IMA TMC: Decades of experience in the tissue primary and secondary packaging, at your service.

For over 20 years, IMA TMC has been offering the most innovative solutions to handle and solve the complexities related to the packaging and handling of Tissue and Personal Care products.

Our range of wrappers, bundlers and palletizing systems are among the most appreciated by the market for their speed, precision and flexibility.

-

WRAPPING

-

BUNDLING

-

PALLETIZING

WRAP250 - The fastest wrapper on the market

WRAP250 is the answer to the need of a high-speed single to multi-roll wrapper for tissue products.

This machine overcomes up to 25% the market average maximum capacity of packs per minute, requiring only a single packaging line to produce up to 1000 rolls per minute, avoiding production limitation for rewinders.

The Smart Overhead trolley allows continuous motion transfer during folding, while the Push-Pull technology leaves only one finger set between two packs.

The Never-Stop Technology, embedded in WRAP250, checks the correct rolls configuration immediately before the elevator, identifying any rolls that are:

- out of shape (tail)

- out of position (tipped)

- incorrectly launched (missing or extra count) inside the flying bar

Without any operator intervention, the non-compliant configurations are discarded and replaced with new ones without stopping the machine.

UNIVERSA - Flexibility at hand

From IMA TMC expertise in wrapping technologies, UNIVERSA is the automatic wrapping machine for bathroom tissue and household towel rolls that joins the maximum flexibility and versatility with high production performance and ease of use.

Combined to the converters of tissue products, UNIVERSA can wrap single, double and triple layer packs at high speed (up to 200 packs per minute), with rolls placed both in horizontal and in vertical position. It can also pack single bathroom tissue or household towel rolls up to 50-60 BRT rolls and 20 HHT rolls pack configurations.

An innovative tutoring system is installed in the control panel and guides the operator step by step, helping his efficiency. The control panel also guides change-over operations for an easy management of the machine.

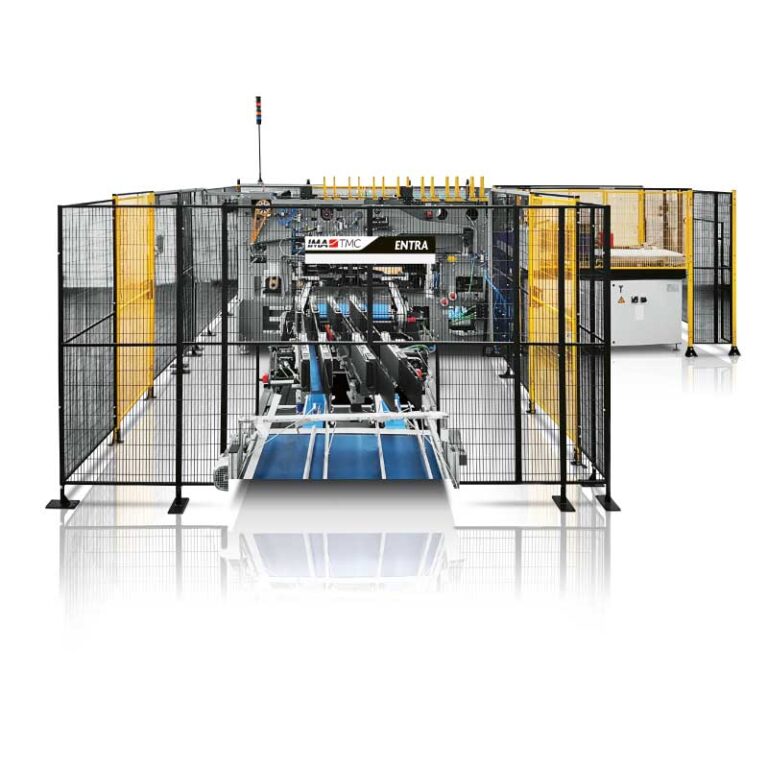

ENTRA - Your AFH partner

ENTRA is the automatic wrapping machine for bathroom tissue and household towel rolls, away from home rolls (AFH) and medical tissue rolls (MT), designed and manufactured for medium capacity production lines.

This machine guarantees an efficient production capacity thanks to the performance of the innovative infeed diverter unit. The group is designed to pack a wide range of AFH rolls, allowing extremely flexible handling depending on the products to be treated.

Thanks to its ease of use, ENTRA allows a significant reduction in format changeover times, minimizing skills required to the operators. The integrated Integrated Electrical Cabinet leads to an important layout saving.

ENTRA with its innovative design solutions, guarantees high performance combined with unique flexibility in the packaging market.

