The COPPARAPID 4000 provides you with the latest technology for filling of all a number for products in different sizes cups or tubs,

The COPPARAPID 4000 provides you with the latest technology for filling of all a number for products in different sizes cups or tubs,

Latest development for the filling and sealing machine

The COPPARAPID 4000 provides you with the latest technology for filling of pasty products into different sizes of pre-formed cups.

Thanks to a single platform utilising as many standard components as possible, it is possible to cover a large range of container profiles and shapes.

The machine is able to accommodate products by direct feed, compensator, or can be installed with a hopper for products with alternative characteristics.

Quick and easy changeover for format parts combined with the recipe functionality achieved with the use of integrated servo technology has minimized downtime between product and packaging changeovers.

Sustainability

|

|

|

Usage of paper based materials. |

COPPARAPID 4000 Highlights

Product output options preview

- Technical Data

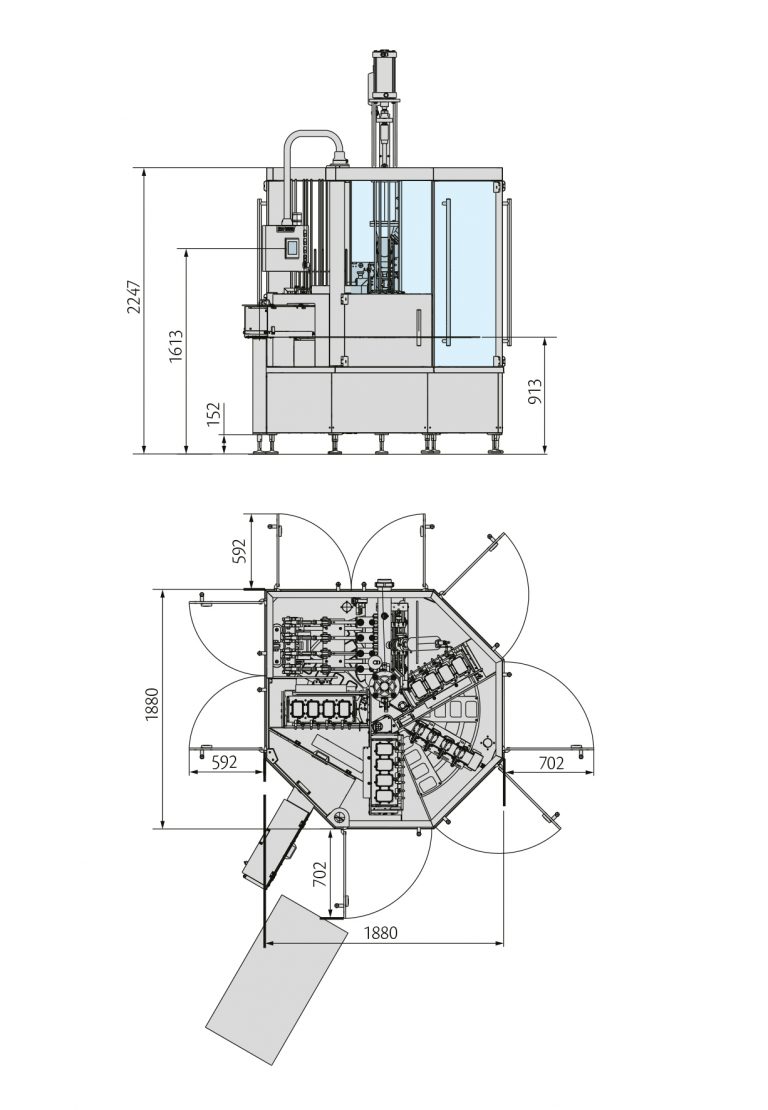

- Machine Layout

| TECHNICAL DATA COPPARAPID 4000 | ||

| Production outputs | 2 digit | 4,800 cups/h |

| 3 digit | 7,200 cups/h | |

| 4 digit | 9,600 cups/h | |

| Installed power | 7,5 kW | |

| Compressed air pressure | 6 bar | |

| Compressed air consumption | 30 m3/h | |

| Machine weight | 3,000 kg | |

| CUP/TUB STANDARDS AND CAPABILITIES | ||||

| DIGIT | ROUND | SQUARE | HEIGHT | FILLING RANGE |

| 2 | 160 mm | 182 x 136 mm | 140 mm | 220 cc – 1,100 cc |

| 3 | 127 mm | 150 x 104 mm | 140 mm | 120 cc – 600 cc |

| 4 | 101 mm | 95 x 122,5 mm | 140 mm | 60 cc – 300 cc |