Quick access to IMA Sectors:

Pharma | Food & Dairy | Confectionery | Tea & Beverage | Coffee | Personal & Home Care | Tissue & Nonwoven | Automation | Tobacco | E-Commerce |UNIVERSA

Designed specifically to offer high flexibility in wrapping, UNIVERSA can handle from single roll to any other multi-rolls configuration, wrapped with any flexible plastic or paper material, transparent or printed.

Designed specifically to offer high flexibility in wrapping, UNIVERSA can handle from single roll to any other multi-rolls configuration, wrapped with any flexible plastic or paper material, transparent or printed.

Get the best of the wrapping technologies.

From TMC expertise in wrapping technologies, UNIVERSA is the automatic wrapping machine for bathroom tissue and household towel rolls that joins the maximum flexibility and versatility with high production performance and ease of use.

Combined to the converters of tissue products, UNIVERSA can wrap single, double and triple layer packs at high speed (up to 200 packs per minute), with rolls placed both in horizontal and in vertical position. It can also pack single bathroom tissue or household towel rolls up to 50-60 BRT rolls and 20 HHT rolls pack configurations.

An innovative tutoring system is installed in the control panel and guides the operator step by step, helping his efficiency. The control panel also guides change-over operations for an easy management of the machine.

UNIVERSA can store recipes for fast, accurate and repetitive setting; change-over operations require a reduced number of parts and adjustments which do not require tools.

Sustainability

UNIVERSA has the ability to treat heat-sealable paper, bringing to the market new products packed with eco-sustainable materials in response to a demand for increasingly “green” products.

UNIVERSA Highlights

- Technical Data

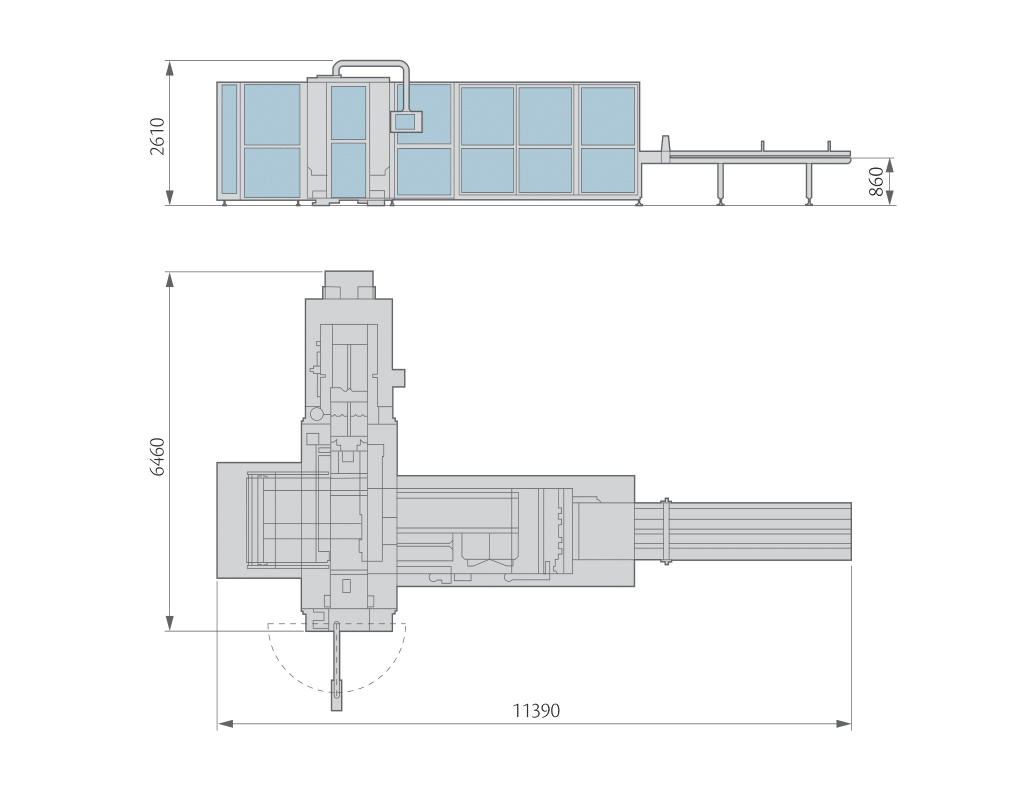

- Machine Layout

| UNIVERSA TECHNICAL DATA | ||

| Max. mec. speed |

up to 220 cy/1′ |

|

| Servo Motors |

20 to 24, depends on possible options |

|

| Infeed Product Range | MIN | MAX |

|

Diameter |

90 mm |

170 mm on 4 lanes; |

|

Cut-Off |

90 mm |

300 mm |

| Outfeed Product Range | MIN | MAX |

|

Width |

90 mm |

600 mm |

|

Depth |

180 mm |

600 mm |

|

Height |

90 mm |

300 mm |

| Poly Capability | MIN | MAX |

|

Reel width |

320 mm |

1500 mm |

|

Repeat length |

225 mm |

850 mm |

|

|

|

* Optional Required

|