The FF100 machine series ensures hot and cold fill applications for processed cheese. Comprising 3vversions, each solution is based on a modular concept to allow for maximum flexibility and simplicity in shapes and sizes changeover

The FF100 machine series ensures hot and cold fill applications for processed cheese. Comprising 3vversions, each solution is based on a modular concept to allow for maximum flexibility and simplicity in shapes and sizes changeover

Adaptable, user-friendly concept

According to customer requirements, the FF100 Series of dosing and wrapping equipment covers a wide spectrum of cold and hot fill applications:

- The FF100 (hot fill) handles various formats (from 50 up to 250 gr) at speeds ranging from 70 to 100 ppm.

- The FF100BP (hot fill) handles large portions (from 250 up to 500 gr) at speeds between 40 and 70 ppm.

- The FF100K (cold fill) processes various formats (from 50 up to 250 gr) at speeds up to 80 ppm and is designed for portfolio style wrapping.

The modular concept behind each model allows an easy conversion from one shape to the next and can be implemented without excessive downtime for machine set-up.

Sustainability

|

|

| The motorization is handled with the aim to avoid power waste. Kinetic energy generated during braking is shared and absorbed by other modules. The Machine can be equipped with vacuum pumps in order to reduce or avoid compressed air consumption Disegned to reduce the usage of vaccum system consumption. |

