menu

This is Food & Dairy Website

Quick access to IMA Sectors:

Pharma

|

Food & Dairy

|

Confectionery

|

Tea & Beverage

|

Coffee

|

Personal & Home Care

|

Tissue & Nonwoven

|

Automation

|

Tobacco

|

E-Commerce

|

Food & Dairy Website

Choose the market

blur_on

I SERIES - Bottom fold

Pressed Soup Cube Wrapping

The I Series bottom fold wrapping machines are designed to package pressed soup cubes at a low humidity and strenght

The I Series bottom fold wrapping machines are designed to package pressed soup cubes at a low humidity and strenght

A full range of solutions for bottom fold wrapping technologies

This machine series stands out for a fully mechanical execution that can grant long lasting reliability and easy maintenance operations.

The wide range of pressed cube wrapping solutions are able to satisfy all customer’s requirements.

I6 and I6V are suitable for cubes and tablets and can wrap up to 800 ppm.

IDP and IDPS machines are suitable for customers who prefer running at a lower speed up to 600 ppm.

nature_people

Sustainability

|

|

| The motorization is handled with the aim to avoid power waste. Kinetic energy generated during braking is shared and absorbed by other modules. | It allows the use of sustainable and recyclable packaging materials. |

settings_applications

Production Plant

IMA Corazza

I Series - Bottom fold Highlights

1.

Packaging materials include: Alufoil, AluBOPP, BOPP, thermo-welding aluminium, coupled aluminium OPP (according to version)

2.

Print centring device controlled by brushless motor for greater accuracy (according to version)

3.

Special device on wrapping section eliminates unwanted vibration (according to version)

4.

Side and lower sealing sections have an automatic product ejection in case of machine stoppage (according to version)

5.

Easy opening feature on request, designed both for cube and bar size.(according to version)

6.

