Quick access to IMA Sectors:

Pharma | Food & Dairy | Confectionery | Tea & Beverage | Coffee | Personal & Home Care | Tissue & Nonwoven | Automation | Tobacco | E-Commerce |Coffee Degassing Systems

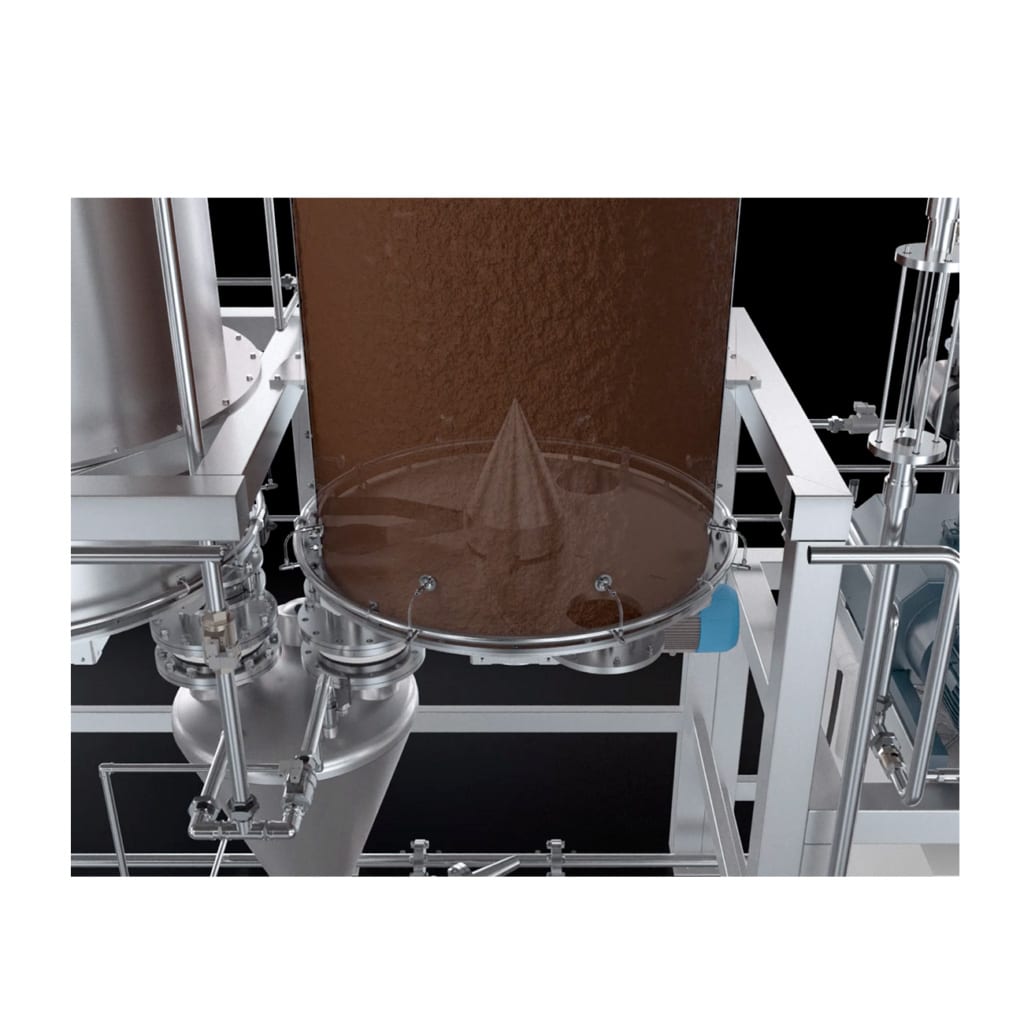

Different degassing systems available in various configurations for the desired degassing process.

Different degassing systems available in various configurations for the desired degassing process.

Degassing Process

Particular attention must be paid to the degassing process. Degassing is a natural chemical reaction that happens inside the beans once roasted and ground. Preventing package inflation and avoiding oxidation are the main factors that have led to the spread of degassing technologies over recent years, especially in the single-serve market. Depending on the room temperature, on roasting parameters, granulometry and the pressure of the coffee inside the storage silos, degassing time can range from 4 to 48 hours.

Production requirements mean degassing time must be reduced to as little as possible, without any aroma loss. The technologies used to accelerate degassing times make it possible to reduce the time, while still preserving the quality of the product.

