YOUR ONE-STOP CONTRACTOR FOR WIPES COMPLETE MANUFACTURING LINES

With over 60 years of dedication to automatic machines, the IMA Tissue&Nonwoven Hub is your strategic parner for complete lines from converting to packaging.

Either wet or dry, and shaped in any fold type, IMA can supply forward-looking technologies for nonwovens manufacture.

-

WATER TREATMENT AND LOTION PREPARATION

-

CONVERTING

-

FLOW WRAPPING

-

LID APPLICATION

-

VERTICAL FILLING MACHINES

-

BUNDLING

-

END-OF-LINE

WATER TREATMENT AND LOTION PREPARATION

Wet wipes manufacturing lines start with a water treatment system, consisting of sand filters, electrostatic precipitators, reverse osmosis desalinators and UV sterilizers which, together, provide pure water, bacteriologically suitable to be the base of high quality lotion suitable for wetting wet wipes.

Then follows the lotion preparation system, which is made of a series of pumps, piping and mixing tanks, variable according to the number of served machines and required wet wipes volume production.

IMA carries out each project according to clean design most restrictive standards, with slopes and surfaces capable to avoid any residue during emptying and any bacterial contamination risks, suitable for wet wipes machines.

CONVERTING

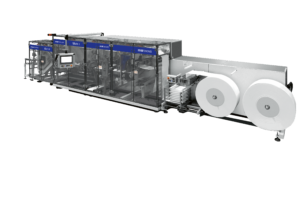

Nonwovens converting is IMA Teknoweb’s core business and the technological field in which is world leader. Our machines cover a full range of processes to manufacture wet and dry wipes, from the raw nonwoven material into the finished product.

Nonwovens converting is IMA Teknoweb’s core business and the technological field in which is world leader. Our machines cover a full range of processes to manufacture wet and dry wipes, from the raw nonwoven material into the finished product.

IMA Teknoweb converters can perform multiple folding types at very high-speed.

Wipes can be folded, and interfolded, in various shapes, such as:

- Lenght-fold (or “flat packs”)

- Cross-fold (Z, double Z, 1/4 fold, 1/6 fold)

- Single rolled

- Perforated rolls

Machine capabilities are characterised by a wide range of substrates (including the most delicate and demanding), reel type (single or semi-jumbo) and process/product controls, to guarantee maximum levels of performance, reliability and compliance with the strictest sanitary specifications.

Sanitary design is paramount when related to the production of medical wipes, baby wipes, or disinfectant wipes. IMA Teknoweb’s converters are constructed with easy-to-clean and durable materials, such as stainless steel. All the surfaces are smooth, to prevent the accumulation of dirt or microbial growth in niches. Machine accessibility is also crucial, in order to allow easy access to operators who need to clean frequently some parts of the machine. Furthermore, CIP (Clean-in-Place) systems allow for automated cleaning without disassembling the machine. IMA Teknoweb’s converters comply with industry regulations and standards related to hygiene and safety, including ATEX regulations.

By adhering to these principles of sanitary design, manufacturers can produce wipes safely and in an hygienic environment, meeting the stringent requirements of industries where cleanliness is of utmost importance.

FLOW WRAPPING

IMA Teknoweb and IMA Ilapak, have constantly developed dedicated flow wrapping solutions by sensing in advance the growth, trends and needs of the sector – with the aim of preserving product safety and hygiene and at same time offering captivating, innovative and reclosable flowpacks using adhesive labels.

In the nonwoven industry, the most popular primary package formats for the wipe applications are pillows flowpack with or without gusseting and the Quattro seal bags.

Ranging in count size from 5 to 10 wipes, to 30 or more, these flat packages are displayed on shelves mostly in trays. They include:

- Cosmetic cleansers, intimate soft cloths, facial towelettes, flushable, lens and screen applications, and many other task specific specialties moist wipes.

- There are also dry nonwoven wipes in economy plastic packaging and some dry specialties in flexible flat packs meant to be wetted by the consumer.

Three types of opening mechanisms show up in the packs: peel and seal; rigid “click;” and more elaborate flip-top molded fitment openers often seen in baby and bathroom wipes. Product designers recognize shelf life as one value driver where they must deliver moisture retention and freshness. IMA Ilapak and IMA Teknoweb, can help accomplishing this task thanks to the precise and reliable technologies applied on its packaging machines.

