By embracing new robotic technologies adopted throughout all production operations, from outer/inner bag opening to the downstream handling process, IMA LIFE solutions enable a very smooth production process, reducing cross-contamination risks.

By embracing new robotic technologies adopted throughout all production operations, from outer/inner bag opening to the downstream handling process, IMA LIFE solutions enable a very smooth production process, reducing cross-contamination risks.

Robots do it better, it’s a clean-cut fact.

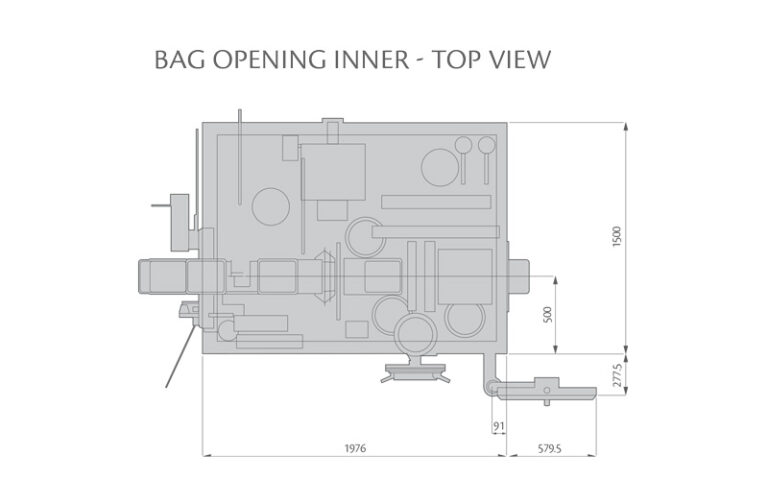

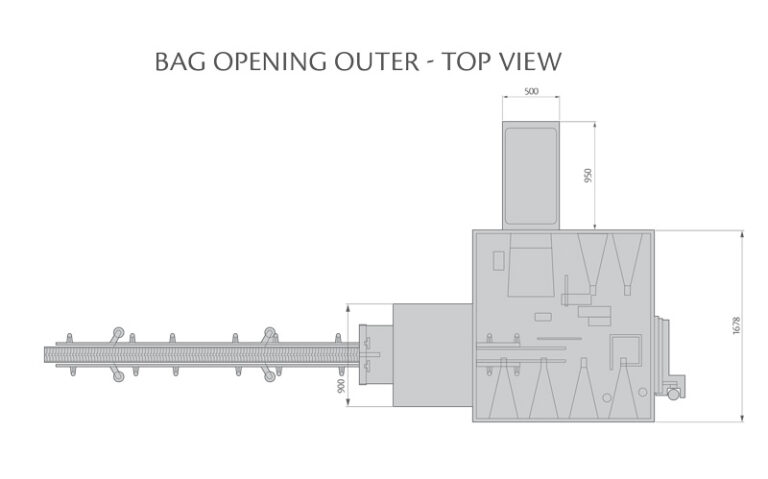

The primary package feeding area is usually surrounded by an open RABS (in the case of the outer bag opening module) or a closed RABS (in the case of the inner bag opening module), separating the nearby isolated processing area.

After a pincer device performs pick-up, the overwrapped tub/tray is automatically transferred to the cutting station, where the overbag is opened by a robotic cutting arm.

In case the primary package is supplied in a double-bag configuration (inner + outer bag solution), a double-cutting station is installed. The cut is made while keeping the bag flaps in a closed and fixed position.

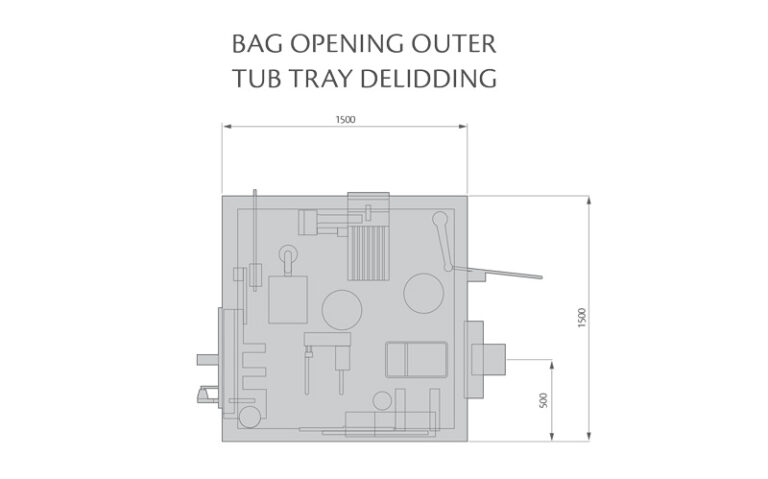

After cutting, the package is instantly transferred by an internal transfer port to the isolated, processing area where the tub/tray will be definitively opened at the de-lidding station.

BAG OPENING AND TUB/TRAY OPENING Highlights

- Machine Layout