Quick access to IMA Sectors:

Pharma | Food & Dairy | Confectionery | Tea & Beverage | Coffee | Personal & Home Care | Tissue & Nonwoven | Automation | Tobacco | E-Commerce |FACE 400 Series

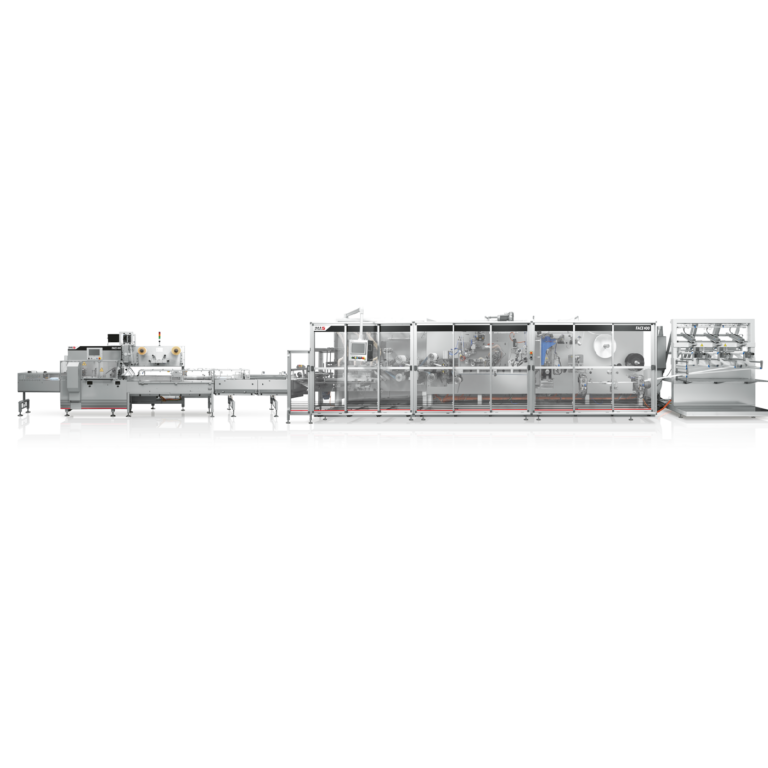

Converting and flow wrapping line designed for the manufacturing of surgical face masks and FFP2/3 or N95 class respirators. A concentrate of technologies suitable for the processing of different materials to ensure maximum flexibility.

Converting and flow wrapping line designed for the manufacturing of surgical face masks and FFP2/3 or N95 class respirators. A concentrate of technologies suitable for the processing of different materials to ensure maximum flexibility.

Technology that cares.

Thanks to its wide experience in the nonwovens industry, Teknoweb Converting stands as reliable partner for the manufacturing of converting lines for face masks and respirators, ensuring high performance combined to extreme sanitary design.

The machine range includes two models:

- FACE 400 – converting solution for surgical face masks

- FACE 400D – converting solution for FFP2/3 or N95 class respirators

As main contractor for full manufacturing lines, downstream the converting machines Teknoweb can provide the most suitable solution for packing the finished products: this line can be completed by IMA’s modular flow wrapper or integrated carton box, designed to handle face masks and ideal for the integration into complete lines thanks to an easy plug&play solution.

FACE 400 Series Highlights

IMA FACE 400 versions

Complete solution for surgical face masks.

IMA FACE 400 mask converter is a turn-key solution for surgical face masks.

The converting unit is based on a well consolidated platform, widely used to convert products made by lamination and welding of different fabric webs by hot melt or ultrasonic sealing. The unit is able to produce surgical masks in 3 layers, with nose clip and elastic threads. FACE 400 allows to use all type of elastics as polymeric, textile, round, squared, providing ultimate flexibility in product design. Layers are welded together by ultrasonic system to give a nice and well defined profile pattern.

The packaging unit can be a modular flow wrapper designed to handle surgical masks. Ideal for integration into complete lines thanks to an easy plug&play solution, it can also be provided with a manual feeding system for a stand alone application. This platform is available in different configurations aimed to handle any size of mask.

FACE 400 is capable to run up to 200 packs per minute with a single mask, stacking from 1 to 15 pieces.

Easy machine cleaning and accessibility are guaranteed according to the latest design standards. The line can be also equipped with an integrated cartoner for primary or secondary packaging solutions.

Converting and packing platform for FFP2/3 or N95 respirators.

