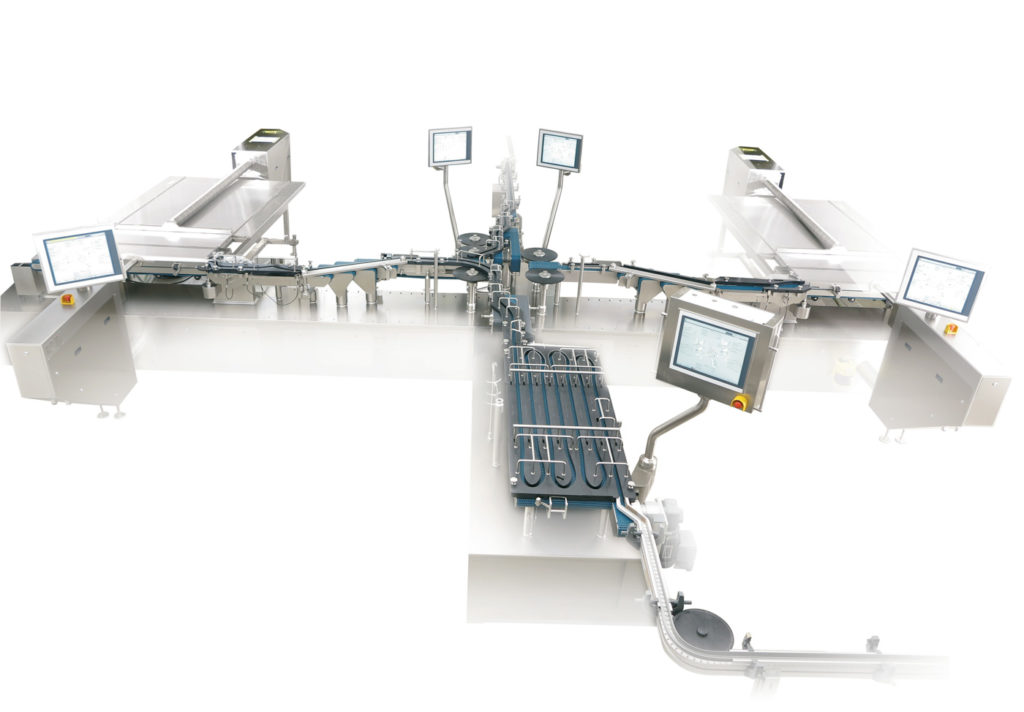

Freeze Drying Loading & Unloading Systems

Automatic Loading and Unloading Systems Increase Efficiency and Reduce Contamination Risks

Automatic Loading and Unloading Systems Increase Efficiency and Reduce Contamination Risks

Automatic Loading and Unloading Systems Increase Efficiency and Reduce Contamination Risks

Automatic Loading and Unloading Systems minimize the risk of contamination through human intervention in the loading and unloading of freeze dryers. The amount of product handled when using an automated loading and unloading process is increased since the time spent for the loading/unloading operation is, of course, much shorter if compared to manual loading.

Operational costs are also reduced since these state-of-the-art systems drastically decrease the number of operators needed to assist the freeze drying process. In some cases, the machine can be left unattended, as well. As a consequence, the SAL levels are greater while contemporarily reducing the operating costs.

The protection of operators also when handling potent compounds can be achieved with these automated systems, since they can be installed either under closed R.A.B.S. or even under a proper isolator.

• The request to install automated loading systems for freeze dryers dates back to the early 80’s when the pharmaceutical industry in both USA and Europe was the main contractor.

• More than 150 machines are currently installed and working in western countries; USA are the major users with more than 65% of the equipment installed.

• Nowadays, the pharmaceutical industry in the so called emerging countries is more and more requesting the use of automated systems and the main drivers for that are the new chinese cGMP and the increasing levels of drugs exports to regulated markets. The above drives all new Lyo plants into Auto-loading which is foreseen to double in the next 2-3 years.

The IMA LIFE automatic loaders ensure efficient, safe and reliable performances thanks to the following key features:

- Extremely compact footprint

- High throughput with loading speed up to 600vpm

- High flexibility to handle different vial size parts

- Quality sanitary design – vhp (h2o2 vapour) compliant

- Pre-arranged for uaf; closed rabs and isolator application

- Excellent integration with freeze dryers