The AD8F is a wrap-around solution for the packaging of square and rectangular portions of processed cheese. By taking flat blanks, the machine forms cartons with tucked-in end flaps and glued longitudinal seams

The AD8F is a wrap-around solution for the packaging of square and rectangular portions of processed cheese. By taking flat blanks, the machine forms cartons with tucked-in end flaps and glued longitudinal seams

Efficient cartoning for non-triangular portions of processed cheese

Using open flat blanks for 2-4-6-8 count boxes, the AD8F receives suitably spaced cheese portions via the in-line synchronised belt from the conveying/bundle forming device.

Portions are already pre-grouped in appropriately arranged layout, making the wrap-around cartoning efficient and straightforward. Tucked-in end flaps and glued seams complete the process which reaches speeds of up to 120 boxes/min.

Sustainability

|

|

| The motorization is handled with the aim to avoid power waste. Kinetic energy generated during braking is shared and absorbed by other modules. The Machine can be equipped with vacuum pumps in order to reduce or avoid compressed air consumption. Disegned to reduce the usage of vaccum system consumption. |

It allows the use of sustainable and recyclable packaging materials. |

AD8F Highlights

Product output options preview

- Technical Data

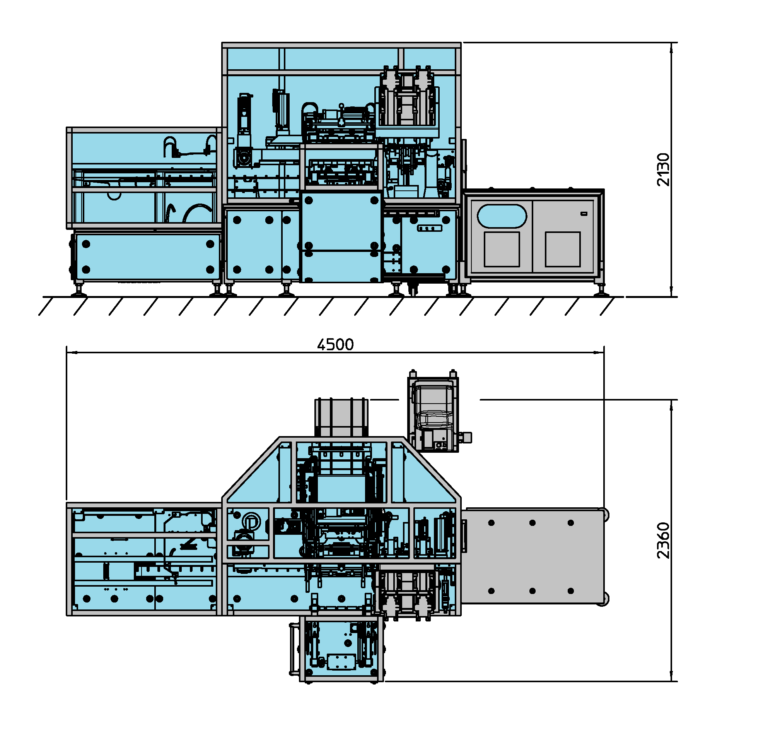

- Machine Layout

| Production capacity | Up to 120 boxes/min. |

| Full load current | 3P x 400 Volt – 50 Hz – 7 Amp |

| Compresse air consumption | 220 Nl/min. (min. op. pressure 6 bar) |

| Weigth | 3,400 Kg Approx. |

|

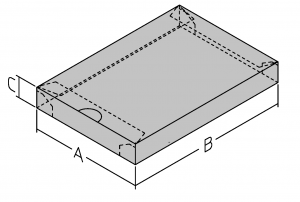

Box dimensions

|

A (min ÷ max) |

| 39 ÷ 78 | |

| B (min ÷ max) | |

| 78 ÷ 156 | |

| C (min ÷ max) | |

| 15 max. | |

| Lanes | 1 ÷ 2 |