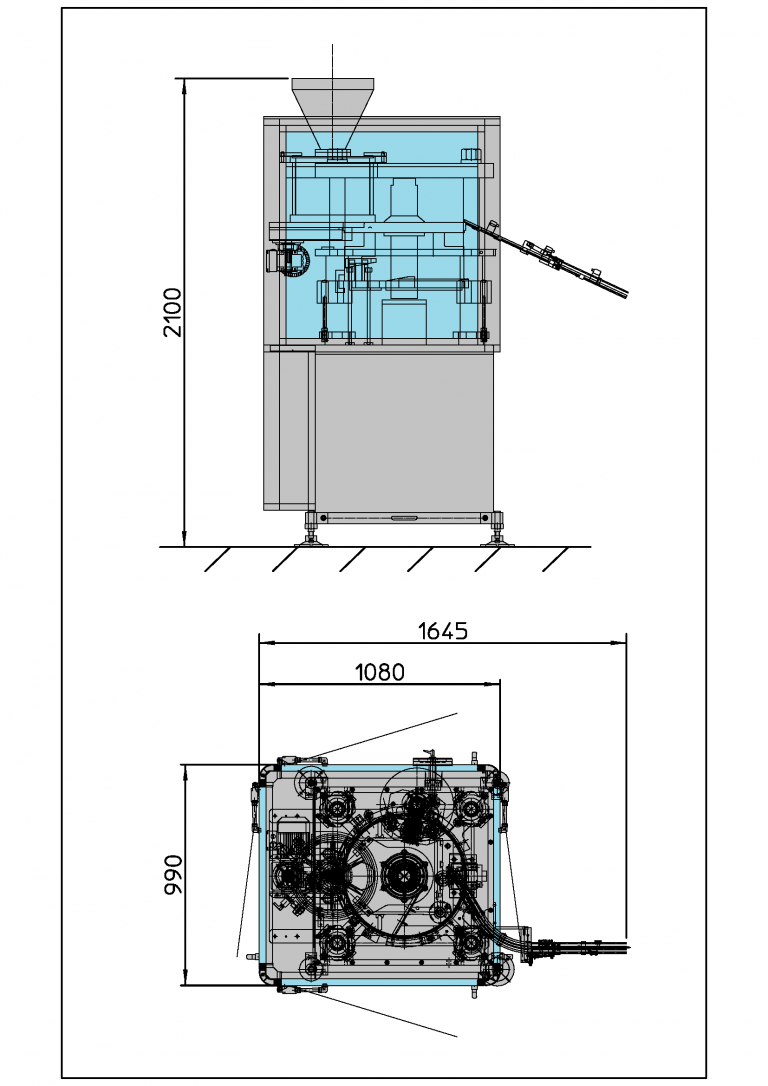

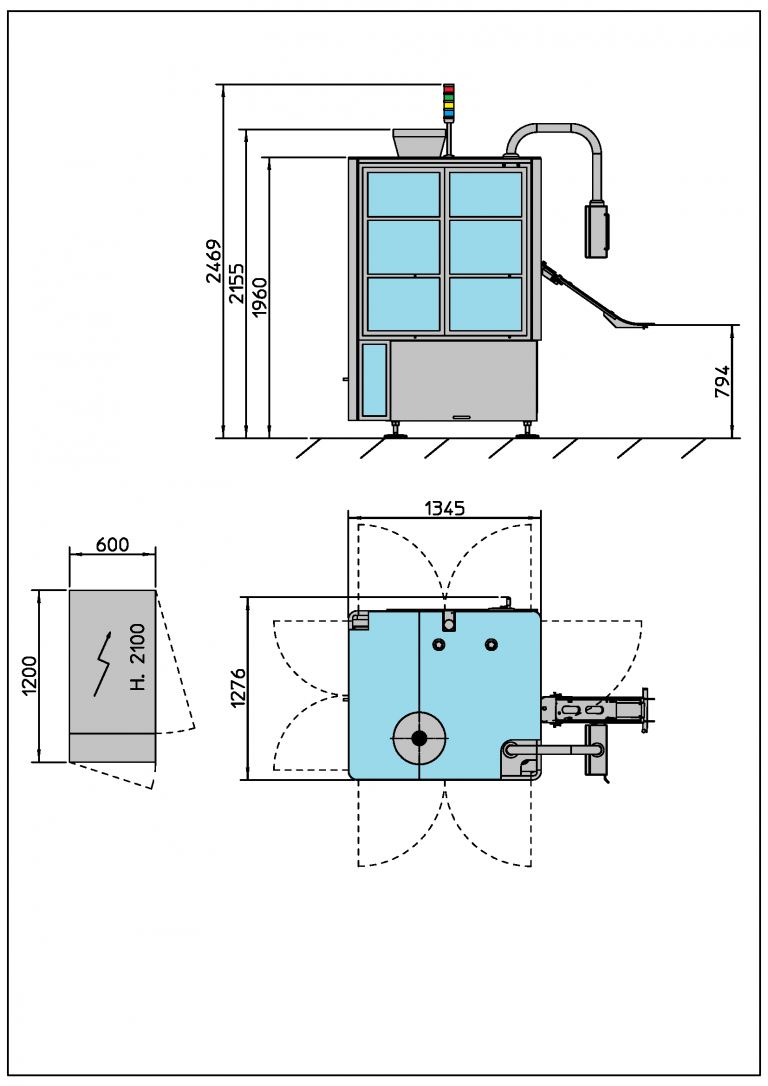

- Machine Layout

| Machine model | PDP18 | PDP/V | PDP HS | PDP 24 | ||||

| Production capacity | Up to 600 portions/min. | Up to 1,000 portions/min. | Up to 850 portions/min. | Up to 1,600 portions/min. | Up to 1,200 portions/min. | Up to 2,400 portions/min. | Up to 1500 portions/min. | Up to 1500 portions/min. |

| Full load current | 3P x 400 Volt – 50 Hz – 9 Amp | 3P x 400 Volt – 50 Hz – 8 Amp | 3P x 400 Volt – 50 Hz – 8 Amp | 3P x 400 Volt – 50 Hz – 9 Amp | ||||

| Compressed air consumption | 125 Nl/min. (min. op. pressure 6 bar) | 150 Nl/min. (min. op. pressure 6 bar) | 150 Nl/min. (min. op. pressure 6 bar) | – | ||||