IMA Petroncini has developed different degassing systems available in various configurations for the desired degassing process. The degassing can be done either in natural conditions with aroma protection by nitrogen, or with an acceleration of the process by using the vacuum technology combined with nitrogen injection. The very next-generation degassing solution is meant to accelerate the degassing process in a vacuum closed circuit with nitrogen injection and product recirculation: that’s Petroncini CO-Tube degassing system.

Sustainability

CO-Tube Degassing System can reduce nitrogen consumption by recycling the gas needed for the degassing process.

Degassing Systems Highlights

Zero Oxygen inside the circuit

CO-Tube is a system capable of accelerating the degassing time through the deep vacuum technology up to -800 mbar, with a nitrogen injection.

The mechanical recirculation of the product used in the new CO-Tube degassing system is an innovation on the market compared to other systems existing. It enables the ground coffee to homogeneously make contact with the nitrogen, keeping the product homogeneous in the silo.

Furthermore, the most innovative CO-Tube feature is linked to the closed-circuit adopted, the unique system available on the market today able to partial recover the nitrogen needed during the process. Furthermore, this specific process engineering combines the possibility to set the final CO2 percentage desired as a parameter of each recipe.

As a result of the degassing time and CO2 parameters, it’s possible to customize the desired ending product and aromas.

Related products

Array

(

[body_class] =>

[no_index] =>

[no_follow] =>

[seo_image] =>

[seo_title] =>

[seo_description] =>

[rel_market] => Array

(

)

[clone_list] => Array

(

)

[embed_iframe] =>

[form_price] =>

[contact] => sales.coffee@ima.it

[thread_tag] =>

[tile_description] => Following the same principle of maintaining the product homogenised and perfecly mixed, preserving the coffee aroma and preventing the oxidation, Petroncini provides the very best trasport solutions.

[tile_speed] =>

[cover_macro] => 2121

[cover_name_type] => txt

[cover_name] => Ground Coffee Handling and Conveying

[cover_descriptor] =>

[cover_focus_on] => 1

[news] =>

[thumbnail] => 4755

[tag_line] => ExtraMAX and the gentle handling

[overview] => A crucial point in ground coffee processing is linked to extraction from the silos. Ground coffee must be properly homogenised and dosed, avoiding agglomeration in the bottom of the silo. We have engineered ExtraMAX, mechanical extractor to avoid demixing and agglomeration of the product with a flat extraction system, suitable for filter, Espresso and Moka coffee. Compared to other vibrating systems, the ExtraMAX system can effectively homogenise the product with accurate control of the dosage, which is impossible with vibrating devices.

Following the same principle of maintaining the product homogenised and perfecly mixed especially once ground, preserving the coffee aroma and preventing the oxidation at the same time, Petroncini provides the very best trasport solutions.

[overview_buttons] => Array

(

[buttons_on] =>

[view_default] =>

[buttons_items] =>

)

[sustainability] =>

[highlights_on] => 1

[focus_on] => 1

[versions_on] => 1

[addon_on] =>

[output_on] =>

[technical_data] =>

[layouts] =>

[technical_video] =>

[technical_video_image] =>

[brochure] =>

[main_video] =>

[gallery] =>

[related] => manual

[line_step] => Array

(

[0] => 4

)

[aseptic] => both

[market_products] => Array

(

[0] => 617

)

[market_packs] => Array

(

)

[market_packs_specs] => Array

(

)

[market_brands] => Array

(

[0] => 13723

)

[market_plants] => Array

(

[0] => 3885

)

[technologies] => Array

(

[0] => 190

[1] => 123

[2] => 117

)

[cover_focus_content] => Handling solutions to preserve the ground coffee aroma avoiding demixing

[buttons_on] => 1

[view_default] => 1

[buttons_items] => Array

(

[0] => Array

(

[acf_fc_layout] => private

[button_id] =>

[button_class] =>

[text] => contact us

[icon] => mail

[form_email] => sales.coffee@ima.it

[type] => contact

[private_product] =>

[private_exhibition] =>

[form_type] => contact

[form_id] =>

)

)

[cover_focus_buttons] => Array

(

[buttons_on] => 1

[view_default] => 1

[buttons_items] => Array

(

[0] => Array

(

[acf_fc_layout] => private

[button_id] =>

[button_class] =>

[text] => contact us

[icon] => mail

[form_email] => sales.coffee@ima.it

[type] => contact

[private_product] =>

[private_exhibition] =>

[form_type] => contact

[form_id] =>

)

)

)

[highlights] => Array

(

[0] => Array

(

[highlight] => Tubolar disc conveyor ideal to avoid demixing and oxidation of the product in capsules.

