menu

This is Food & Dairy Website

Quick access to IMA Sectors:

Pharma

|

Food & Dairy

|

Confectionery

|

Tea & Beverage

|

Coffee

|

Personal & Home Care

|

Tissue & Nonwoven

|

Automation

|

Tobacco

|

E-Commerce

|

Food & Dairy Website

Choose the market

blur_on

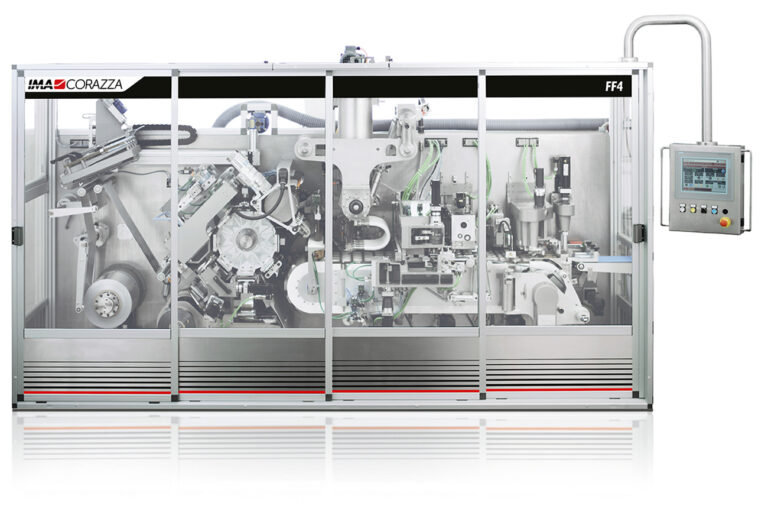

FF4 SERIES

Dosing and Wrapping

The FF4 implements the latest dedicated technologies for the packing of processed, cream or fresh cheese in triangular, square or rectangular portions

The FF4 implements the latest dedicated technologies for the packing of processed, cream or fresh cheese in triangular, square or rectangular portions

Flexible, accurate, efficient

Space-saving footprint with a modular design for maximum flexibility and efficiency.

Accurate hot and cold filling and flexible format capabilities are the key benefits of this space-efficient equipment ensuring a production capacity up to 600 ppm. The dosing unit can be cleaned with automatic CIP.

The FF4 can also be executed in a multi-flavor configuration.

nature_people

Sustainability

|

|

| The motorization is handled with the aim to avoid power waste. Kinetic energy generated during braking is shared and absorbed by other modules. The Machine can be equipped with vacuum pumps in order to reduce or avoid compressed air consumption. Disegned to reduce the usage of vaccum system consumption. |

It allows the use of sustainable and recyclable packaging materials. |

settings_applications

Production Plant

IMA Corazza

FF4 Series Highlights

1.

Cantilever inline machine with 4 tracks with stainless steel execution

2.

Hot and cold filling handled by the same 4-lane syringe filling unit

3.

High-precision dosing unit with automatic feedback control from optional weight-checker

4.

All machine components easily accessed for standard intervention procedures

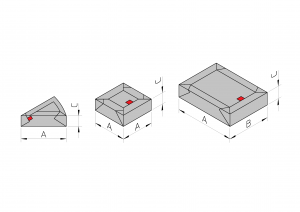

Product output options preview

keyboard_arrow_left

keyboard_arrow_right

Cheese - Triangular portion

Cheese - Square portion

Cheese - Rectangular portion

- Technical Data

- Machine Layout

| Machine model | FF4 | FF4R | |||

| Production capacity | Up to 600 portions/min. | ||||

| Full load current | 3P x 400 Volt – 50 Hz – 12 Amp | ||||

| Compressed air consumption | 180 Nl/min. (min. op. pressure 6 bar) | ||||

| Vacuum | 25 m³/h (op. vacuum 600 ± 50 mm Hg) | ||||

| Weight | 5,600 Kg approx. | ||||

| Shape | Triangular 6/6 | Triangular 8/8 | Triangular 12/12 | Square | Rectangular |

|

Box dimensions

|

A (min ÷ max) | ||||

| 54,5 max. | 54,5 max. | 54,5 max. | 25 ÷ 45 | 25 ÷ 60 | |

| B (min ÷ max) | |||||

| – | – | – | – | 25 ÷ 55 | |

| C (min ÷ max) | |||||

| 26 max. | 26 max. | 26 max. | 8 ÷ 26 | 8 ÷ 26 | |

| Weight (min ÷ max) | |||||

| 10g ÷ 34g | 10g ÷ 32g | 10g ÷ 23g | 10g ÷ 40g | 10g ÷ 40g | |

markunread

Contact us