| Weight | 3,050 Kg approx. | 3,300 Kg approx. | 3,300 Kg approx. | 3,450 Kg approx. | ||||

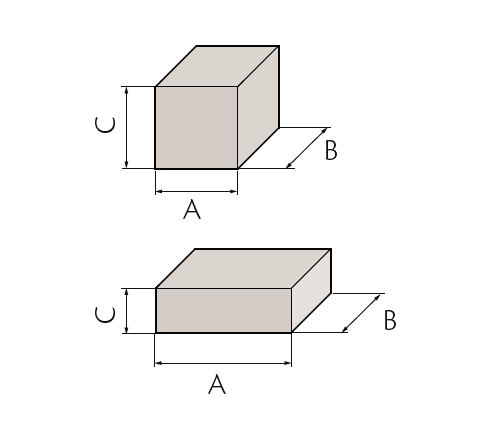

| Shape | Tablet | Cube | Tablet | Cube | Tablet | Cube | Tablet | Cube |

|

Portion dimension

|

A (min ÷ max) | A (min ÷ max) | ||||||

| 13 ÷ 36 | max.15 | 13 ÷ 36 | 15 max. | 13 ÷ 36 | 15 max. | 13 ÷ 36 | 15 max. | |

| B (min ÷ max) | B (min ÷ max) | |||||||

| 13 ÷ 24 | 15 max. | 13 ÷ 24 | 15 max. | 13 ÷ 24 | 15 max. | 13 ÷ 24 | 15 max. | |

| C (min ÷ max) | C (min ÷ max) | |||||||

| 8 ÷ 14 | 15 max. | 8 ÷ 14 | 15 max. | 8 ÷ 14 | 15 max. | 8 ÷ 14 | 15 max. | |

| Weight (min ÷ max) | Weight (min ÷ max) | |||||||

| 8 g ÷ 13 g | 4 g ÷ 5 g | 8 g ÷ 13 g | 4 g ÷ 5 g | 8 g ÷ 13 g | 4 g ÷ 5 g | 8 g ÷ 13 g | 4 g ÷ 5 g | |