Quick access to IMA Sectors:

Pharma | Food & Dairy | Confectionery | Tea & Beverage | Coffee | Personal & Home Care | Tissue & Nonwoven | Automation | Tobacco | E-Commerce |NEXT

Modern shopfloors need to quickly change products, even every week, in order to satisfy the various market requests. Speed and minimum machine stops are crucial: NEXT answers these needs, introducing reproducible settings and shorter cleaning duration.

Modern shopfloors need to quickly change products, even every week, in order to satisfy the various market requests. Speed and minimum machine stops are crucial: NEXT answers these needs, introducing reproducible settings and shorter cleaning duration.

No compromise on speed.

NEXT by IMA TEKNOWEB is the ultimate high-speed platform for length fold wipes, delivering top efficiency and minimal downtime.

Featuring advanced LAP “zero speed” splicing and premium tension control, it handles any roll type with ease.

Proprietary cutting technology achieves up to 1000 cuts/min, while up to 3 flow wrappers maximize output. With stainless steel rotating blades and over 95% production efficiency, NEXT sets the standard for reliability and safety in wipes converting.

Sustainability

Next can process raw materials with low (or even zero) environmental impact, compared to the standard wipes composed of PP, PE or viscose. The sustainable material handled by Next is composed of cellulosic fibers derived from wood pulp.

NEXT Highlights

Product output options preview

- Technical Data

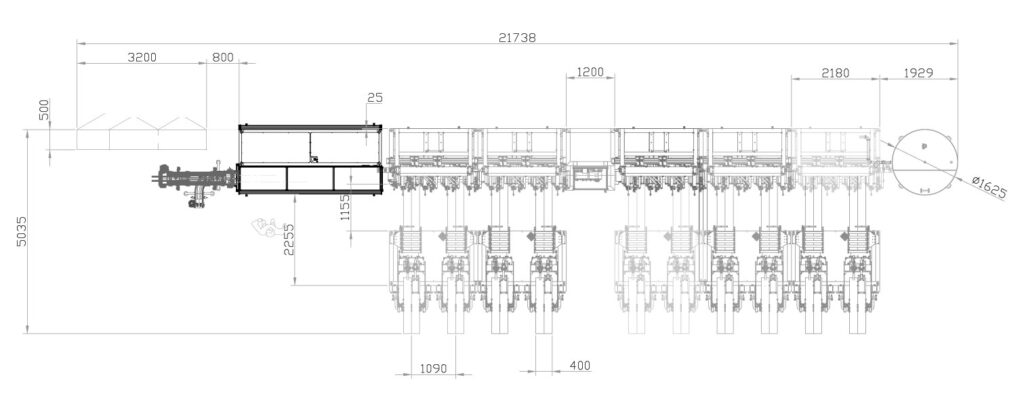

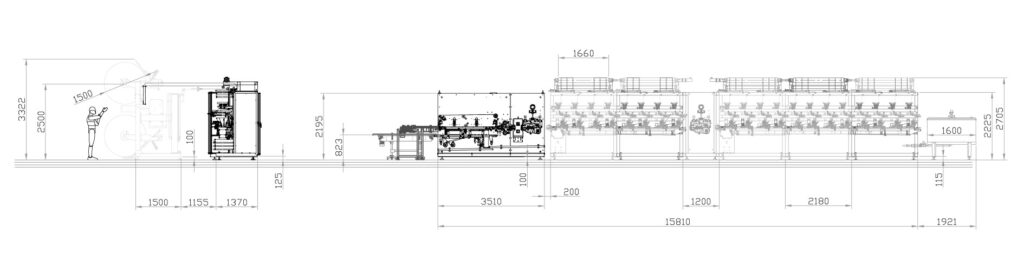

- Machine Layout

| NEXT | |

| Design speed (wipes/min) | up to 24.000 |

| Operating speed (wipes/min) | up to 21.600 |

| Cutting speed (clips/min) | up to 1000 |

| Stacking speed (stacks/min) | up to 300 |

| Linear speed (m/min) | up to 200 |

| Number of lines | up to 25 |

| Drive system | Full servo |

| Roll diameter (mm) std | opt | 1200 | 1500 |

| Pre-cut reels width (mm) min | max | opt | 130 | 210 | 400 |

| Semi-jumbo roll (mm) min | max | 800 | 1200 |

| Cutting technology | Pinch die cut |

| Stack length (mm) min | max | opt | 100 | 230 | 400 |

| Web centering device | Yes |

| Folded wipe width (mm) min | max | opt | 80 | 140 | 160 |

| Reels splice | Automatic, zero speed |

| Interfolded | Yes NO |

| Fold type | Z, C, W, modified V |

| Clip height (mm) min | max | 5 | 25 |

| Stack height (mm) min | max | 5 | 80 |

| Count min | max | 12 | 120 |

| Quantity of lotion(%) min | max | 200 | 400 |

| Efficiency (%) pre-cut rolls | semi-jumbo | > 90 | > 95 |

| Waste (%) | < 3 |