FACE 400D is the evolution of its forerunner and is able to convert foldable, flat respirators in FFP2/3 or N95 class in 3 panels style with head-band elastics.

This specific respirator is the most used as PPE in professional environments and is the most convenient and comfortable when worn for long. It can run up to 300 pieces per minute. A module to apply in-line exhalation valves is available.

Respirators are ultimately wrapped individually and can be packed in carton boxes in one integrated solution, requiring only one operator and one partial support for raw material loading.

- Technical Data

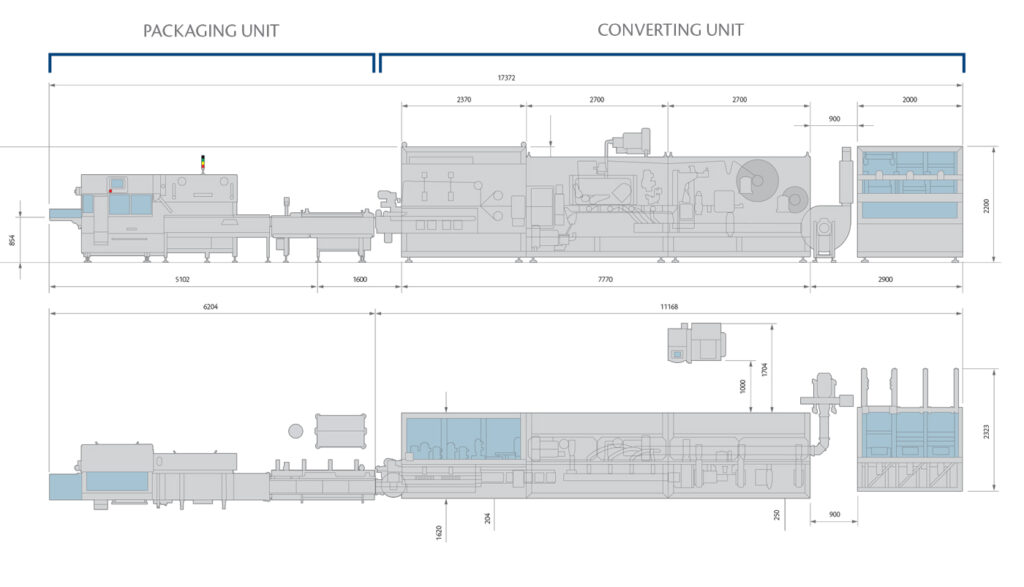

- Machine Layout

| FACE 400: converting unit technical data | |

| Machine Speed | from 200 to 400 ppm (pieces per minute) |

| Mask dimensions | 200mm length x 100mm width (standard) Different sizes available on request. |

| Mask Materials | 3 filtering layers: 2 layers of spun-bonded on upper and lower edges – 1 layer of Melt Blown in central area. The unit is capable of handling different materials upon request. |

| FACE 400: packaging unit technical data | |||

| Machine Speed | Up to 200 cpm with single mask. Production output dependent upon product, film and machine specifications | ||

| Maximum mask size | Length

250mm |

Width

110mm |

Maximum stack height

65mm |

| Stacks | From 1 to 40+ pieces in a box, from 3/5 up to 15 in a flow pack. | ||

| Wrapping materials | Suitable heat-sealable films, such as plain, or co-extruded polypropylene (PP), laminate films (e.g. OPP+PE), polythene films (PE) as well as cold sealable films of suitable quality | ||

| FACE 400D: Converting unit technical data | |

| Machine speed | Up to 300 ppm (pieces per minute) depending on raw materials and respirator configuration. |

| Mask dimensions | 210 mm length x 90 mm width (standard) Different sizes available on request |

| Mask materials | Up to 5 filtering layers: 2 layers of spun-bond on upper and lower edges, 1-2 reinforcement layers of flatbond – 1 or 2 layers of Melt Blown in central area. The unit is capable of handling different materials upon request. |

| Face 400D: Packaging unit technical data | |||

| Machine speed | Up to 300 cpm with single respirator in a pouch. Production output dependent upon product, film and machine specifications. | ||

| Maximum mask size | Length

250 mm |

Width

110 mm |

Maximum stack height

65 mm |

| Stacks | From 1 to 20+ pieces | ||

| Wrapping materials for pouch packing | Suitable heat-sealable films, such as plain, or co-extruded polypropylene (PP), laminate films (e.g. OPP+PE), polythene films (PE) as well as cold sealable films of suitable quality. Rigid thin carton, glued on line |

||