Quick access to IMA Sectors:

Pharma | Food & Dairy | Confectionery | Tea & Beverage | Coffee | Personal & Home Care | Tissue & Nonwoven | Automation | Tobacco | E-Commerce |The Prexima challenge. Comparison of rotary tablet presses seminar in Leverkusen (Germany).

Federica Giatti, Compression Technologist at IMA Active Fabriano Ferrini, Product Manager for tablet presses at IMA Active |

1. Introduction

Troubleshooting is a form of problem solving, often applied to repair failed products or processes on a machine. It is a logical, systematic search for the source of a problem in order to solve it, and make the product or process operational again.

Tablet compression is a science and an art, and a host of factors contributing to a successful product run. Troubleshooting is certainly a critical point on tableting; some of the main problems that manufacturers experience, including insufficient tablet hardness, inconsistent tablet weight, incorrect flow of formulation through the feeding system can often be corrected by making adjustments to the tablet press or its systems. [1]

Loading in dies is one of the most critical part during tableting, choosing the most robust feed frame design and settings of die-filling ensures flexibility on tableting output and moderate possible process drifting. Problems such as weight and hardness variation, segregation, lamination, capping and sticking can be controlled if die filling is reproducible and in a state of control.

In an ideal tableting process, powders should be free flowing, characterized by particles with a narrow range of particle size distribution, cohesive enough to hold and stay together but not too much, so that they can adhere to punches and dies surface.

Typically in direct compression approach, some powders show poor flowability, high value of moisture content thus limiting the free flowing in dies occurring troubles such as weight instability or low production output.

Aim of this study, performed in a contest of competitors comparison, was optimizing feed frame design and tableting process parameters to increase die-filling uniformity for a poor flowable powder on an industrial rotary tablet press (Prexima 300, IMA).

2. Materials and methods

Lactose based blend was used as a poorly flowable model formulation providing two type of lactose, a finer one (GranuLac 200, Meggle) and a coarser one (Tablettose 70, Meggle) and magnesium stearate (Ligamed MF-2-V, Peter Greven) as lubricant (Table 1).

| Compounds | Content (%) |

| Granulac 200 | 74.0 |

| Tablettose 70 | 24.5 |

| Ligamed MF-2-V | 1.5 |

Table 1: qualitative and quantitative formulation of poor flowable powder.

The blend was technological analyzed in terms of flowability (Carr Index), L.O.D and particle size distribution. Carr Index resulted 28 (corresponding to a poor flowable classification), L.O.D. measured at 105°C, was 0.12% and the particle size distribution is characterized as quite inhomogeneous (Graph 1).

Graph 1: particle size distribution of the model formulation.

The scope of the study was maximizing force-hardness profile (trial 1), minimizing Relative Standard Deviation (RSD, %) on weight (trial 2) and maximizing output (trial 3) focusing always on tablet weight RSD for the poor flowable powder described.

Trials conditions were performed in a contest of competition among tablet presses manufacturer: competitors were five and each one must compete in same equipment condition; for this reason tests were decided in advance from the competition organizer and can be summarized as:

• Trial 1: medium tablet press speed, four main compression pressure levels (50, 100, 200, 300 mPa) and no pre-compaction force;

• Trial 2: medium and fast tablet press speed, tablet hardness between 800-100 N and no precompaction force;

• Trial 3: no limitation even on tablet press speed than on pre-compaction force, but tablets should be characterized by a tablet strength between 800-100 N with, at maximum, 2% as weight RSD.

Equipment and tooling mandatory to be used in this comparison contest were standard dies Euro-BB standard punches Euro-B with round shape, diameter 8 mm and radius of curvature of 12 mm. IMA chose rotary tablet press model Prexima 300 equipped with 41 stations and tooling condition given by the context.

Concerning feeding system, fill cam and hopper, each competitor was able to use best conditions.