LID APPLICATION

Any good wet wipes pack is completed by a rigid “click” lid, placed on top of the peel and seal, which helps preserving product fresnhess and extend shelf life.

In order to complete our lines and be able to offer a balanced solution to our customers, we developed in cooperation with IMA CIEMME a lidder capable to reach 150 packs/min speed.

CM Series is composed by 2 machine versions: CM100 can reach up to 95 packs/minute in its high-speed version, equipped with one pick and place unit. CM150 is equipped with 2 pick and place units mounted in series with a single gripping head, boosting the speed up to 150 packs/minute. The latter ensures high precision placement surpassing performances provided by multiple gripping heads (2 or 3). Precision is also driven by robot with joints without mechanical play.

Lids are fed by 2 independent conveyors, reducing lid linear speed and makes the whole process more precise.

One of the latest technological innovation introduced on CM Series is a high-operational autonomy revolving magazine for lids. It consists of 8 columns mounted on a rotating table (600 heigth), with a capacity of 1000/1200 lids ensuring about 20 minutes autonomy. The magazine is equipped with a device for size adjustment to host lids of different dimensions.

TRAYS, CANISTERS, TUBS, REFILL POUCHES

![]() Wipes can be vertically packed in flexible pillows (refill pouches) or rigid containers such as canisters, jars, tubs and tray packs. Across a world of applications, consumers and buyers take note of the container first.

Wipes can be vertically packed in flexible pillows (refill pouches) or rigid containers such as canisters, jars, tubs and tray packs. Across a world of applications, consumers and buyers take note of the container first.

In addition to a consumer-oriented market application, there are also institutional uses of canister wipes across markets, from medical sanitizing to shopping cart wiping and industrial duty. Some of the largest count canisters, pouches and refill packaging contain 1200 or more wipes

IMA Teknoweb lines can integrate cutting-edge and precise vertical filling machinery, specially designed for wet wipes applications.

BUNDLERS

The wet wipes market is moving very quickly towards product sustainability: 100% biodegradable nonwoven is now in common use as is the search for packaging materials that can be totally recycled safely.

The wet wipes market is moving very quickly towards product sustainability: 100% biodegradable nonwoven is now in common use as is the search for packaging materials that can be totally recycled safely.

With this in mind, IMA Teknoweb has developed the MULTI50 handle applicator, in order to reduce the amount of plastic in the multi-bags making the solution totally recyclable. In fact, the multi-bags with handle solution instead of pre-formed bags allows a considerable saving in the amount of material used (the wet wipes packets are held together by a single 38 mm strip of material instead of being totally wrapped).

The machine was also developed to allow the use of the same plastic material both for the adhesive tape and for the handle that is joined to it, so that everything can be recycled together.

The use of a particular photocell capable of recognizing the various colours of the art chosen by the customer for the handle allows to eliminate the typical notch for cutting the films in phase, obtaining an improvement from the qualitative point of view of the presentation of the product.

A new vane belt with paddles was introduced, keeping the products stably grouped during the application of the handle and increasing the quality of the finished product. The packages are processed on the side, allowing also an increase of stacked packets: from 4 (standard multi-bag) up to 5 or 6 if required.

END-OF-LINE

The strength of the IMA Group stands in the vast packaging technologies available, all perfectly combined to complete a line.

The strength of the IMA Group stands in the vast packaging technologies available, all perfectly combined to complete a line.

For this purpose, the IMA End-of-Line Hub includes a full array dedicated to the secondary and tertiary packaging, such as:

- Cartoners

- Tray packers

- Case packers

- Wrap-around

Covering a wide range of speeds, our machines are a perfect completion to converting lines, Reduced machine footprint and great accessibility give the machines a more contemporary feel. Attention to detail is an important part of our manufacturing philosophy. The IMA End-of-Line Hub also offers robotized, integrated case packing and palletizing systems that guarantee flexibility and efficiency in the increasingly demanding packaging market.

More than wipes: our converting solutions for Bathing Gloves, Cosmetic Masks, Floor Cloths.

...and MARK II does it all.