It allows the use of sustainable and recyclable packaging materials. |

FF100 Series Highlights

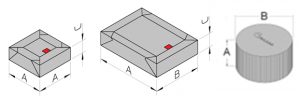

Product output options preview

- Technical Data

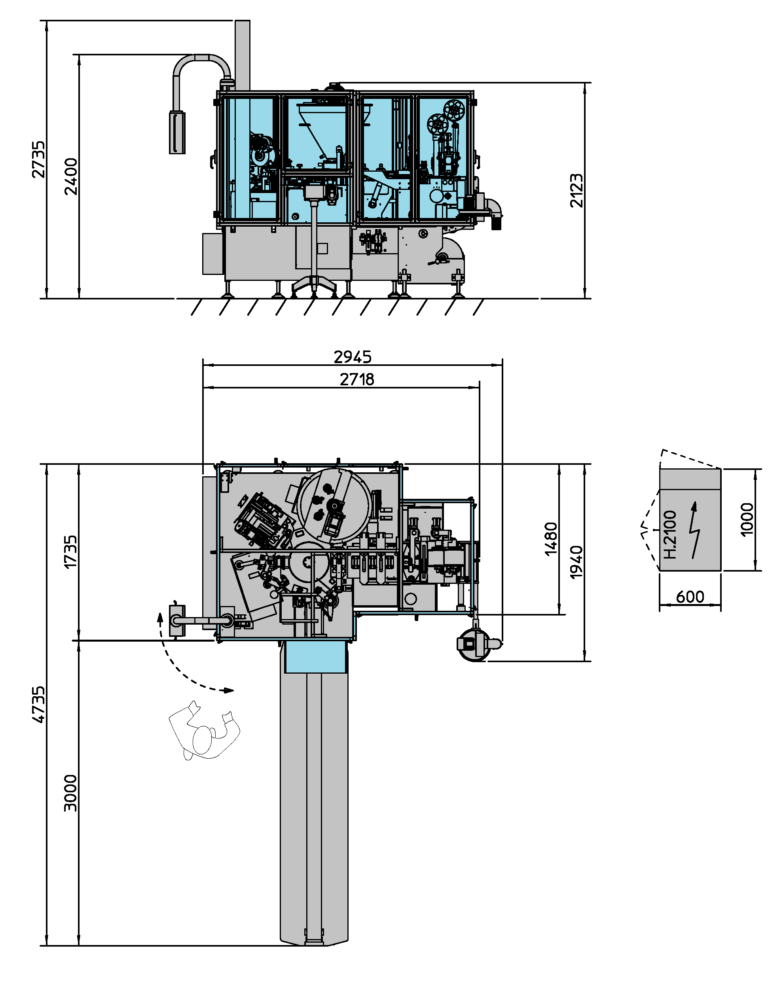

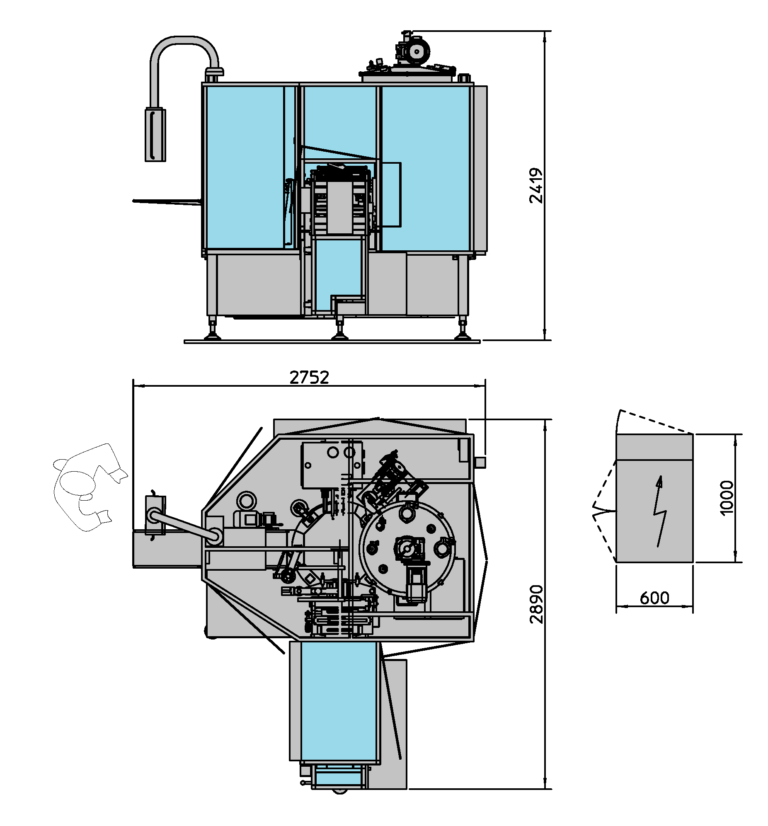

- Machine Layout

| Machine model | FF100 | FF100K | FF100BP | |||

| Production capacity | Up to 70-110 portions/min | Up to 80 portions/min | Up to 40-70 portions/min | |||

| Full load current | 3P x 400 Volt – 50 Hz – 8,5 Amp | 3P x 400 Volt – 50 Hz – 7 Amp | 3P x 400 Volt – 50 Hz – 12 Amp | |||

| Compressed air consumption | 240 Nl/min. (min. op. pressure 6 bar) | 380 Nl/min. (min. op. pressure 6 bar) | 160 Nl/min. (min. op. pressure 6 bar) | |||

| Vacuum | 40 m³/h (op. vacuum 600 ± 50 mm Hg) | 60 m³/h (op. vacuum 600 ± 50 mm Hg) | 60 m³/h (op. vacuum 600 ± 50 mm Hg) | |||

| Weight | 3,800 Kg Approx. | 3,600 Kg Approx. | 3,800 Kg Approx. | |||

| Shape | Square | Rectangular | Round | Square | Rectangular | Rectangular |

|

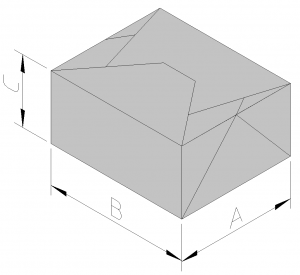

Box dimensions

|

A (min ÷ max) | |||||

| 78 max. | 110 max. | 80 max. | 80 max. | 50 ÷ 65 | 160 max. | |

| B (min ÷ max) | ||||||

| 78 max. | 58 max. | 50 max. | 80 max. | 50 ÷ 110 | 80 max. | |

| C (min ÷ max) | ||||||

| 39 max. | 36 max. | – | 40 max. | 20 ÷ 35 | 40 max. | |

| Weight (min ÷ max) | ||||||

| 30g ÷ 250g | 30g ÷ 250g | 30g ÷ 250g | 30g ÷ 250g | 30g ÷ 250g | 200g ÷ 500g | |