Over wrapping for parallelepiped cosmetic and toiletry items, the 3705 is a high-speed machine for individual and/or multiple product packs on one layer, using cellophane, PVC, PP and all other reel-fed, heat-sealable films.

Over wrapping for parallelepiped cosmetic and toiletry items, the 3705 is a high-speed machine for individual and/or multiple product packs on one layer, using cellophane, PVC, PP and all other reel-fed, heat-sealable films.

High-quality individual or multiple wrapping for regular products.

With an output of up to 300 bundles/min, the 3705 is a top-performing over wrapping machine for individual and/or multiple parallelepiped product packs.

With an oil-tight steel frame containing all motions, this machine benefits from the smooth speeds of a servo-controlled main motor which eliminates all abrupt stop-start issues. Changeover by replacement of pre-assembled and pre-adjusted groups is fast and easy, so as to avoid unwanted downtime.

3705 Highlights

- Technical Data

- Machine Layout

| TECHNICAL DATA 3705 | ||||

| Wrapping film | CELLOPHANE.PE | |||

| Max. speed | 250/300 | |||

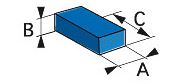

| Product dimensions | A | B | C | |

| 3705 A | Min. | 25 | 15 | 60 |

| Max. | 140 | 50 | 220 | |

| 3705 E | Min. | 45 | 15 | 60 |

| Max. | 80 | 50 | 210 | |