)

[1] => Array

(

[highlight] => Petroncini TPA Pneumatic Transport

System for ground coffee, suitable for the long distances and high production rate.

)

[2] => Array

(

[highlight] => Air tight ground coffee systems under controlled atmosphere from grinders to packaging machines.

)

[3] => Array

(

[highlight] => Ground coffee storages are tailor-made based on production requirement and space availability.

)

[4] => Array

(

[highlight] => Special equipment for the continuous homogenization of coffee and spices.

)

[5] => Array

(

[highlight] => Petroncini Handling Vacuum system to avoid any contamination.

)

)

[focus] => Array

(

[image] => 1932

[content] => DuoMIX: Special equipment for the continuous homogenization of coffee and spices

[buttons] => Array

(

[buttons_on] =>

[view_default] =>

[buttons_items] =>

)

)

[versions_title] => Special equipment for the continuous homogenization of coffee and spices

[versions] =>

[versions_thumbnail] => 1931

[versions_tag_line] => Special equipment for the continuous homogenization of coffee and spices

[versions_overview] => Mixing coffee and spices in a Turkish coffee processing plant is a crucial operation, which can be done with the right dosage of the spices. Petroncini provides a continuous powder homogenizer that is suitable for mixing coffee and one selected spice, which can be changed according to the production.

This system is called DuoMIX and it has been engineered by our team to guarantee process reliability and high productivity, from the mixing right up to very specific follow-up handling. The system works continuously and guarantees the consistency and repeatability of the mixing results by setting the percentage range of the desired spice.

[versions_overview_buttons] => Array

(

[buttons_on] => 1

[view_default] => 1

[buttons_items] => Array

(

[0] => Array

(

[acf_fc_layout] => private

[button_id] =>

[button_class] =>

[text] => contact us

[icon] => mail

[form_email] => sales.coffee@ima.it

[type] => contact

[private_product] =>

[private_exhibition] =>

[form_type] => contact

[form_id] =>

)

)

)

[related_products] => Array

(

[0] => 10_1856

[1] => 10_1858

[2] => 10_1048

)

)

Array

(

[body_class] =>

[no_index] =>

[no_follow] =>

[seo_image] =>

[seo_title] =>

[seo_description] =>

[rel_market] => Array

(

)

[clone_list] => Array

(

)

[embed_iframe] =>

[form_price] =>

[contact] => sales.coffee@ima.it

[thread_tag] =>

[tile_description] => Coffee grinding is a crucial step in coffee processing and, when done properly, it can dramatically improve coffee extraction and aroma retention, thereby optimizing the brewed coffee quality.

[tile_speed] =>

[cover_macro] => 2134

[cover_name_type] => txt

[cover_name] => Grinders

[cover_descriptor] =>

[cover_focus_on] => 1

[news] =>

[thumbnail] => 1930

[tag_line] => Blades and stone grinders

[overview] => Coffee grinding is a crucial step in coffee processing and, when done properly, it can dramatically improve coffee extraction and aroma retention, thereby optimizing the brewed coffee quality.

Petroncini provides blades and rolls grinders for small and large productions, ensuring reproducible production standards, in terms of consistency of particle size and flexibility, according to the requirements.

Industrial coffee grinders are able to obtain the perfect coffee particle size, suitable to any brewing style, including Soluble, Espresso and Ultrafine coffee types, with capacities ranging from 90 up to 9,000 kg/hour.

[overview_buttons] => Array

(

[buttons_on] =>

[view_default] =>

[buttons_items] => Array

(

[0] => Array

(

[acf_fc_layout] => file

[button_id] =>

[button_class] =>

[text] => Download the brocure

[icon] => explore

[link] => 4748

[tab] =>

)

)

)

[sustainability] =>

[highlights_on] => 1

[focus_on] => 1

[versions_on] => 1

[addon_on] =>

[output_on] =>

[technical_data] =>

[layouts] =>

[technical_video] =>

[technical_video_image] =>

[brochure] => Array

(

[ID] => 3600

[id] => 3600

[title] => THE IMA COFFEE HUB

[filename] => THE-IMA-COFFEE-HUB_I23_EN.pdf

[filesize] => 6117357

[url] => https://ima.it/coffee/wp-content/uploads/sites/10/2023/04/THE-IMA-COFFEE-HUB_I23_EN.pdf

[link] => https://ima.it/coffee/homepage/the-ima-coffee-hub_i23_en/

[alt] =>

[author] => 11

[description] =>

[caption] =>

[name] => the-ima-coffee-hub_i23_en

[status] => inherit

[uploaded_to] => 5

[date] => 2023-04-11 09:57:38

[modified] => 2024-09-13 09:05:16

[menu_order] => 0

[mime_type] => application/pdf

[type] => application

[subtype] => pdf

[icon] => https://ima.it/coffee/wp-includes/images/media/document.png

)