Simple to operate and easy to maintain with a space saving footprint

Product output options preview

keyboard_arrow_left

keyboard_arrow_right

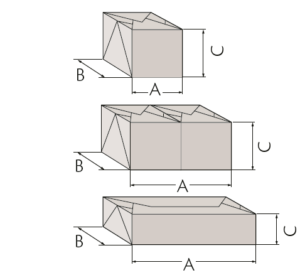

Wrapping - Cube

Wrapping - Tablet

Wrapping - Double cube

- Technical Data

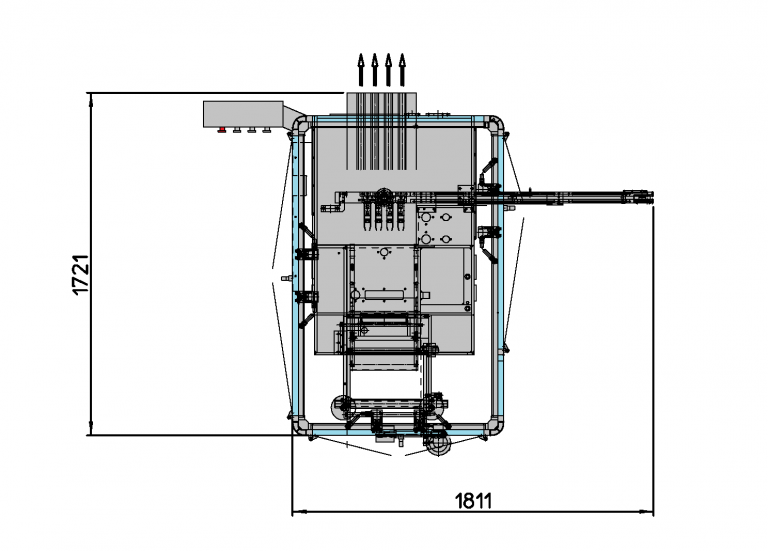

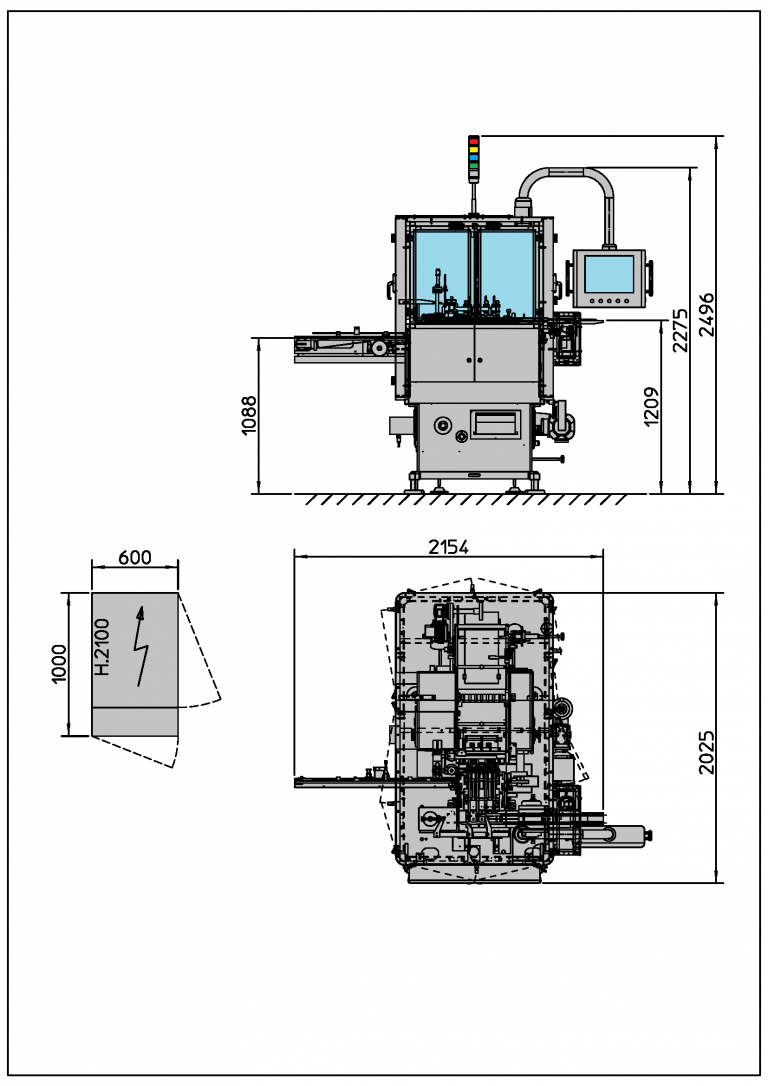

- Machine Layout

| Machine model | IDP | IDP/S | I6/V | I6 | I6/V2 | ||

| Production capacity | Up to 550 portions/min. | Up to 500 portions/min. | Up to 800 portions/min | Up to 750 portions/min | Up to 700 portions/min | ||

| Full load current | 3P x 400 Volt 50 Hz – 10 Amp |

P x 400 Volt 50 Hz – 10 Amp |

3P x 400 Volt 50 Hz – 12 Amp |

3P x 400 Volt 50 Hz – 10 Amp |

3P x 400 Volt |

||

| Compressed air consumption | 120 Nl/min. (min. op. pressure 6 bar) | 120 Nl/min. (min. op. pressure 6 bar) | 150 Nl/min. (min. op. pressure 6 bar) | 150 Nl/min. (min. op. pressure 6 bar) | 150 Nl/min. (min. op. pressure 6 bar) | ||

| Weight | 2,000 Kg Approx. | 2,000 Kg Approx. | 1,500 Kg Approx. | 1,500 Kg Approx. | 1,500 Kg Approx. | ||

| Shape | Tablet | Cube | Tablet | Cube | Double Cube | ||

|

Box dimensions

Other sizes available upon request. |

A (min ÷ max) | ||||||

| 13 ÷ 36 | 15 max. | 13 ÷ 36 | 15 max. | 28 max. | |||

| B (min ÷ max) | |||||||

| 13 ÷ 24 | 15 max. | 13 ÷ 24 | 15 max. | 14 max. | |||

| C (min ÷ max) | |||||||

| 8 ÷ 12 | 15 max. | 8 ÷ 12 | 15 max. | 14 max. | |||

| Weigth (min ÷ max) | |||||||

| 8g ÷ 12g | 4g ÷ 5g | 8g ÷ 12g | 4g ÷ 5g |

2 x 4g |

|||

markunread

Contact us