3. Results and discussion

Choosing the best feeding system with blend dedicated-paddle shape played a key-role for hitting the target required. The different machine setting, process parameters and paddles shape has been evaluated based on RSD (%) on main compression force and tablet weight.

First preliminary trials were performed in standard conditions (standard feeder with two flat paddle profile) but no benefits were observed. Consequently, a three-paddle feeder was mounted to load the lactose-based blend, showing evident improvements.

Once feeding system type was identified, different paddle shape have been analyzed: it is important to distinguish the function of each of the paddles inside the feeder; in particular the paddle on the left is more responsible for powder loading in dies, instead the one on the right is responsible for die filling control. The additional one (third paddle) delivers smoothly the powder during hopper flowing.

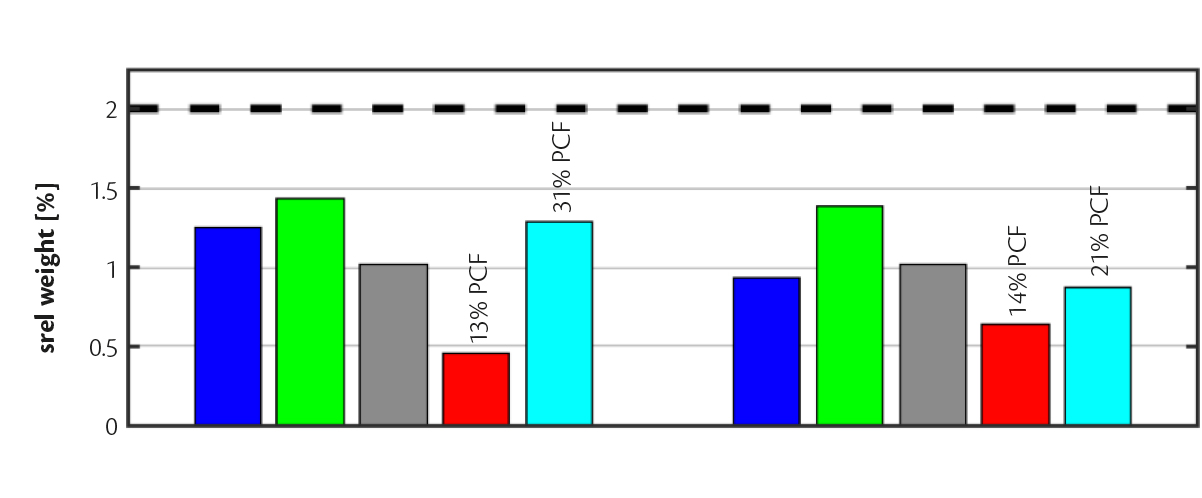

Figure 2: all-in graphs of weight RSD (%) obtained for trial 1 (on the left) and trial 2 (on the right) for all competitors.

Figure 2: all-in graphs of weight RSD (%) obtained for trial 1 (on the left) and trial 2 (on the right) for all competitors.

