Designed to offer high speed production, simple operation and a compact footprint, the MS260 comes in different versions according to specific needs. High speed stacking, carton tilting and a shrink tunnel can be integrated into this high-performance unit.

Designed to offer high speed production, simple operation and a compact footprint, the MS260 comes in different versions according to specific needs. High speed stacking, carton tilting and a shrink tunnel can be integrated into this high-performance unit.

Top speed, totally easy, extremely compact.

Very clean balcony-type construction with maximum accessibility to all main parts to facilitate maintenance and cleaning operations. The MS260 stretch banding and shrink wrapping machine has been specifically designed to meet the requirements of a market where demand is growing more and more for extremely compact, easy-to-operate, high production speed machines. The machine can be equipped with a high speed stacking unit (MS260A) or with a carton tilting unit (MS260AM) capable of standing on edge as many as 400 cartons per minute.

MS260 SERIES Highlights

- Technical Data

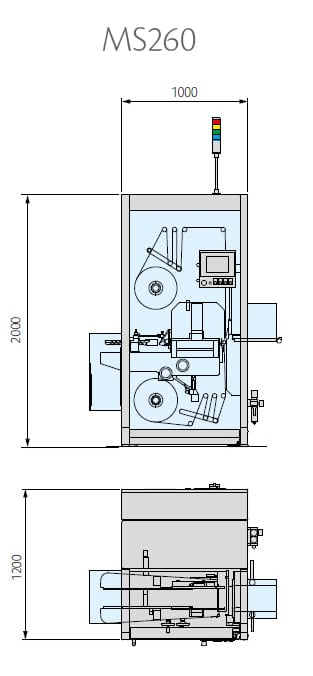

- Machine Layout

| TECHNICAL DATA MS260 SERIES | |||||||

| Production dimensions | A | B | C | D | E | F | H |

| Min. | 20 | 12 | 60 | 60 | 30 | 60 | 40 |

| Max. | 150/360 | 90 | 200 | 210/360 | 210 | 200 | 250 |

| Rial diameter | Std.Ø 400 mm | ||||||