Quick access to IMA Sectors:

Pharma | Food & Dairy | Confectionery | Tea & Beverage | Coffee | Personal & Home Care | Tissue & Nonwoven | Automation | Tobacco | E-Commerce |GENESIS

GENESIS is a wet & dry wipe converting line extremely reliable and effective, suitable for start-ups in the field, limited budget projects or for small lots productions but still demanding a high-quality finished product.

GENESIS is a wet & dry wipe converting line extremely reliable and effective, suitable for start-ups in the field, limited budget projects or for small lots productions but still demanding a high-quality finished product.

The wipe converter for your needs.

GENESIS is a length-fold wet & dry wipes converting line that can handle from 6 to 12 pre-cut rolls with manual or automatic splice for maximum flexibility and easiness of use.

In its “dry” version, it can produce wipes with standard fabrics, allowing the customer to produce a wide range of products on the very same line. For more specific fabrics the converter can be set up with dedicated features, to cope with raw material low basis weight and lack of adhesion between layers. These products include color catcher sheets or softeners sheets among the others.

Regarding the “wet” version, it comes complete of everything for a piece-of-mind project: sanitary lobe pump, electronic flowmeter, service tank with level sensors, CIP ready, equalizer pressing belt. Machine is also provided with high-speed and long lasting rotary die-cutter, with reliable blades in stainless steel that can cut up to 300mm length wipes.

GENESIS can be provided compliant to ATEX (explosion-proof) standards, to safely produce and handle wet wipes soaked in Isopropyl Alcohol (IPA) or any other flammable liquids.

It complies with the sanitary standards accepted worldwide, reducing risks of product contamination. All the equipment allow easy and effective CIP (Clean In Place) so that formula-change can be done quickly. This is the reason why Genesis is the preferred choice to produce small lots and with multiple changeover in a day.

It can include an integrated flow wrapper, tailored to perfectly match maker features and performance.

GENESIS Highlights

Product output options preview

- Technical Data

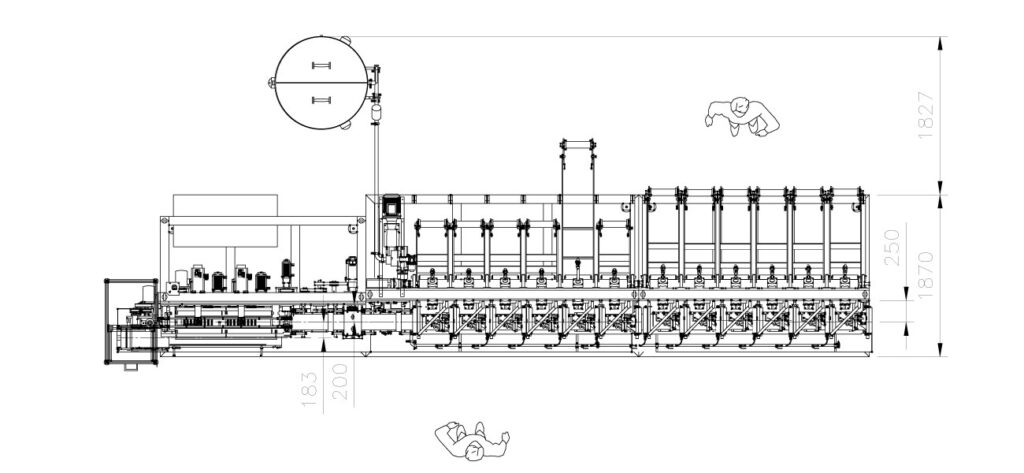

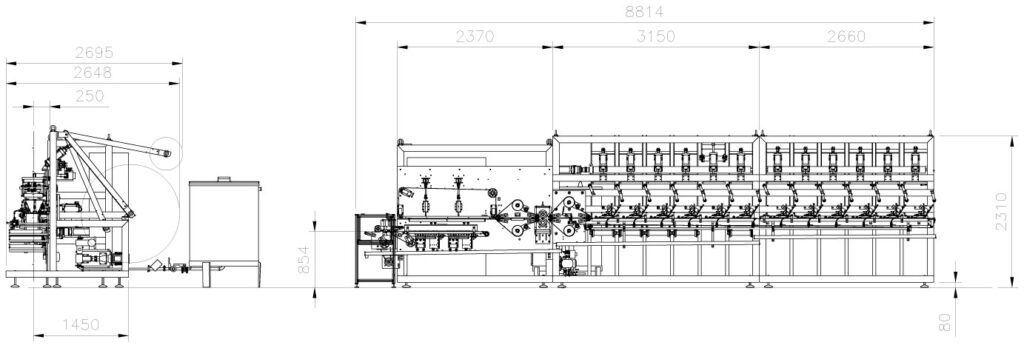

- Machine Layout

| GENESIS 10 | GENESIS 12 | |

| Design speed (wipes/min) | up to 6000 | up to 7200 |

| Operating speed (wipes/min) | up to 5000 | up to 6000 |

| Cutting speed (clips/min) | 500 | 500 |

| Stacking speed (stacks/min) | 120 | 120 |

| Linear speed (m/min) | 100 | 100 |

| Packing machine speed (packs/min) | 100 | 80 with gusset | 100 | 80 with gusset |

| Rolls – Precut | 10 | 12 |

| Drive System | Full Servo | Full Servo |

| Roll diameter (mm) std | opt | 1200 | 1500 | 1200 | 1500 |

| Roll width (mm) min | max | opt | 150 | 250 | 290 | 150 | 250 | 290 |

| Stack length (mm) min | max | 100 | 320 | 100 | 320 |

| Folded wipe width (mm) min | max | 75 | 120 | 75 | 120 |

| Interfolded | Yes | No | Yes | No |

| Fold type | Z, C, W, modified V | Z, C, W, modified V |

| Reels splice std | opt | Manual | Automatic | Manual | Automatic |

| Clip height (mm) min | max | 5 | 20 | 5 | 20 |

| Stack height (mm) min | max | 5 | 80 | 5 | 80 |

| Quantity of lotion (%) min | max | 200 | 350 | 200 | 350 |

| Labelling machines std | opt | 2 | 3 | 2 | 3 |

| Sealing of wrapping machine film | Automatic | Automatic |

| Sealing head | Long Dwell Technology | Long Dwell Technology |

| Waste (%) | < 3 | < 3 |