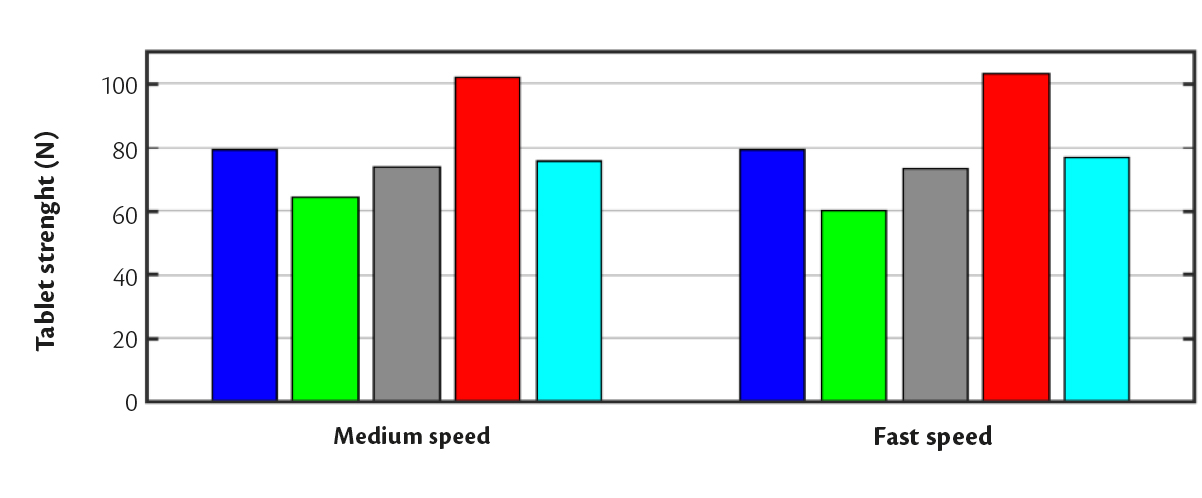

Figure 3: all-in graphs of tablet strength (N) obtained for trial 1 (on the left) and trial 2 (on the right) for all competitors.

Figure 3: all-in graphs of tablet strength (N) obtained for trial 1 (on the left) and trial 2 (on the right) for all competitors.