The presence of IMA in the Personal and Home Care segment covers many products. In the nonwovens sector, IMA can provide full lines from converting to packaging for several products, which have seen an increasing interest and market trend lately:

- Cosmetic masks

- Wet mitts and bathing gloves

- Wet floor mops

To cater to the production of such products, IMA has developed various configurations of a very versatile converter named MARK II.

MASKS, MITTS AND GLOVES

MARK II SPA is the version dedicated to cosmetic masks, which can also be printed with customized graphics, reaching a speed of up to 100 ppm. Further customization is dedicated to the final product: in fact, manufacturers can personalize the mask in terms of shape, number of layers and folding.

Mark II Glove can manufacture mono- or bi-facial mitts and bathing gloves with different nonwoven textures, an internal impermeable film to protect the hands of users, and the insertion of an elastic wrist to firmly secure the bathing glove to the user. It reaches a stunning speed of up to 600 ppm, then is flow-packed by IMA’s equipment to complete the line.

FLOOR MOPS

The latest innovation is Mark II Floor, designed for wet floor cloths. The peculiarity of this machine is the ability to manufacture a cloth with different combinations of nonwovens (thicker in the central area and lighter on the sides, which is the part used to fix the mop on the sweeper).

Mark II Floor produces up to 400 pieces per minute, fully wet, packed either in flow packs or trays (which can be plastic or more sustainable material).

BETA SERIES + MARK II SPA: converting and packaging line

A perfect match for your cosmetic maks

In the cosmetic mask processing and packaging field, IMA offers a combination of technologies designed to handle various types and sizes of masks and pack them in a wide range of sachet solutions, always with the highest level of gentleness and efficiency. The Mark II SPA + Beta Series is our quality-oriented solution tailored to accommodate a wide range of sizes and shapes.

Mark II SPA is IMA Teknoweb’s converting machine specially designed for cosmetic masks, capable of trimming the nonwoven fabric into different shapes thanks to a precise rotary die cut. The holes for the eyes, nose, and mouth are seamlessly imprinted on the mask. Masks are first transversally tri-folded or quadri-folded and then discharged at the packaging station.

BETA 360 is IMA Perfect Pack’s vertical sachet machine for 4-seal sachets. It is equipped with a dedicated mask feeder and liquid doser to apply the lotion directly onto the mask inside the sachet. High-quality and aesthetically first-class sachets are produced thanks to a seal made during the stationary phase.

A close-up on dry wipes.

Colour catcher sheets

IMA TEKNOWEB has been supplying from many years dry versions of its converting machines for wipes.

At the forefront of these machines stands GENESIS, known for its exceptional performance and speed.

The configuration of the dry converters depends on customer product requirement, to ensure best reliability and performance. The majority of our converting lines can produce dry wipes with standard fabrics, which means that customer can produce a wider range of products on the very same line. Relevant capital investment is then easily justified.

Moreover, for more specific fabrics IMA TEKNOWEB can set up its converters with dedicated features, due to raw material low basis weight and lack of adhesion between layers. These products include color catcher sheets or softeners sheets among the others.

Speed range goes from 100 cpm with scissor die blades up to 300 cpm with high-speed roto-orbital saw.

Vertical or paddle stackers can be added to increase counts at a speed up to 60 stacks/min.

A pledge towards sutainability: plastic-free and dispersible wipes lines

Every year billions of wet wipes are discarded or flushed, taking up to 100 years to biodegrade, thus adopting sustainable solutions in this market is a mandatory challenge. To reduce wet wipes’ enviromental impact, new materials composed of natural fibers were identified, creating a new kind of nonwoven suitable for sustainable wet wipes.

Still, plastic-free and dispersible wipes are today just a market niche: manufacturing sustainable wet wipes may not be easy for producers, since recyclable raw materials may bring some issues to operations, due to the peculiarity and fragility of these fibers during operations.

To tackle these issues, IMA Teknoweb developed a technology able to eliminate the inefficiencies resulting from these new materials in its length-fold machines.

Sustainability doesn’t stop with converting; IMA Ilapak’s flow wrappers are perfectly integrated into IMA Teknoweb’s wet wipe lines: these high-speed wrapping platforms are equipped with special profile jaws for new generation, plastic-free primary packaging.

To discover more about IMA Teknoweb sustainable solutions, contact us.

Explore IMA ZERO to find out more about IMA Group commitment to sustainability.