The FD Series machines dose and wrap soup cubes at the speed best suited to specific production requirements, preparing the wrapping material, dosing, folding and closing the wrapping, followed by subsequent weight-checking

The FD Series machines dose and wrap soup cubes at the speed best suited to specific production requirements, preparing the wrapping material, dosing, folding and closing the wrapping, followed by subsequent weight-checking

Accurate soup cube processing at any speed

According to customer requirements, the FD Series is able to handle different wrapping materials, like parchment, backed alufoil or other flexible materials. For greater speed and for customers aiming for maximum productivity together with quality and precision, the FD12 is the high-speed answer, reaching 1.200 ppm.

Set along the 8 lanes of the in-line filling conveyor, pre-formed foil segments are filled with the bouillon paste. The foil is then folded over and the wrapping is pressed closed.

For medium speed requirements the FD8 doses and wraps 4 cubes simultaneously and the optimum processing speed can be set via the operator panel, up to 800 ppm.

In order to satisfy all the market requests in terms of speed, the FD220 is the low speed machine model, reaching up to 280 ppm.

Sustainability

|

|

| The motorization is handled with the aim to avoid power waste. Kinetic energy generated during braking is shared and absorbed by other modules. | It allows the use of sustainable and recyclable packaging materials. |

FD Series Highlights

Product output options preview

- Technical Data

- Machine Layout

| Machine model | FD8 | FD12 | FD220 |

| Production capacity | Up to 800 portions/min. | Up to 1,200 portions/min. | Up to 280 portions/min. |

| Full load current | 3P x 400 Volt – 50Hz – 17 Amp | 3P x 400 Volt – 50Hz – 25 Amp | 3P x 400 Volt – 50Hz – 5 Amp |

| Compressed air consumption | 400 Nl/min. (min. op. pressure 6 bar) | 450 Nl/min. (min. op. pressure 6 bar) | 263 Nl/min. (min. op. pressure 6 bar) |

| Vacuum | – | – | 3 m³/h (op. vacuum 600 ± 50 mm Hg) |

| Weight | 5,500 Kg Approx. | 8,800 Kg Approx. | 3,500 Kg Approx. |

|

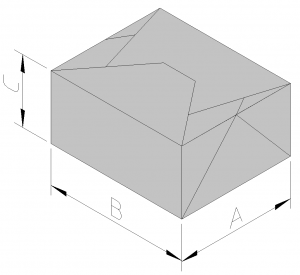

Box dimensions

|

A (min ÷ max) | ||

| 20 ÷ 27 | 20 ÷ 27 | 20 ÷ 27 | |

| B (min ÷ max) | |||

| 25 ÷ 35 | 25 ÷ 35 | 25 ÷ 35 | |

| C (min ÷ max) | |||

| 7 ÷ 15 | 7 ÷ 15 | 7 ÷ 15 | |

| Weight (min ÷ max) | |||

| 9g ÷ 13g | 9g ÷ 13g | 9g ÷ 13g | |