[main_video] =>

[gallery] =>

[related] => manual

[line_step] => Array

(

[0] => 4

)

[aseptic] => both

[market_products] => Array

(

[0] => 617

)

[market_packs] => Array

(

)

[market_packs_specs] => Array

(

)

[market_brands] => Array

(

[0] => 13723

)

[market_plants] => Array

(

[0] => 3885

)

[technologies] => Array

(

[0] => 190

)

[cover_focus_content] => Shop and industrial coffee grinders for any brewing style, from 90 to 9000kg per hour.

[buttons_on] => 1

[cover_focus_buttons] => Array

(

[buttons_on] => 1

[view_default] =>

[buttons_items] => Array

(

[0] => Array

(

[acf_fc_layout] => private

[button_id] =>

[button_class] =>

[text] => CONTACT US

[icon] => mail

[form_email] => sales.coffee@ima.it

[type] => contact

[private_product] =>

[private_exhibition] =>

[form_type] => contact

[form_id] =>

)

)

)

[highlights] => Array

(

[0] => Array

(

[highlight] => Petroncini blades and rolls grinders are perfect applications for a high-precision processing.

)

[1] => Array

(

[highlight] => Rolls grinders are available with two or three stages of grind, controlling gaps and speeds.

)

[2] => Array

(

[highlight] => Water-cooled rolls and coffee temperature systems.

)

[3] => Array

(

[highlight] => Homogeniser and chaff crusher/densifier ensure consistent density during the production.

)

[4] => Array

(

[highlight] => Grinding blades made in chrome-magnesium hard steel, available in different sizes and even for Turkish coffee style.

)

[5] => Array

(

[highlight] => Forced air cooling system installed on the blades grinders ensure preserving the coffee quality and organoleptic properties.

)

)

[focus] => Array

(

[image] => 2135

[content] => T-Crusher

homogeniser and chaff densifier

[buttons] => Array

(

[buttons_on] => 1

[view_default] => 1

[buttons_items] => Array

(

[0] => Array

(

[acf_fc_layout] => private

[button_id] =>

[button_class] =>

[text] => CONTACT US

[icon] => mail

[form_email] => sales.coffee@ima.it

[type] => contact

[private_product] =>

[private_exhibition] =>

[form_type] => contact

[form_id] =>

)

)

)

)

[versions_title] => Consistent density during and after grinding

[versions] =>

[versions_thumbnail] => 1931

[versions_tag_line] => Consistent density during and after grinding

[versions_overview] => Petroncini has developed the T-Crusher, a ground coffee crusher capable of minimising the visibility of chaff in the coffee, thus uniforming the appearance of the ground coffee.

This works by pressing the coffee in a certain area, where there are blades that work at high speed. In addition, for the most demanding customers, we provide a special vibrating sieve, able to completely remove any presence of chaff in the coffee, even the finest.

[versions_overview_buttons] => Array

(

[buttons_on] =>

[view_default] =>

[buttons_items] =>

)

[view_default] =>

[buttons_items] => Array

(

[0] => Array

(

[acf_fc_layout] => private

[button_id] =>

[button_class] =>

[text] => CONTACT US

[icon] => mail

[form_email] => sales.coffee@ima.it

[type] => contact

[private_product] =>

[private_exhibition] =>

[form_type] => contact

[form_id] =>

)

)

[related_products] => Array

(

[0] => 10_1854

[1] => 10_1857

[2] => 10_1858

)

[canonical_url] =>

)

Array

(

[body_class] =>

[no_index] =>

[no_follow] =>

[seo_image] =>

[seo_title] =>

[seo_description] =>

[rel_market] => Array

(

)

[clone_list] => Array

(

)

[embed_iframe] =>

[form_price] =>

[contact] => sales.coffee@ima.it

[thread_tag] =>

[tile_description] => Squared, polygonal or circular silos for small and big capacity equipped with fall shock absorbers and multidischarge systems for the maximum product preservation with easy access and cleaning.

[tile_speed] =>

[cover_macro] => 1908

[cover_name_type] => txt

[cover_name] => Roasted Coffee Storaging

[cover_descriptor] =>

[cover_focus_on] => 1

[cover_focus_content] => Flexible storaging solutions and gentle handling thanks to anti-breakaging devices

[buttons_on] =>

[cover_focus_buttons] => Array

(

[buttons_on] =>

[view_default] =>

[buttons_items] =>

)

[news] =>

[thumbnail] => 1907

[tag_line] => Maximum preservation of the coffee beans

[overview] => Once roasted, it is extremely important to preserve the integrity of the beans, because a fall of more than 500 mm risks damaging them. Petroncini provides squared, polygonal or circular silos for small and big capacity.