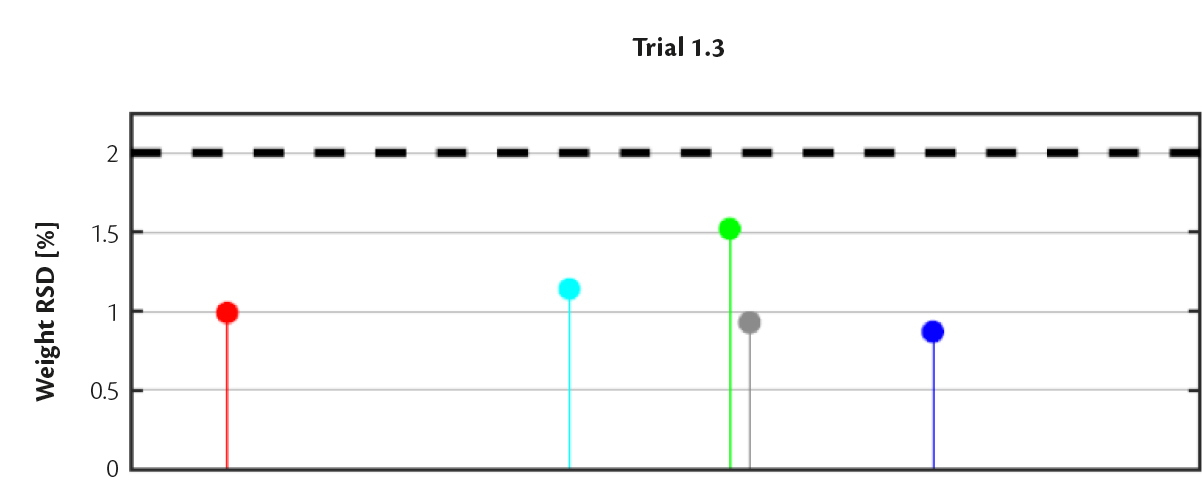

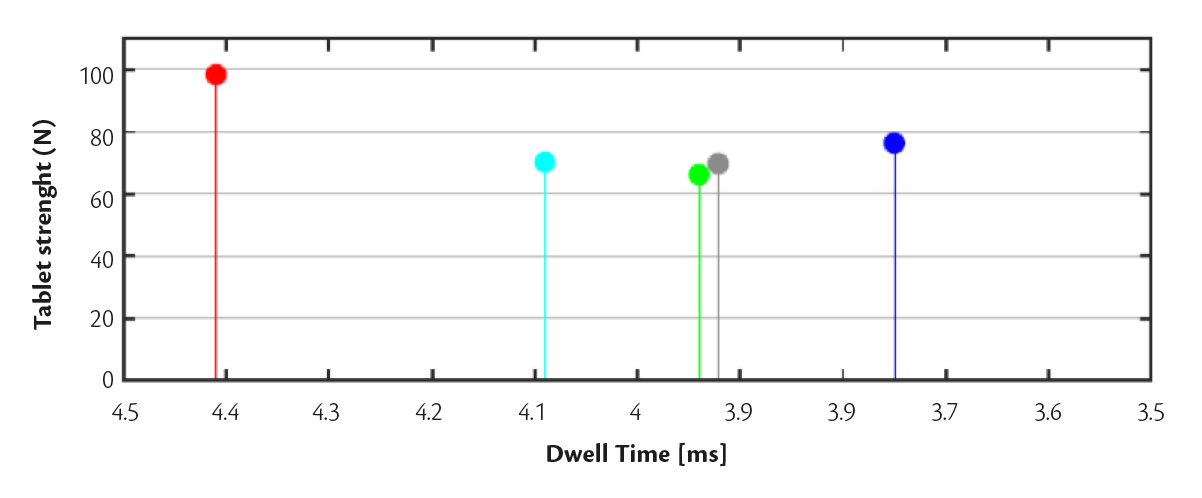

Figure 4: all-in graphs of weight RSD (%) obtained for trial 3 (on the top) and of tablet strenght (on the bottom) for all competitors vs dwell time.

Figure 4: all-in graphs of weight RSD (%) obtained for trial 3 (on the top) and of tablet strenght (on the bottom) for all competitors vs dwell time.

Combining different paddles profile and studying the influence on tablets’ quality, feed frame design defined was round off-set with reduced rods on the left, flat slanted on the right and round off-set as third paddle. [3]

To evaluate the result obtained, Relative Standard Deviation on weight and tablet strength were evaluated for trial 1 and 2.

In both cases, Relative Standard Deviation was the lowest one, compared to competitors’ results; this confirm that the combination between feeder and paddle shape was the goal to achieve best result (Figure 2, IMA result in red).

The same approach for tablet hardness: IMA was able to obtain the highest one compared to the same trial condition (Figure 3, IMA results in red).

The results obtained explained that IMA tablets (designed in red) had the highest density possible as well as the lowest Relative Standard Deviation on weight: this is strictly connected to the feeding capability because dies loading is maximized and improved at its best improving, at the same time, final quality of tablets.

Aim of trial 3 was maximizing the output without affecting the quality of the tablets (Figure 4). Basically, all competitor were able to reach tablet press speed between 92% and 100% of the nominal output achieving, at the same time, the hardness required and maintaing a RSD% on weight under the 2%.

These graphs show, respectively, RSD (%) on weight (on the top) and tablet strength (on the bottom) compared to the dwell time: again very low Relative Standard Deviation on weight with highest tablet strength, confirming the perfect filling of the blend inside the dies (IMA results in red).

Dwell time corresponds to the time of the flat part of punches head under compression roller, it is the main responsible of the hardness given to the tablets. It is calculated thanks to this equation:

Dwell time (ms) = (L ∙NS∙3600)/(π∙PCD∙TPH)

Where L is length of flat portion of punches head (mm), NS is number of stations, PCD is pitch circle diameter of the turret (mm) and TPH represents tablet per hour produced.

4. Conclusions

Poor flowable blend was successfully compressed at its best, improving process parameters and machine settings: in particular, thanks to feed frame profile optimization, die-filling uniformity was increased and process became robust and reproducible. Additionally, tablet press output was maximized maintaining tablets’ quality within desired range with enhanced density. Three paddle feeder with customized paddle profile is the linchpin to achieve the goal.

Paper Sections

Last Submitted Papers

- How to perform a good scale-up

- Development of an automated multi-stage continuous reactive crystallization system with inline PATs for high viscosity process

- Prexima 300. Determination of the effect of the pre-compression force on the tablet hardness, obtained at constant value of the main compression force

- FMECA Risk Analysis background for calibrated containment solutions