When therapies require smaller volumes and employ a greater number of different products manufactured in medium-to-low production batches, flexible production methods are essential.

INJECTA responds to this need for a high degree of flexibility.

When therapies require smaller volumes and employ a greater number of different products manufactured in medium-to-low production batches, flexible production methods are essential.

INJECTA responds to this need for a high degree of flexibility.

INJECTA. The future of aseptic processing.

The use of advanced robotic-driven manipulations versus conventional handling systems actually improves product quality and manufacturing efficiency.

INJECTA handles pre-sterilised Ready-To-Use containers (syringes, vials or pre-capped cartridges), pre-oriented vials in trays as well as sterilised vials from the depyrogenation tunnel, allowing high process flexibility and adaptability.

Specialised robots perform all handling activities with no glass-to glass contact and without operator intervention. Result is “less time” spent validating aseptic conditions and superior agility for multi-product manufacturing.

INJECTA Highlights

INJECTA 36 VERSION

INJECTA 36

Enhancing the performance of advanced robotics, the INJECTA 36 raises the bar for high-speed production of Ready-To-Use syringes and pre-capped cartridges. The same cutting-edge robotic technologies assure accurate no-touch-transfer component processing with minimal operator access to the working area.

Introducing an innovative solution for 100% In-Process Control and check-weighing, INJECTA 36 consolidates IMA Life as a key player in the Ready-To-Use segment for automatic filling & closing machines to maximise production performance.

- Technical Data

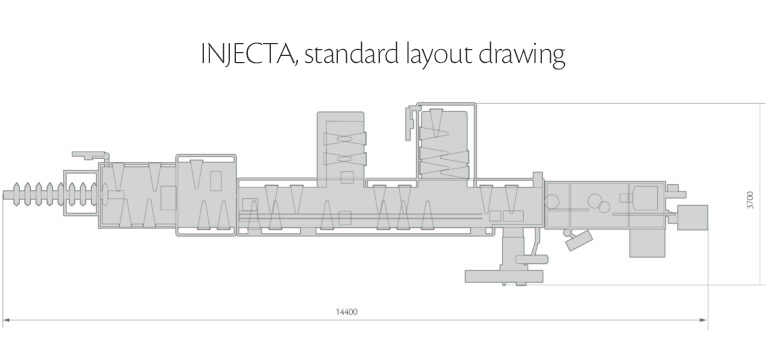

- Machine Layout

| FEATURES | INJECTA FAMILY | ||

| INJECTA 6 | INJECTA 10 | INJECTA 36 | |

| Automation | Fully robotic automated | Fully robotic automated | Fully robotic automated |

| Footprint | 6,100 x 3,600 x 2,080 [L x W x H] | 7,200 x 4,500 x 2,080 [L x W x H] | 3,400 x 2,050 x 2,080 [L x W x H] |

| In-Process Control | 100% at full speed | 100% at full speed | 100% |

| RTU vial dimensions | Ø 16 – 42.4 mm | Ø 16 – 42.4 mm | Ø 16 – 42.4 mm |

| Output vials | up to 4,800 pcs/h | up to 12,000 pcs/h | up to 18,000 pcs/h |

| RTU syringe dimensions | 0.5 – 20 ml | 0.5 – 50 ml | 0.5 – 50 ml |

| Output syringes | up to 4,000 pcs/h | up to 12,000 pcs/h | up to 36,000 pcs/h |

| RTU cartridge dimensions | 1 – 20 ml | 1 – 20 ml | 1 – 20 ml |

| Output cartridges | up to 3,600 pcs/h | up to 10,800 pcs/h | up to 18,000 pcs/h |

| Suitable for high potent | Yes | Yes | Yes |

| Loading from depyrogenation tunnel | Yes | Yes | No |