SUPERA - Single by choice

SUPERA is a single roll packaging machine revolutionizing bath and kitchen towel roll wrapping. With innovative technologies and brushless servomotors, SUPERA achieves unprecedented speeds of up to 250 packs/minute in polyethylene, polypropylene, and paper wrapping.

Its modular tuck group option ensures rapid and precise operations. Easy management is facilitated through the intuitive touch screen control panel, enabling quick, accurate, and repeatable settings stored in recipes for seamless performance.

OTTO - Fold it your way

OTTO stands out as the sole wrapper in the market offering three distinctive folding styles:

- Fold & Seal

- Twist & Tuck

- Twist & Seal (for 1-lane pack configurations)

This machine can wrap packs in polyethylene, polypropylene, or paper, contributing to more sustainable packaging solutions. OTTO effortlessly handles single layer pack configurations of 1 or 2 lanes, allowing for seamless automatic operation.

With its intuitive touch screen control panel, OTTO ensures easy management and swift changeovers. Operators can store full size adjustments in recipes, facilitating rapid, precise, and repetitive settings.

XWRAP - Easy and smooth

XWRAP is the advanced automatic wrapping machine for bathroom and household tissue towel rolls. This high-speed servo sequential multi-roll packaging machine handles single- and double-layer formats with ease, using thermo-sealable materials like PE or PPE.

With its user-friendly interface, XWRAP ensures quick changeovers through the intuitive HMI. Operators can easily adjust sizes and save configurations for rapid and precise settings. Its streamlined design reduces downtime, allowing effortless transitions between different pack configurations.

CINQUE

CINQUE is the top range of automatic IMA TMC bundlers, designed for single or any other multi-roll configuration, for bathroom and kitchen products, and with any flexible plastic packaging material, both transparent or printed.

The continuous motion of the production process is guaranteed from the beginning: CINQUE features a pack distributor that sorts the packs as they arrive inside channels, bordered by guides, into the number of rows set by the bag size currently being processed.

CINQUE improves the production capacities of every existing format, while maximising performance in the requested product dimensions. This extremely flexible machine is capable to treat all pack typologies, from single BRT/KT roll to triple layer configurations.

The management of all movements “in electrical axis” is the key to achieve a great level of flexibility and precision of the movements, reducing drastically changeover downtime.

QUATTRO.PLUS

Especially designed to obtain the greatest possible number of roll bundles configurations, QUATTRO.PLUS is an automatic bundler that allows to switch from one bundle format to another quickly, granting maximum flexibility and realiability.

QUATTRO.PLUS features a rotary deviator, adjustable according to product size, so that product size and dimensions are not an issue.

This machine also features a high-end sealing quality: the longitudinal sealer uses a jet of hot air to seal the overlay of the packaging material.

The Human Machine Interface (HMI) through panel PC provides easy machine management and operations. Easy, fast and repeatable format changeover is always guaranteed, as in IMA TMC tradition, thanks to the innovative construction features.

Thanks to the presence of an integrated electrical cabinet, QUATTRO.PLUS requires a rationalized space, still getting the most of its potential.

NEST - ZERO PRESSURE, 50% SPACE REDUCTION

When handling tissue products, it is essential to rely on technologies that allow products palletizing without damages. Traditional compression and suction technologies are ideal when handling products of a certain stiffness, but may not be suitable for handling very delicate or soft products such as bundles of paper rolls. In this sense, IMA TMC has developed the new NEST: a patented layer gripping head solution that uses unidirectional chains, lifting products from below.

NEST technology innovates the traditional pliers: in addition to having all the peculiarities of a bottom-gripping plier, thanks to which the product is supported and not crushed, stressed or deformed by contact, NEST has the advantage of having the same overall dimensions both in withdrawal and in storage. This makes it possible to have up to 50% less space than a parallel opening gripper and to be able to create multi-line and multi-product palletizing solutions in smaller spaces.

NEST is fast, precise and reliable even in harsh environmental conditions, for example in dusty or wet surroundings. All movements are servo-motorized to obtain maximum precision and speed and it is made entirely of aluminium and carbon to reduce weight without decreasing its strength.

IMA TMC: YOUR PARTNER FOR TISSUE AND NONWOVEN PACKAGING SOLUTIONS

For 20 years, IMA TMC has been offering the most innovative solutions to handle and solve the complexities related to the packaging and handling of Tissue and Personal Care products.

Our specialization is a nodal aspect that distinguishes the approach and method of IMA TMC: for every kind of request, we can count on dedicated and skilled resources, distinguishing two areas of expertise:

- “Standard” flexible machines for packaging

- Tailor-made design and manufacture of complete lines

For every manufacturing request, IMA TMC can offer prompt answers and technological solutions.