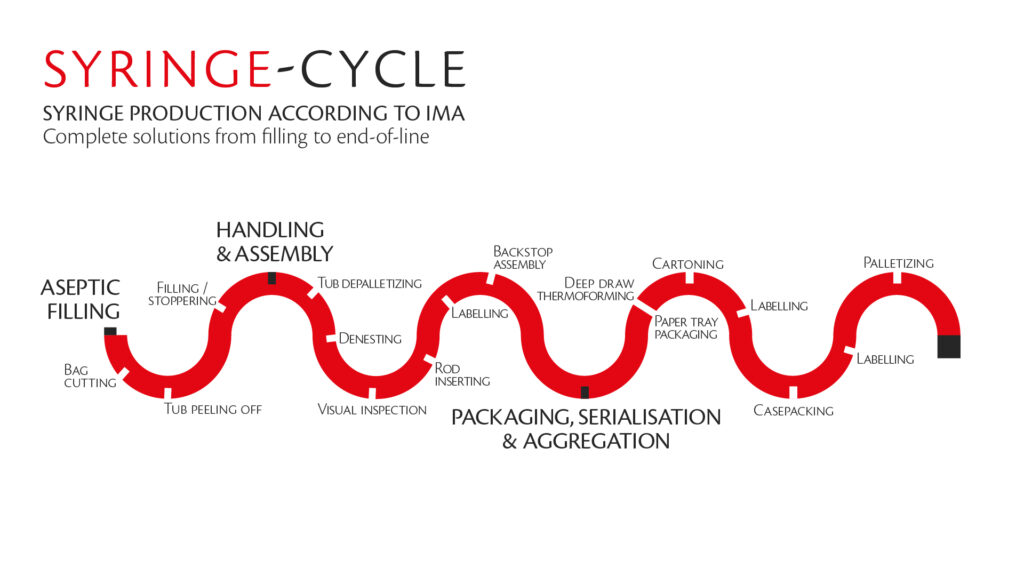

Expand your vision of the “syringe cycle”

The synergy between IMA Life, IMA Safe and IMA BFB ensures a complete and unprecedented range of machines for filling, assembling and packaging syringes. Achieve more thanks to a trusted partner who will help you overcome every production complexity in this market.

Define a fully customised production line.

With IMA, syringe production is exceptionally modular. Choose from a vast range of specific applications for your product and decide how you want to put them together.

Guarantee safe operation throughout your production process. The IMA range is designed specifically for this market and every phase is managed by state-of-the-art technologies.

Configure your production batches rapidly. An IMA line guarantees set-up and size changeover times like no other on the market.

Design your line with IMA experts to meet your layout needs and optimise your production space.

- Aseptic Filling

- Visual inspection

- Handling and assembly

- Tray packaging

- Horizontal Cartoning

- Carton labelling

- Case packing

- Palletizing

Advanced Aseptic technology

Product fill-finish in an aseptic environment are operations that must be precise and reliable. The systems we specifically design for this purpose meet all market demands as well as maintaining a certain level of flexibility while complying with the strict and rigid regulations set by this field.

The new generation of IMA Life machines for filling, stoppering and capping syringes and other RTU (Ready to Use) components fully satisfy these requirements with extra benefits too. In addition to being compact and ergonomic, they boast advanced robotics that replace standard machine motions, ensuring a more smooth process in a smaller space and drastically minimising human intervention.

A wide range of inspection options

Inspecting pre-filled syringes is a challenge because of the specific characteristics of this type of product and international standards that require every single unit to be visually inspected and proven to be free of particle contamination.

The Antares Vision Group VRI-VI 060 S series targets the highest quality standards through an advanced Automatic Visual Inspection system that detects particles, cosmetics and filling level defects.

Container closure integrity testing is also conducted with integrated high voltage technology to detect any leakages that may affect the guaranteed sterility of the product.

Based on a fast, smooth handling system including features such as individually motorised grippers and guide-less conveying, the VRI – VI 060 S series can handle both glass and plastic PFS and guarantees 100% quality inspections with suspensions and waterlike or viscous products.

Its continuous motion also reduces vibration during transport, allowing advanced speeds of up to 600 pcs/min to be reached.

Superior Care

When handling, denesting and assembling pre-filled syringes, extreme precision is needed to safeguard the integrity of the product and its contents.

IMA BFB product handling solutions are designed to manipulate nested and de-nested syringes with extremely accurate loading and unloading operations. These systems are highly flexible and can be placed at the beginning or end of the line or converted into a buffer for product accumulation during line stops.

Robotized palletization and de-palletization systems are also available for handling tubs with nested syringes that need to be inserted or withdrawn from storage lines. In entirely automatic production processes, these dynamic solutions can meet even the highest productivity demands.

Today, IMA Life’s vast experience can bring even safer and more efficient handling to your entire line, from denesting to assembly. We are always at your side with the highest level of efficiency and automation to guarantee agile, safe, precise performance. You can even shape your assembly process according to your production requirements by configuring up to 3 operations: rod insertion, back-stop application and labelling.

Flexible solutions for Tray Packaging

IMA has developed a range of flexible solutions for the secondary packaging of syringes in trays. Our C260/C360 deep-draw thermoforming machine series guarantees high-quality production standards for packaging in formable trays with careful product handling, high productivity and advanced flexibility in terms of product feeding and machine configuration.

A paper tray packaging alternative is also available that achieves 100% paper-based packaging by packing products in paper trays inside cartons. This solution is based on long-established knowhow that has already been proven in other applications in our portfolio. The whole technological process has been developed 100% in-house.

Customize your experience with our cartoners

Choose the horizontal cartoning machine that best suits your requirements for packaging trays in cartons. All IMA cartoners guarantee delicate product handling and reduce any risk of product damage.

The expertise IMA has gained over the years in this sector has led to the development of a vast range of solutions in terms of the feeding systems and ancillary units that can be installed, and the carton sizes and speeds that can be achieved.

Guaranteed Traceability

Labelling and serialisation are essential for avoiding counterfeit pharmaceuticals and guaranteeing the traceability of every single product in a supply chain.

To help you meet this pharmaceutical requirement, IMA Life is always at your side with its vast experience in designing and producing labelling machines. Contact our experts and discover numerous flexible and customised solutions for packaging lines.

From wrap-around to side or top loading

Whatever type of case packer you are looking for, IMA is at your service. From wrap-around to side or top loading, all our models are designed to offer ergonomic operation and easy access for cleaning and maintenance while also ensuring a reduced footprint. Our case packers are also devised to transport and protect products as well as any data that is invisible to the end consumer. This data is essential for combatting counterfeiting and facilitating product tracking at arrival and distribution points.

All our case packers can be stand alone or easily integrated with palletizing solutions in a highly compact structure.

Flexible solutions in smart dimensions

Available in several versions ranging from basic applications, like manual pallet loading, to more sophisticated solutions, such as automatic empty pallet feeding and full pallet unloading, IMA palletizers have a robust structure and use precise, rapid multi-axis robotized systems to position products on pallets with extreme accuracy.

Our range includes integrated case-packing and palletizing solutions in compact structures with highly effective pallet handling thanks to our latest generation robot technology.

Relive

Achema

The exclusive tech videos shot during Achema 2024 are now available on our dedicated website