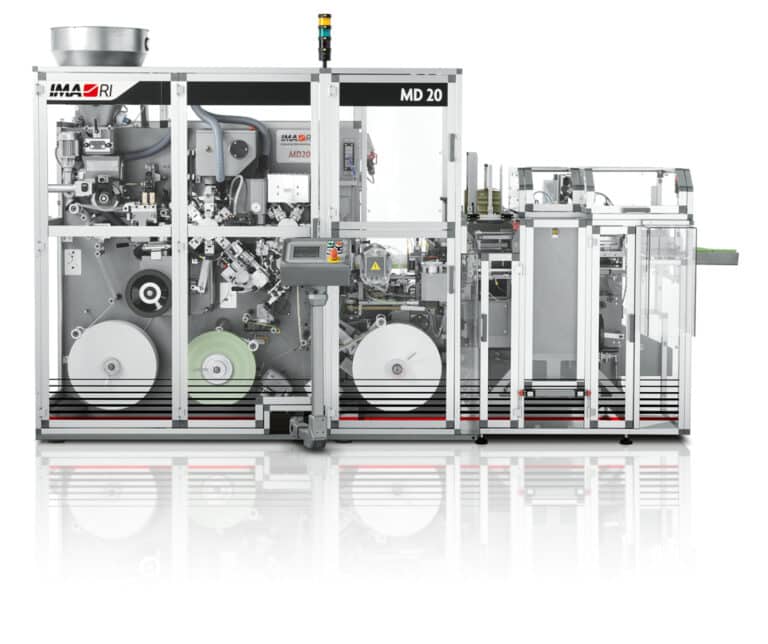

A simple, versatile solution producing knotted teabags for tea and herbs, the MD20 processes up to 200 bags/min and is available for both naked bags and heatsealed outer envelopes. It can be equipped with a cartoning attachment for pre-glued cartons.

A simple, versatile solution producing knotted teabags for tea and herbs, the MD20 processes up to 200 bags/min and is available for both naked bags and heatsealed outer envelopes. It can be equipped with a cartoning attachment for pre-glued cartons.

Simple and versatile

A mid to low-speed packaging machine for non-heatsealable, double-chamber, knotted bags for tea and herbs, the MD20 processes either naked bags or bags in heatsealed outer envelopes.

Equipped with an optional automatic cartoning attachment for pre-glued cartons, the MD20 can also be fitted with a hand-removal unit for counted or uncounted teabags, according to customer needs.

Production is constantly monitored by dedicated supervision software and a video camera which checks knotting and teabag conformity.

Sustainability

The MD20 Plus allows the use of sustainable packaging materials for a complete eco-friendly package.

MD20 Highlights

- Technical Data

- Machine Layout

| TECHNICAL DATA MD20 (WITH HAND REMOVAL) | |

| Overall dimensions | |

| Output | Up to 200 bags/minute |

| Bag capacity | Up to 4.0 grams |

| Bag Volume | Max. 14.2 cm³ |

| Power Installed | 12 kW |

| Power Consumption | 5.5 kW |

| Air Consumption | 500 Nl/min. at 6 bar |

| Machine net weight | Max. 3,600 Kg |

| TECHNICAL DATA MD20 (WITH COUNTING AND HAND REMOVAL) | |

| Overall dimensions | |

| Output | Up to 200 bags/minute |

| Bag capacity | Up to 4.0 grams |

| Bag Volume | Max. 14.2 cm³ |

| Power Installed | 12 kW |

| Power Consumption | 5.5 kW |

| Air Consumption | 500 Nl/min. at 6 bar |

| Machine net weight | Max. 4,000 Kg |

| TECHNICAL DATA MD20 (WITH CARTONING ATTACHMENT FOR PRE-GLUED BOXES) | |

| Overall dimensions | |

| Output | Up to 200 bags/minute |

| Bag capacity | Up to 4.0 grams |

| Bag Volume | Max. 14.2 cm³ |

| Power Installed | 13 kW |

| Power Consumption | 6 kW |

| Air Consumption | 800 Nl/min. at 6 bar |

| Machine net weight | Max. 4,200 Kg |