The side fold wrapping machine I Series is the latest development in wrapping technology for pressed soup cubes and tablets and it’s designed to offer extremely high efficiency and productivity

The side fold wrapping machine I Series is the latest development in wrapping technology for pressed soup cubes and tablets and it’s designed to offer extremely high efficiency and productivity

Latest-generation side fold wrapping technologies

This fully electronic state-of-the-art machines series stands out for flexibility in format changeover, compact footprint, plug-in design of the main groups and negligible operating costs.

The new HMI facilitates the human-machine communication, providing performance data, statistic report and remote machine assistance.

The I20, high-speed double-lane execution, is able to wrap up to 2.000 ppm.

The I10, medium-speed single-lane execution, reaches up to 1.000 ppm.

Sustainability

|

|

| The motorization is handled with the aim to avoid power waste. Kinetic energy generated during braking is shared and absorbed by other modules. Engineered preventing the usage of water cooling systems. Disegned to reduce the usage of vaccum system consumption. |

It allows the use of sustainable and recyclable packaging materials. |

I Series - Side Fold Highlights

Product output options preview

- Technical Data

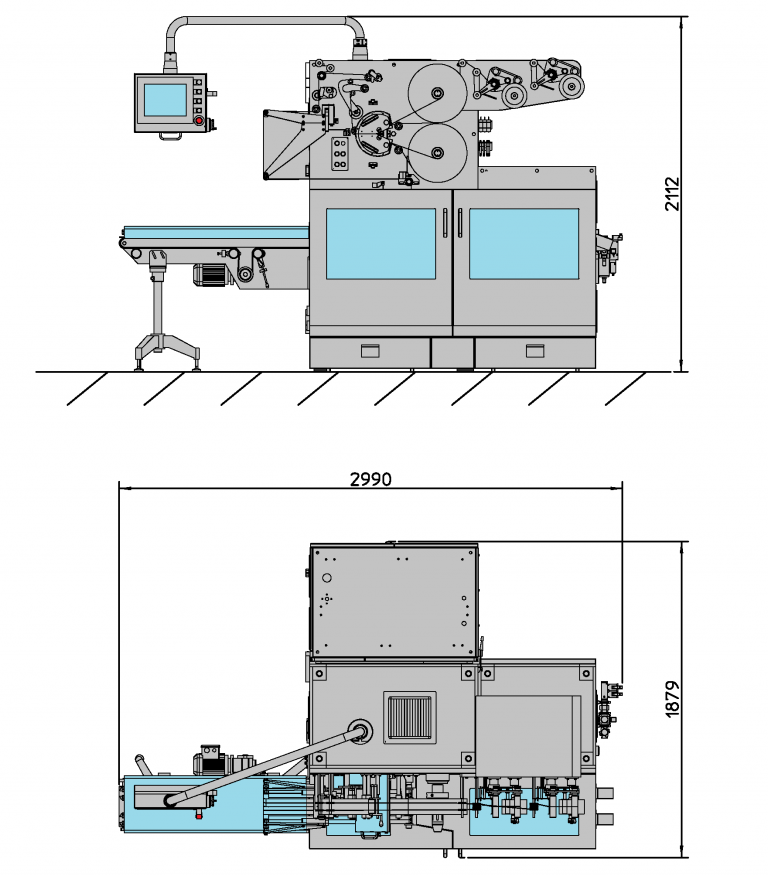

- Machine Layout

| Machine model | I10 | I20 | ||||

| Production capacity | Up to 1,000 portions/min. | Up to 2,000 portions/min. | ||||

| Full load current | 3P x 400 Volt – 50 Hz – 10 Amp | 3P x 400 Volt – 50 Hz – 10 Amp | ||||

| Compressed air consumption | 400 Nl/min. (min. op. pressure 6 bar) | 400 Nl/min. (min. op. pressure 6 bar) | ||||

| Weight | 2,700 Kg approx. | 3,100 Kg approx. | ||||

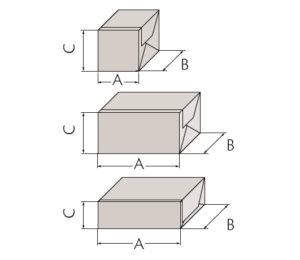

| Shape | Tablet | Cube | Double Cube | Tablet | Cube | Double Cube |

|

Box dimensions

Other sizes available upon request. |

A (min ÷ max) | |||||

| 13 ÷ 36 | 15 | 28 | 13 ÷ 36 | 15 | 28 | |

| B (min ÷ max) | ||||||

| 13 ÷ 24 | 15 | 14 | 13 ÷ 24 | 15 | 14 | |

| C (min ÷ max) | ||||||

| 8 ÷ 12 | 15 | 14 | 8 ÷ 12 | 15 | 14 | |

| Weight (min ÷ max) | ||||||

| 8g ÷ 12g | 4g ÷ 5g | 2 x 4g | 8g ÷ 12g | 4g ÷ 5g | 2 x 4g | |