Silo capacity can vary from a few hundred kg up to many tons and the shape depends on the capacity and available space. Inside every silo and every silo cell, special devices are installed to gently escort the coffee during its fall. There are different types of shock absorbers available, also designed to avoiding product obstruction especially considering the high production capacity up to 5 tons per hour.

[overview_buttons] => Array

(

[buttons_on] =>

[view_default] =>

[buttons_items] =>

)

[sustainability] =>

[highlights_on] => 1

[highlights] => Array

(

[0] => Array

(

[highlight] => Squared, polygonal or circular silos for small and big capacity equipped with fall shock absorbers tailored on silo’s capacity.

)

[1] => Array

(

[highlight] => Multidischarge systems with product preservation with easy access and cleaning, efficient and reliable positioning.

)

[2] => Array

(

[highlight] => Receiving cyclones and rotary distributors designed with special shock absorbing material.

)

[3] => Array

(

[highlight] => Internal and external installations and different materials and colour available.

)

[4] => Array

(

[highlight] => Complete automation of the storaging process depending on the plan, for the complete traceability of the coffee batches.

)

)

[focus_on] => 1

[focus] => Array

(

[image] => 370

[content] => Production Manager: Automation - Process - Traceability

[buttons] => Array

(

[buttons_on] => 1

[view_default] => 1

[buttons_items] => Array

(

[0] => Array

(

[acf_fc_layout] => link

[button_id] =>

[button_class] =>

[text] => read the product insight

[icon] => explore

[internal_link] => 1

[link] =>

[link_page] => https://ima.it/coffee/insight/coffee-control-room-coffee-data-management-system/

[tab] =>

)

)

)

)

[versions_on] => 1

[versions_title] => Your partner on production schedule

[versions] =>

[versions_thumbnail] => 1906

[versions_tag_line] => Your partner on production schedule

[versions_overview] => The Production Manager® is the perfect tool for monitoring the production of the batches, starting from the agenda of raw coffee components up to packaged product.

It is a useful dashboard to launch the daily production batches of the roasters, identify quantity of the coffee present in the receiving silos and the roasted and ground storaging sections, avoiding any production and contamination errors.

It has a list of active or past lots for monitoring the relative coffee quantities in the time of interest.

It can also act as a traceability system starting from any area of product interest, from the green lot to the packaged product, and viceversa, thus helping to trace any critical issues.

[versions_overview_buttons] => Array

(

[buttons_on] =>

[view_default] =>

[buttons_items] =>

)

[addon_on] =>

[output_on] =>

[technical_data] =>

[layouts] =>

[technical_video] =>

[technical_video_image] =>

[brochure] => Array

(

[ID] => 1864

[id] => 1864

[title] => THE IMA COFFEE HUB_EN (2)

[filename] => THE-IMA-COFFEE-HUB_EN-2.pdf

[filesize] => 5907878

[url] => https://ima.it/coffee/wp-content/uploads/sites/10/2021/10/THE-IMA-COFFEE-HUB_EN-2.pdf

[link] => https://ima.it/coffee/machine/green-coffee-cleaning-and-sorting-systems/the-ima-coffee-hub_en-2/

[alt] =>

[author] => 2306

[description] =>

[caption] =>

[name] => the-ima-coffee-hub_en-2

[status] => inherit

[uploaded_to] => 1039

[date] => 2021-10-20 11:59:14

[modified] => 2021-11-08 16:04:37

[menu_order] => 0

[mime_type] => application/pdf

[type] => application

[subtype] => pdf

[icon] => https://ima.it/coffee/wp-includes/images/media/document.png

)

[main_video] =>

[gallery] =>

[related] => manual

[line_step] => Array

(

[0] => 3

)

[aseptic] => non_aseptic

[market_products] => Array

(

[0] => 616

)

[market_packs] => Array

(

)

[market_packs_specs] => Array

(

)

[market_brands] => Array

(

[0] => 13723

)

[market_plants] => Array

(

[0] => 3885

)

[technologies] => Array

(

[0] => 189

[1] => 229

)

[related_products] => Array

(

[0] => 10_1853

[1] => 10_1048

[2] => 10_1856

[3] => 10_1798

)

[canonical_url] =>

)