Ampoule Processing

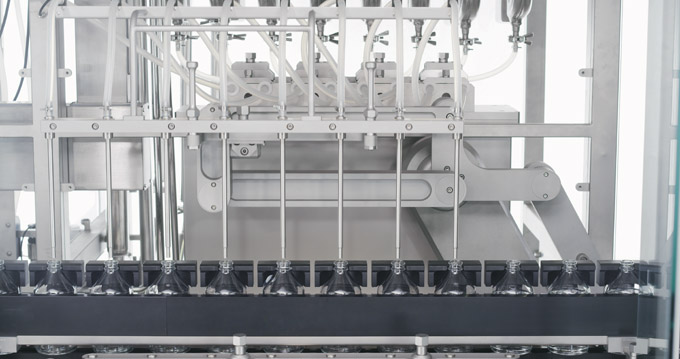

STERIFILL ampoule filling and sealing machine is a linear filler suitable to process 4, 6 or 8 ampoules at each machine cycle, according to the output required.

The machine has been designed following the criteria typically needed in aseptic environments, such as, reduced dimensions, the geometry facilitating the unidirectional airflow, high ergonomic level, slim design.

STERIFILL ampoule filling & sealing machine constitutes the core of fully integrated processing lines. IMA Life design and develop complete aseptic processing lines, starting from ampoule washing and de-pyrogenating, through filling & sealing, up to the final labelling and secondary packaging of the product.

Not a Drop More. Not a Drop Less

In addition to maintain the necessary aseptic conditions, is essential to ensure that the liquid inside the vials is filled with extreme precision and, possibly, in the shortest possible time, so as to guarantee high production speeds.

In order to fully meet these requirements, IMA Life has recently mounted on Xtrema LV, In-line Filling & Stoppering machine, the Micro Motion mass flowmeter provided by Emerson Process Management.

It’s a five-year engagement.

The heart of the innovative solution that allowed IMA Life to get astonishing results in terms of filling range, accuracy and repeatability in the dosing of pharmaceutical liquids can be attributed to the Micro Motion mass Flowmeter supplied by Emerson Process Management, whose staff has worked with the R&D Department of Company in a development process lasted five years.

Relive

Achema

The exclusive tech videos shot during Achema 2024 are now available on our dedicated website